Accessories maintenance – Triton SJA 200 User Manual

Page 9

8

GB

Accessories / Maintenance

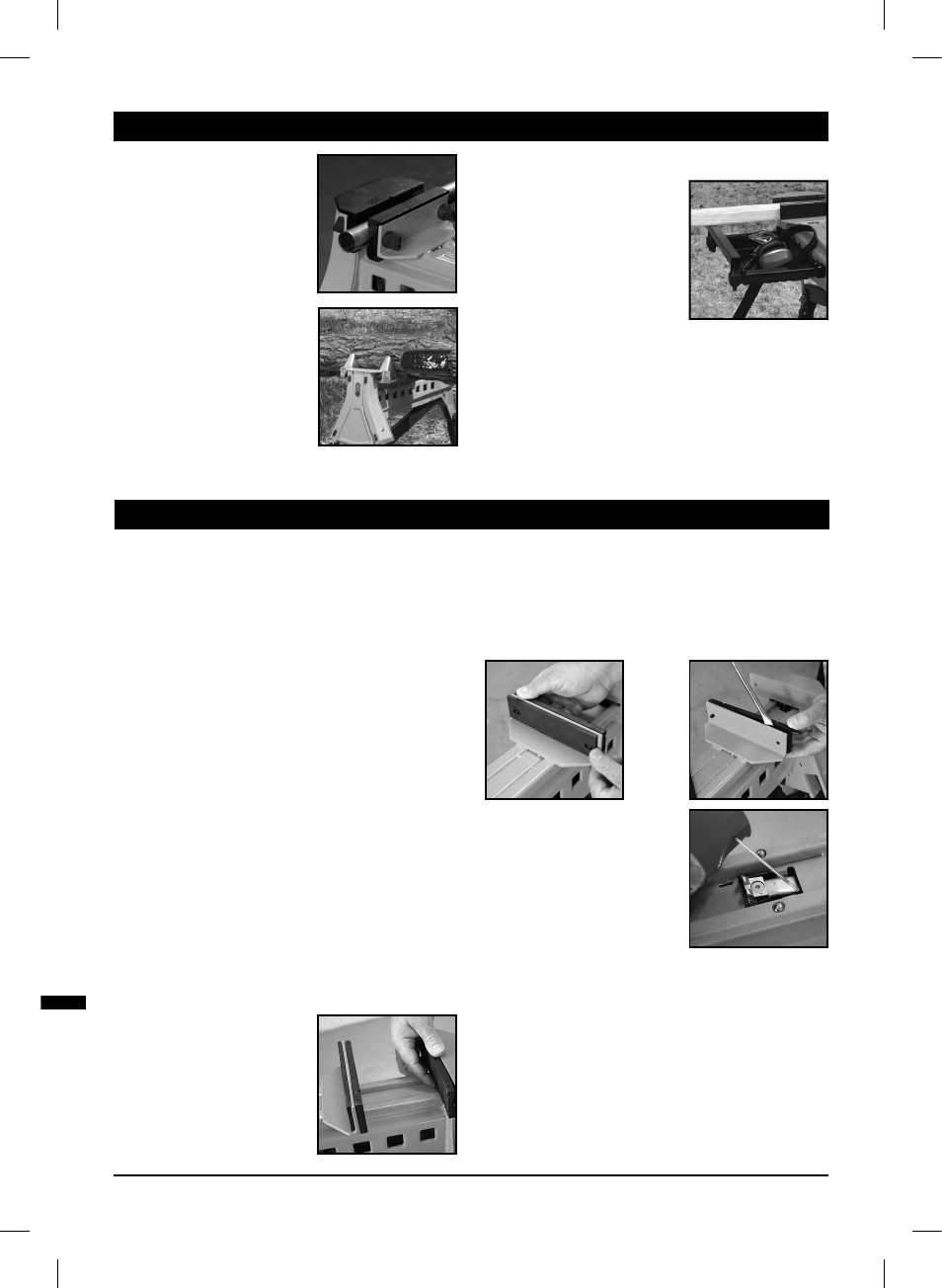

Engineers’ Jaws SJA470

• The bolt-on jaws are

manufactured from extremely

strong ductile cast iron, and are

specially shaped to increase grip

when clamping pipe or round

sections up to 50mm in diameter.

They also have an integral anvil

for hammering or bending of

heavy metal sections

Log Jaws SJA460

• Suitable for gripping logs or

poles, these jaws also bolt onto

the standard steel jaws and are

formed from steel plate, and zinc-

plated for corrosion resistance

Note: Logs or poles up to 175mm in

diameter are gripped firmly for chain

sawing, drilling, rebating etc.

ACCESSORIES

MAINTENANCE

Extension Tray SJA420

• The Extension Tray fits through

the Extension Tray Mounting Holes

(12) in either side of the main

Body (4). It provides outboard

support for the workpiece,

keeping it level while clamping

into position. A tough, high density

polyethylene tray locates onto the

support tubes as a convenient

place to hold tools, parts and

other accessories

Note: For additional support and capacity a second extension tray

can be fitted onto the opposite side of SuperJaws

Note: Check with your Triton stockist for additional accessories for

your SuperJaws. Spare parts for your SuperJaws can be obtained

from toolsparesonline.com.

• Basic maintenance of this product should ensure a long

working life

• Any damage to SuperJaws should be repaired and carefully

inspected before use by qualified repair personnel

• Servicing should be carried out using only original Triton

replacement parts

• Triton Tools will not be responsible for any damage or injury

caused by unauthorised repair or mishandling of the machine

Please note:

• Depending on the type of use, it is quite likely this product will

receive scratches and marks that will remove paint and result in

corrosion over time. Check for corrosion and treat if necessary.

Some disassembly may be required to check thoroughly, such

as the underside of the moving jaw. Always dry SuperJaws if it

gets wet, particularly on any exposed metal surfaces

• Lubricant or grease may be required from time to time, but

always apply it in moderation and never apply lubricant if it will

affect the way the product operates. Any mechanism should

only be lubricated with a light spray lubricant which cannot

affect the way it operates

• If SuperJaws becomes damaged or corroded, and requires

major repair, such as welding, you can no longer rely on the

given figures for clamping force or load capacity. Under these

circumstances, SuperJaws should be replaced immediately, as

this level of repair will void the guarantee

REMOVING THE URETHANE JAW FACES

• The jaw facings can be removed

to achieve a greater clamping

range, or for replacement if worn

or damaged, or when fitting the

optional jaws

Note: Replacement urethane jaw

pads are available from your

Triton stockist or from www.

toolsparesonline.com.

1. The Fixed Jaw Urethane Face (1) is removed by carefully prying

it off the Fixed Jaw (14) using a broad screwdriver or similar

2. To remove the Moving Jaw Urethane Faces (2), push the

backing face to the right (when viewed from the front of

SuperJaws), in order to disengage the connection pins. The

backing face can then be removed, allowing the front to be

pulled off the Moving Jaw (15)

• The pawl carrier pivot pin may

occasionally require a small

amount of spray lubricant, as

shown, if it doesn’t pivot smoothly

STORAGE

• Store this tool carefully in a

secure, dry place out of the reach

of children

DISPOSAL

Always adhere to national regulations when disposing of tools that

are no longer functional and are not viable for repair

• Do not dispose of tools, with household waste

• Contact your local waste disposal authority for information on

the correct way to dispose of tools

SJA200_Z1MANPRO2.indd 8

31/03/2014 11:19