Tweco 1000 Merlin(Sept1999) User Manual

Page 19

Manual 0-2731

15

INSTALLATION PROCEDURES

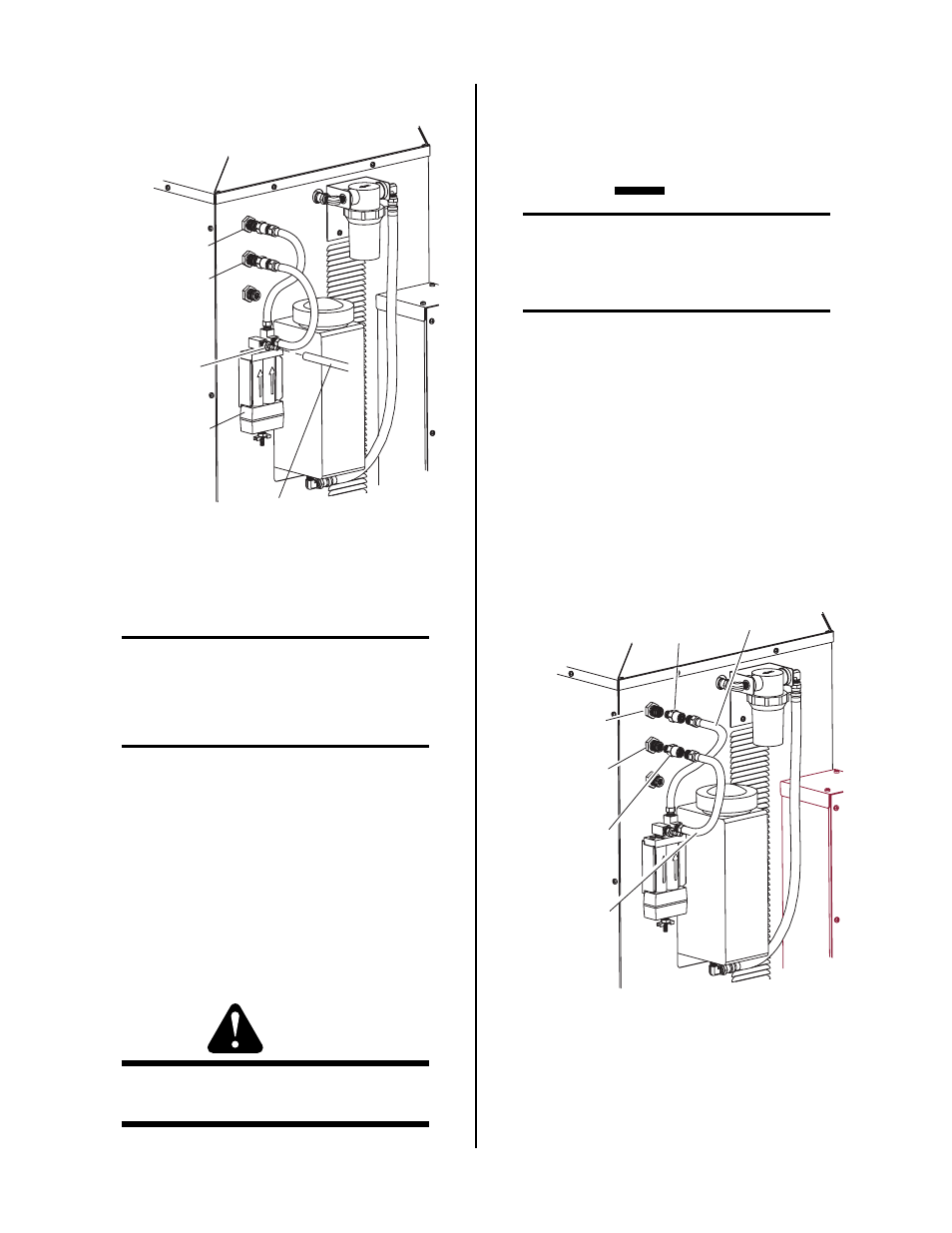

A-02348

Air Supply Hose

(Customer Supplied)

Two-Stage

Air Filter

PLASMA GAS

SECONDARY

GAS

Barb Fitting

Figure 3-1 Supply Hose Connections

NOTE

The supply hose must be 1/4 inch (6.3 mm) mini-

mum inside diameter to provide adequate air flow.

B. Using High-Pressure Gas Cylinders

NOTES

Refer to the regulator manufacturer’s specifications

for installation and maintenance procedures. Re-

fer to Section 6.05, System Options and Accesso-

ries, or a listing of available high-pressure regula-

tors.

Do not use an air line filter with high pressure gas

cylinders.

1. Examine the cylinder valves to be sure they are clean

and free of oil, grease or any foreign material. Mo-

mentarily open each cylinder valve to blow out any

dust which may be present.

WARNING

Do not stand in front of the valve outlet when open-

ing.

2. Each cylinder must be equipped with an adjustable

high-pressure regulator capable of pressures up to 125

psi (8.6 BAR) maximum and flows of up to 700 scfh

(328 lpm) for cutting or gouging.

CAUTION

Maximum input pressure to the internal regula-

tor on the Power Supply must not exceed 125 psi

(8.6 BAR).

NOTE

A typical 50 lb. CO2 cylinder can deliver a con-

tinuous flow rate of 35 scfh (16.5 lpm). To obtain

the required flow rate for the torch, it may be nec-

essary to manifold several CO2 cylinders. Con-

tinuous flow requirements will depend on the spe-

cific application and duty cycle.

3. Connect the gas supply to the Power Supply per

the following:

a. Remove the plasma and secondary gas hoses

and adapters from the PLASMA and SECOND-

ARY fittings at the rear panel.

PLASMA GAS

Fitting

SECONDARY

GAS Fitting

Plasma Gas

Hose

Secondary Gas

Hose

Adapter

Fitting

A-02355

Adapter Fitting

Figure 3-2 Removal Of Factory Installed Hardware

b. Connect the gas hose from the plasma gas

source directly to the input fitting on the rear

panel of the Power Supply marked PLASMA.