Cutmaster a40, a60 – Tweco A40-A60 CutMaster User Manual

Page 37

CUTMASTER A40, A60

Manual 0-5120

OPERATION

4T-3

4T.03 Automation Torch Parts Selection

Check the torch for proper consumable parts. The

parts supplied in the torch may not be correct for

the operator’s chosen amperage level. The torch

parts must correspond with the type of operation.

Torch parts:

Shield Cup, Cutting Tip, Electrode and Starter

Cartridge

NOTE

Refer to Sections 4T.08 and following for ad-

ditional information on torch parts.

Change the torch parts for a different operation as

follows:

4T.04 Cut Quality

NOTES

Cut quality depends heavily on setup and pa-

rameters such as torch standoff, alignment with

the workpiece, cutting speed, gas pressures, and

operator ability.

Cut quality requirements differ depending on applica-

tion. For instance, nitride build - up and bevel angle

may be major factors when the surface will be welded

after cutting. Dross - free cutting is important when

finish cut quality is desired to avoid a secondary clean-

ing operation. The following cut quality characteristics

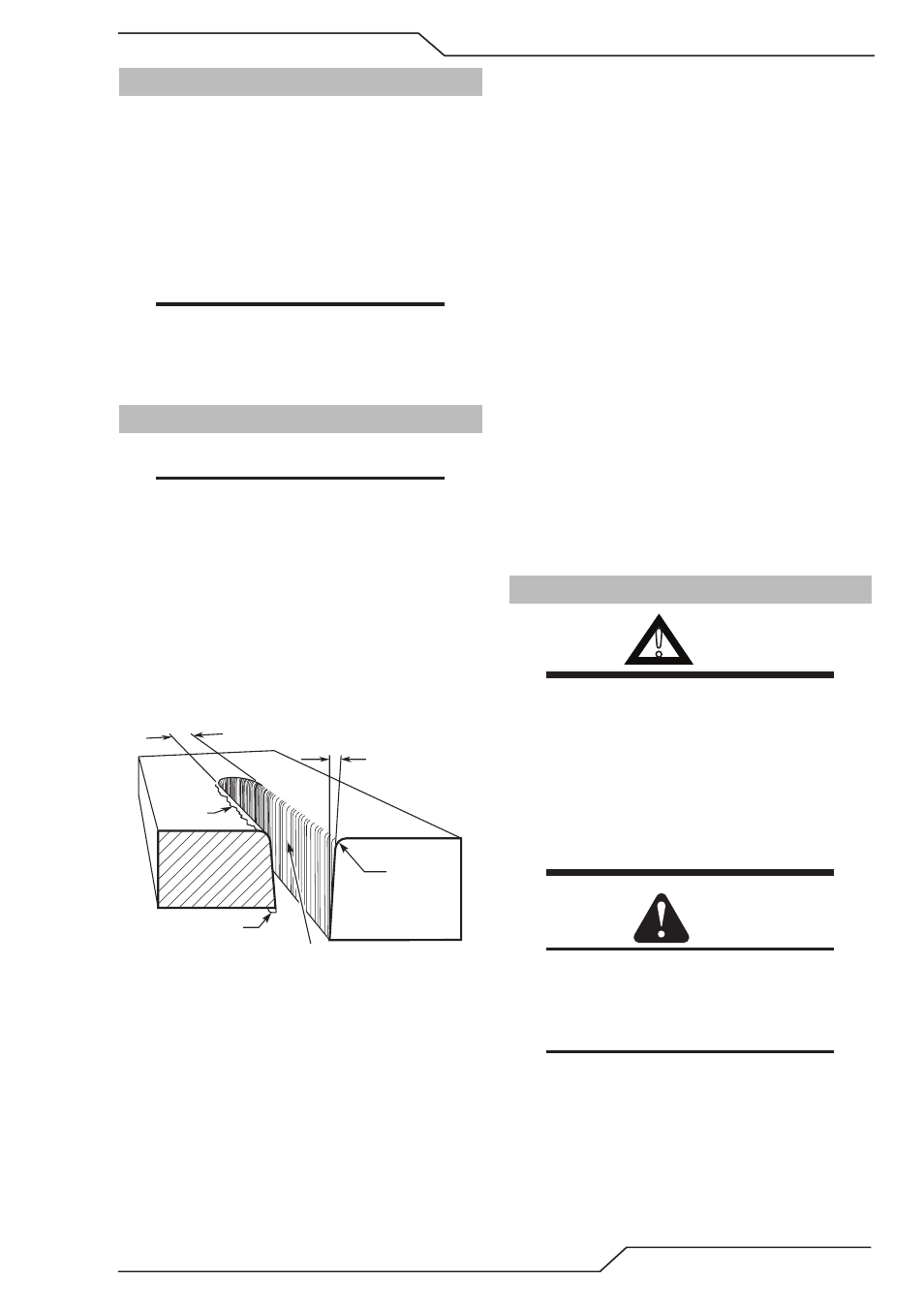

are illustrated in the following figure:

Kerf Width

Cut Surface

Bevel Angle

Top Edge

Rounding

Cut Surface

Drag Lines

Dross

Build-Up

Top

Spatter

A-00007

Cut Quality Characteristics

Cut Surface

The desired or specified condition (smooth or

rough) of the face of the cut.

Nitride Build - Up

Nitride deposits can be left on the surface of the cut

when nitrogen is present in the plasma gas stream.

These buildups may create difficulties if the mate-

rial is to be welded after the cutting process.

Bevel Angle

The angle between the surface of the cut edge and

a plane perpendicular to the surface of the plate.

A perfectly perpendicular cut would result in a

0° bevel angle.

Top - Edge Rounding

Rounding on the top edge of a cut due to wearing

from the initial contact of the plasma arc on the

workpiece.

Bottom Dross Buildup

Molten material which is not blown out of the

cut area and resolidifies on the plate. Excessive

dross may require secondary cleanup operations

after cutting.

Kerf Width

The width of the cut (or the width of material

removed during the cut).

Top Spatter (Dross)

Top spatter or dross on the top of the cut caused by

slow travel speed, excess cutting height, or cutting

tip whose orifice has become elongated.

4T.05 General Cutting Information

!

WARNING

Disconnect primary power at the source before

disassembling the power supply, torch, or torch

leads.

Frequently review the Important Safety Pre-

cautions at the front of this manual. Be sure

the operator is equipped with proper gloves,

clothing, eye and ear protection. Make sure no

part of the operator’s body comes into contact

with the workpiece while the torch is activated.

CAUTION

Sparks from the cutting process can cause dam-

age to coated, painted, and other surfaces such

as glass, plastic and metal.

NOTE

Handle torch leads with care and protect them

from damage.

Piloting

Piloting is harder on parts life than actual cutting

because the pilot arc is directed from the electrode

to the tip rather than to a workpiece. Whenever

possible, avoid excessive pilot arc time to improve

parts life.