07 work cable and ground connections – Tweco 1000 Merlin(Sept1999) User Manual

Page 22

INSTALLATION PROCEDURES

18

Manual 0-2731

NOTE

Equipment ordered as a system will have the Torch

factory connected to the Power Supply.

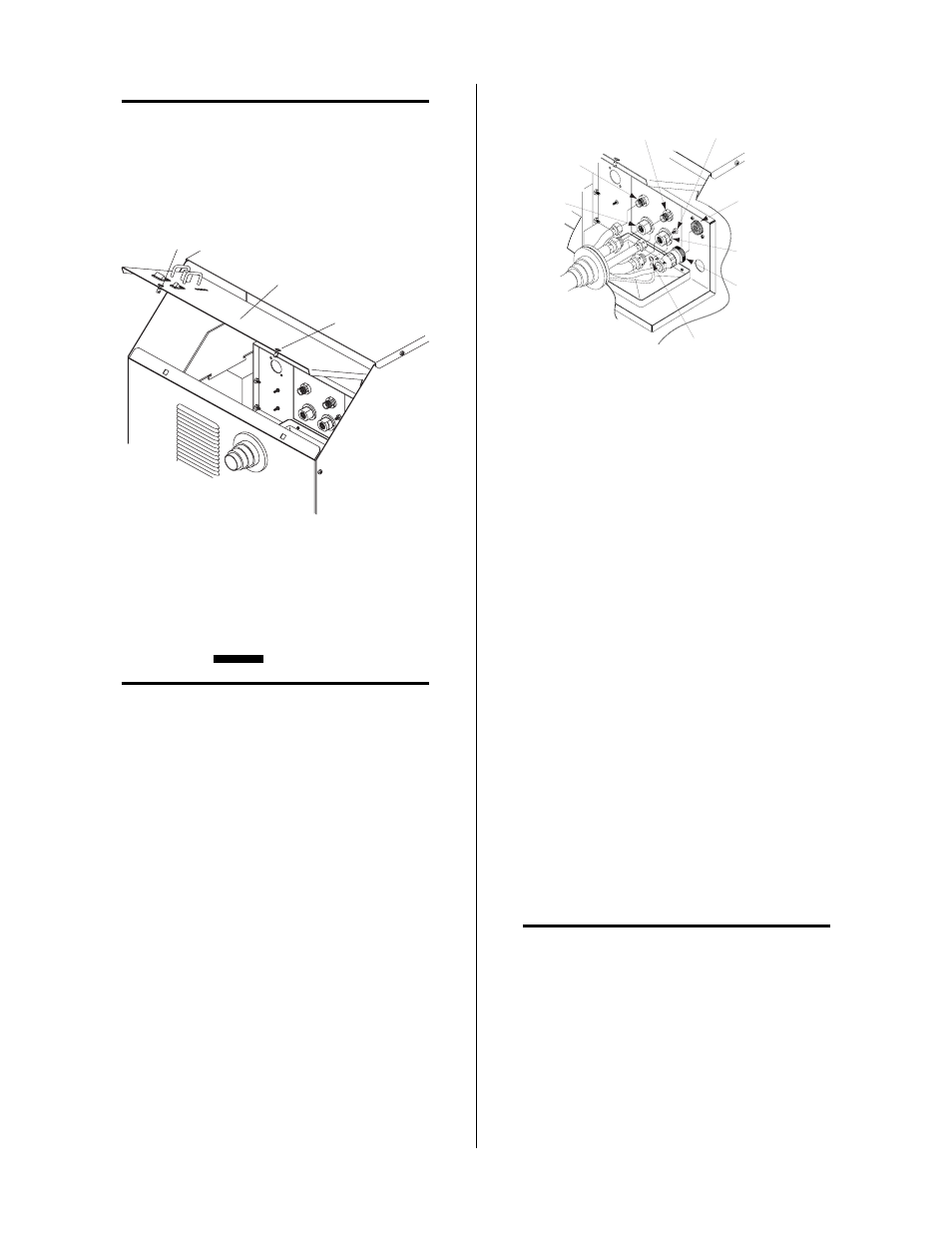

1. Turn the two latch screws securing the Control/Ac-

cess Panel to the power supply front panel.

Control/Access Panel

Latch Screw

Latch Screw

A-02165

Figure 3-7 Front Control/Access Panel

2. Lift up on the Control/Access Panel to gain access to

the torch bulkhead panel.

CAUTION

This system is designed for use with the Maximizer

300 Torch only. Do not connect any other torch to

this power supply.

3. Feed the end of the CNC/Remote Pendant Control

Cable, if used, through the rubber boot in the front

panel.

4. Connect the CNC/Remote Pendant Cable to Control

Cable Connector.

A-02271

Secondary

Gas

Plasma (+)

Gas

Control

Cable

Connector

Coolant

Return (-)

Coolant

Supply

Control

Cable

Connector

Torch Leads

Shield Stud

Ring Lug

(Shielded Torches Only)

Figure 3-8 Torch Leads Connections

5. Feed the end of the torch leads through the rubber

boot in the front panel.

6. Connect torch coolant and gas leads to the connectors,

as indicated on bulkhead.

7. Remove one nut and star washer fron the torch lead

shield stud.

8. Place the ring lug from the torch lead shield wire over

the stud and secure with the nut and star washer.

9. Close the access panel and turn the two latching screws.

3.07 Work Cable And Ground

Connections

A. Electromagnetic Interference (EMI)

Pilot arc initiation generates a certain amount of electro-

magnetic interference (EMI), commonly called RF noise.

This RF may interfere with other electronic equipment

such as CNC controllers, etc. To minimize RF interfer-

ence, follow these grounding procedures when install-

ing mechanized systems:

B. Creating an Earth Ground

NOTE

Refer to Appendix III for typical system ground-

ing diagram.

1. Install a ground wire (not included) between the sys-

tem and a solid earth ground (also called star ground).

To create a solid earth ground, drive a 1/2 in (12 mm)

diameter copper rod at least 6 - 8 ft (1.8 - 2.4 m) into

the earth so that the rod contacts moist soil over most

of its length. The required depth will vary depend-

ing on location (see NOTE). Locate the rod as close as