Cutmaster a40, a60 – Tweco A40-A60 CutMaster User Manual

Page 33

CUTMASTER A40, A60

Manual 0-5120

OPERATION

4-3

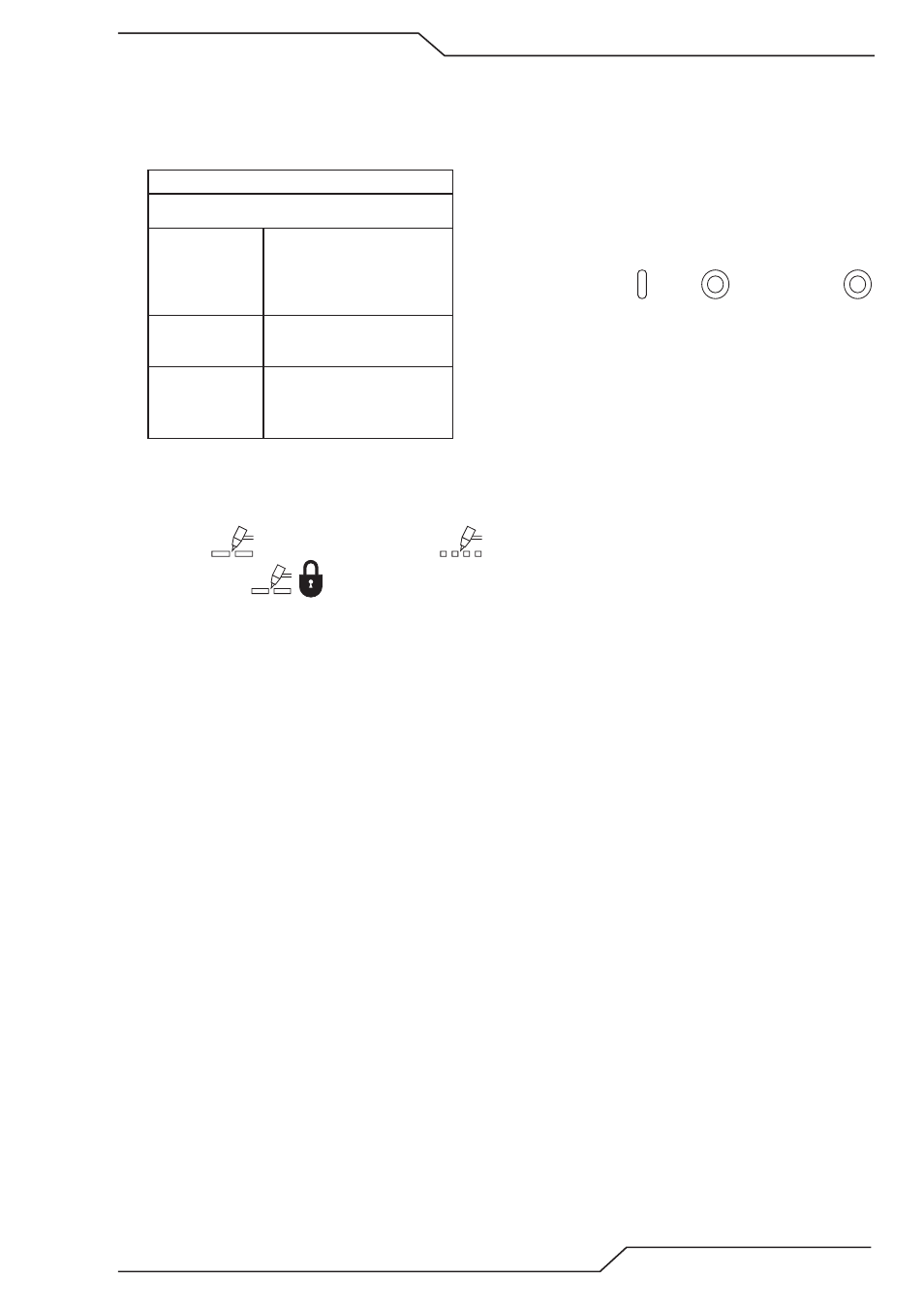

3. For Drag cutting, adjust gas pressure from

75 - 95 psi / 5.2 - 6.5 bar (LED's in center of

control panel). Refer to the Drag Cutting chart

for pressure setting details.

DRAG

Gas Preassure Settings

Leads

Length

SL100

(Mechanized Torch)

SL 100 SV

(Automated Torch)

Up to 25'

(7.6 m)

80 psi

5.5 bar

Each Additional

25' (7.6 m)

Ad 5 psi

0.4 bar

Select Current Output Level

1. Place the Function Control Knob in one

of the three operating positions available:

RUN

, RAPID AUTO RESTART

or

LATCH

. Gas flow stops.

2. Set the output current to desired amperage

with the Output Current Control Knob.

Cutting Operation

When the torch leaves the workpiece during cut-

ting operations with the Function Control Knob

in the RUN position, there is a brief delay in re-

starting the pilot arc. With the knob in the RAPID

AUTO RESTART position, when the torch leaves

the workpiece the pilot arc restarts instantly, and

the cutting arc restarts instantly when the pilot

arc contacts the workpiece. (Use the 'Rapid Auto

Restart' position when cutting expanded metal or

gratings, or in gouging or trimming operations

when an uninterrupted restart is desired). And

with the knob in the LATCH position the main

cutting arc will be maintained after the torch

switch is released.

Typical Cutting Speeds

Cutting speeds vary according to torch output

amperage, the type of material being cut, and op-

erator skill. Refer to Section 4T.08 and following

for greater details.

Output current setting or cutting speeds may be

reduced to allow slower cutting when following

a line, or using a template or cutting guide while

still producing cuts of excellent quality.

Postflow

Release the trigger to stop the cutting arc. Gas

continues to flow for approximately 20 seconds.

During post - flow, if the user moves the trigger

release to the rear and presses the trigger, the pilot

arc starts. The main arc transfers to the workpiece

if the torch tip is within transfer distance to the

workpiece.

Shutdown

Turn the ON / OFF

switch to OFF

(down). All Power Supply indicators shut off.

Unplug the input power cord or disconnect input

power. Power is removed from the system.