Tweco 1000 Cutting Systems User Manual

Page 16

INTRODUCTION

2-2

Manual 0-2710

2. Torch Leads Length

• 10 ft (3.05 m)

• 15 ft (4.57 m)

• 20 ft (6.1 m)

• 25 ft (7.6 m)

• 50 ft (15.2 m)

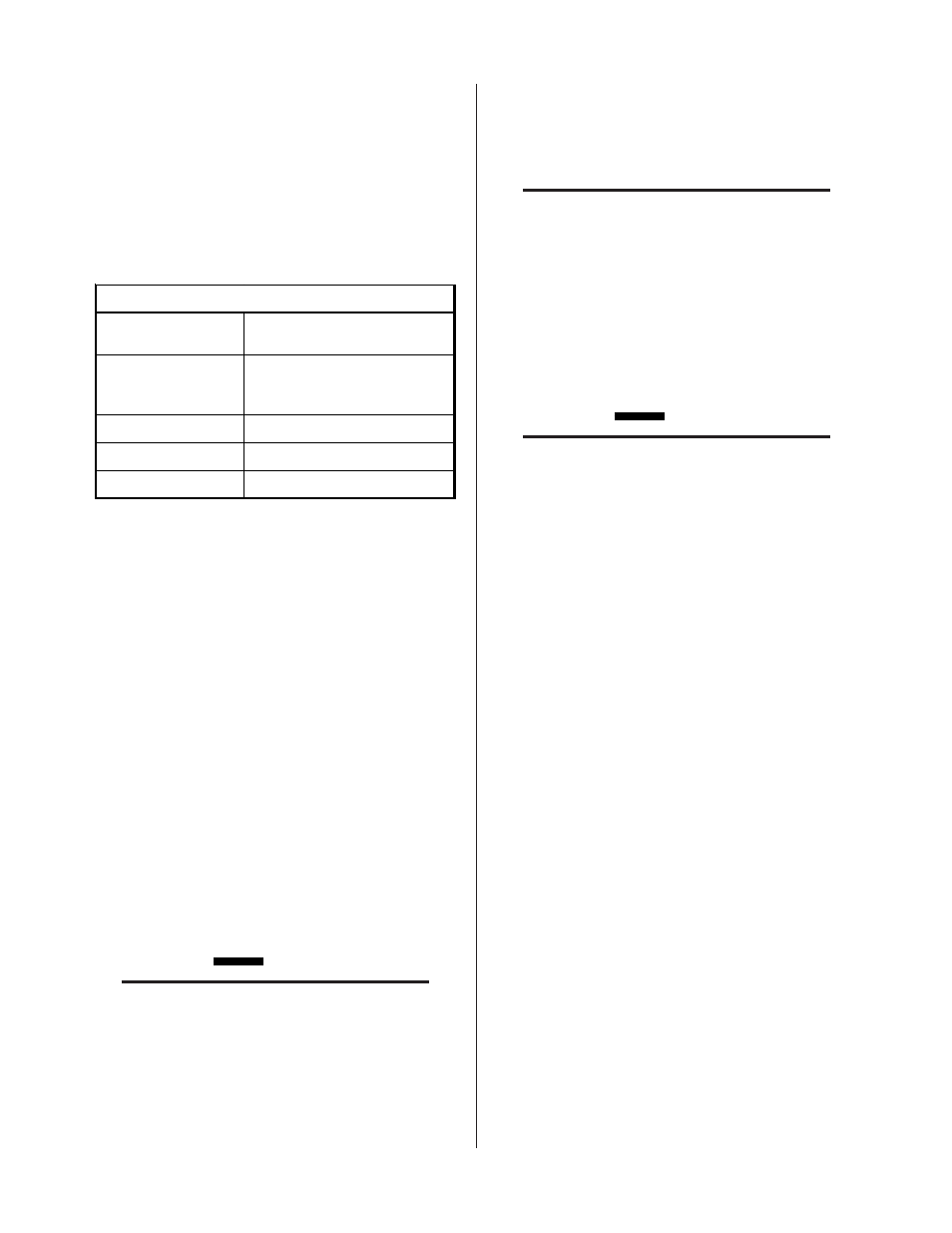

3. Torch Ratings

Ambient

Temperature

104° F

(40° C)

Duty Cycle

100% @ 100 Amps @ 0.5 gpm

(1.91 lpm) Coolant Flow Rate

Maximum Current

100 Amps

Voltage (V

peak

)

500V

Arc Striking Voltage

12 kV

Torch Ratings

4. Cutting Range

Most materials up to 1-1/2 inches (38.1 mm)

Up to 1/2 inch (12.7 mm) for production speed cut-

ting

5. Pierce Rating

1/2 inch (12.7 mm)

6. Transfer Distance

3/8 inch (10 mm)

7. Torch Parts

Gas Distributor, Electrode, Tip, Shield Cup Body, End

Cap

8. Plasma Gas Requirements

a. Plasma Gas:

Compressed Air, Oxygen (O

2

), Ni-

trogen (N2), or Argon/Hydrogen(ArH2)

b. Pressure:

75 to 100 psi (4.8 to 6.9 bar)

CAUTION

Maximum input gas pressure must not exceed 125

psi (8.6 bar)

c. Cold Flow

Cutting: 60 - 90 scfh (28.3 - 42.5 lpm)

scfh = standard cubic feet per hour

NOTE

Cold flow is measured before the main arc is acti-

vated. When pressure is set correctly the plasma

gas flow rate is significantly lower when the arc is

initiated.

9. Secondary Gas Requirements

a. Secondary Gas:

Compressed Air, Carbon Diox-

ide (CO

2

), or Nitrogen (N2)

b. Pressure:

15 to 60 psi (1.0 to 4.1 bar)

CAUTION

Maximum input gas pressure must not exceed 125

psi (8.6 bar)

c. Flow

Cutting or Gouging: 15 to 220 scfh (7 to 103 lpm)

scfh = standard cubic feet per hour

10. Secondary Water Requirements

a. Water Source

: Tap Water

b. Water Pressure:

Min. 50 psi (3.5 bar)

c. Water Flow

: Cutting: 6 - 8 gph (35 - 47 lph)

11. Weight (without leads)

1.0 lb (.45 kg)