Operation – Triton SJA 200 User Manual

Page 7

6

GB

Operation

BASIC OPERATION

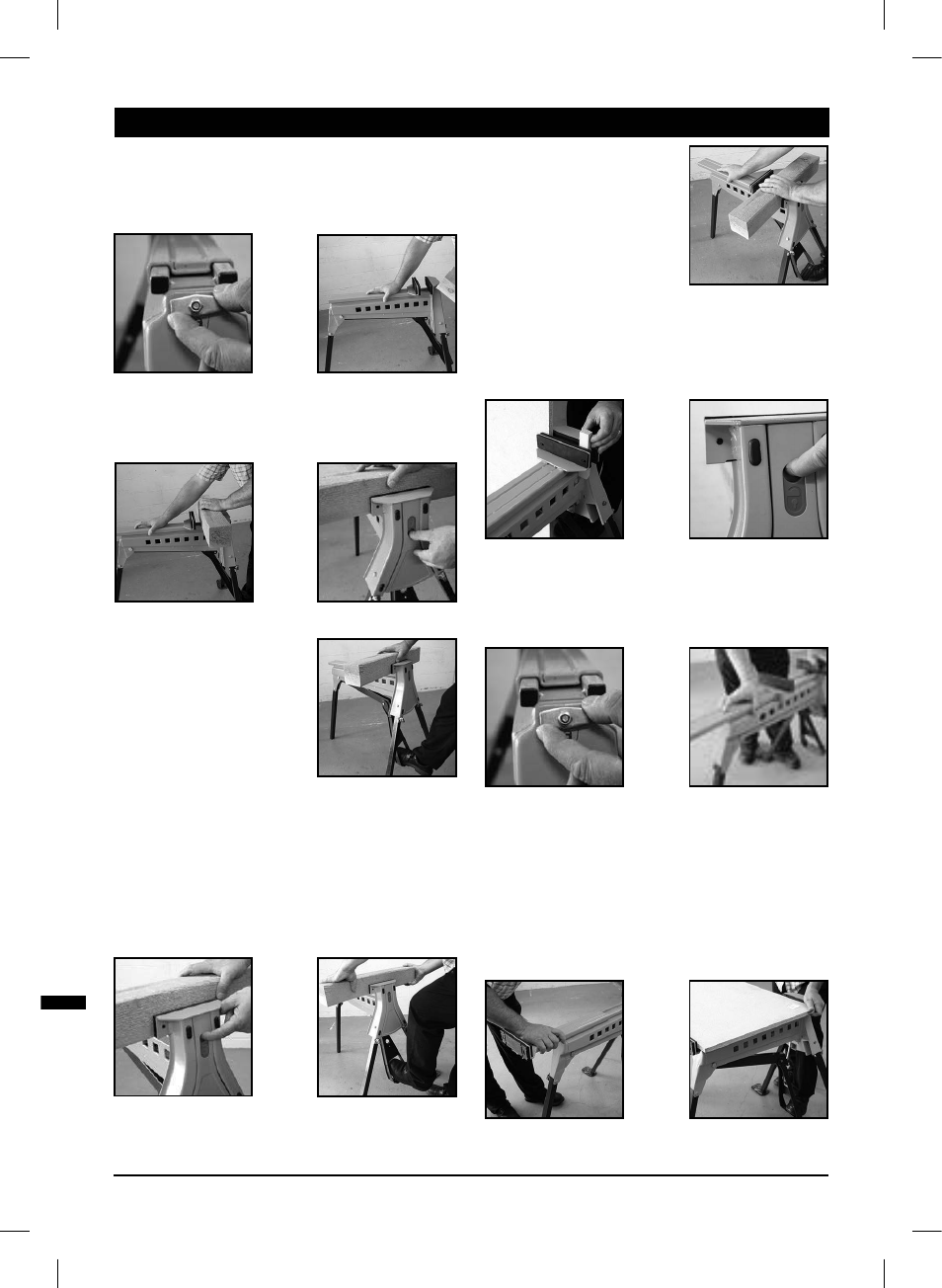

Clamping

1. Check that the Moving Jaw Locking Tab (3) is set to the

‘horizontal’ position, and push the Moving Jaw (15) back until

your workpiece fits between the jaws

2. Place the workpiece against the Fixed Jaw (14) and slide the

moving jaw forward until it touches the workpiece

Note: The jaw can also be advanced forward by pressing the Foot

Pedal (8) repeatedly.

3. Slide the Lock / Release Switch (13) down to the ‘lock’ position

Note: If preferred the switch can be

locked after the work is clamped.

4. Apply downward pressure on

the Foot Pedal (8) until sufficient

clamping force has been applied

Note: For extra force you may stand

on the Foot Pedal (maximum 100kg),

but do not jump on it, as you could

damage the unit.

Releasing

1. Slide the Lock / Release Switch (13) up to the ‘release’ position

2. Push on the Foot Pedal (8) then allow it to return up and release

the workpiece

Note: Ensure you are supporting the workpiece to prevent it from

falling once the jaw is released.

Note: If you have clamped the object very tightly, you may need to

exert more pressure on the Foot Pedal before it will release.

OPERATION

3. Slide the Moving Jaw (15) back,

and remove your workpiece

ADVANCED OPERATION

Clamping on one side of the jaw

• Some large or awkward

workpieces can only be clamped

on one side of the jaws

Note: Always fit a spacer (the same thickness as your workpiece)

to the other side of the jaws, to prevent the Moving Jaw (15) from

skewing.

Clamping large objects (460mm to 956mm)

• The Moving Jaw (15) can be reversed to accommodate

workpieces measuring between 460mm and 956mm:

1. Set the Lock / Release Switch (13) to the ‘release’ position, and

ensure that the Foot Pedal (8) is released

2. Check the Moving Jaw Locking Tab (3) is in the horizontal

position

3. Slide the Moving Jaw fully from its tracks

4. Rotate the Moving Jaw by 180°, and re-insert it into the tracks

Notes:

• When clamping objects with the Moving Jaw (15) reversed,

ensure the workpiece sits down onto, and is parallel to, the

sliding jaw. Avoid clamping workpieces at the top of the jaws

(with a gap between the workpiece and the base of the Moving

Jaw) as excessive pedal pressure could damage the unit

• When clamping large or heavy materials, provide outboard

support (such as a MSA200 Triton Multi-Stand) to prevent

SuperJaws from tipping over

SJA200_Z1MANPRO2.indd 6

31/03/2014 11:19