Wiring the outdoor sensor 070, Mounting the boiler and mix sensor 082 – tekmar 402 House Control Installation User Manual

Page 8

© 2010

D 402 - 09/10

8 of 32

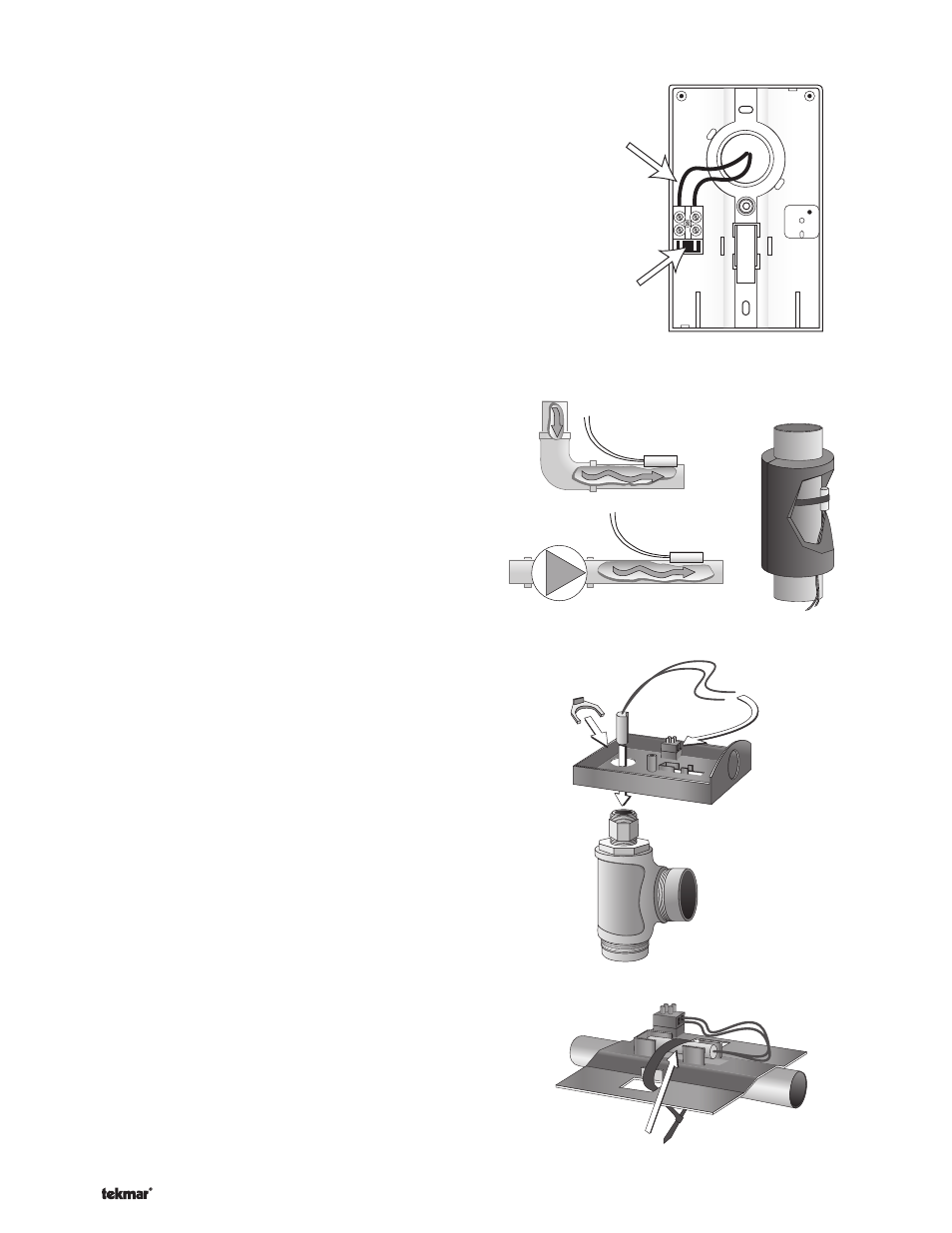

Connect 18 AWG or similar wire to the two terminals

provided in the enclosure and run the wires from the

070 to the control. Do not run the wires parallel to tele-

phone or power cables. If the sensor wires are located

in an area with strong sources of electromagnetic in-

terference (EMI), shielded cable or twisted pair should

be used or the wires can be run in a grounded metal

conduit. If using shielded cable, the shield wire should

be connected to the Com or Com Sen terminal on the

control and not to earth ground.

Follow the sensor testing instructions in this brochure

and connect the wires to the control.

Replace the front cover of the sensor enclosure.

•

•

•

Wiring the Outdoor Sensor 070 -----------------------------------------------------------------------

-----------------------------------------------------------------------

Wires from outdoor

sensor to control

terminals

(Com Sen - Out Sen)

Sensor is built into

the enclosure

Mounting the Boiler and Mix Sensor 082 -------------------------------------------------------------

-------------------------------------------------------------

Note: These sensors are designed to mount on a pipe or

in a temperature immersion well.

The Universal Sensor should be placed downstream of a

pump or after an elbow or similar fitting. This is especially

important if large diameter pipes are used as the thermal

stratification within the pipe can result in erroneous sensor

readings. Proper sensor location requires that the fluid

is thoroughly mixed within the pipe before it reaches the

sensor.

Strapped to Pipe

The Universal Sensor can be strapped directly to the pipe

using the cable tie provided. Insulation should be placed

around the sensor to reduce the effect of air currents on

the sensor measurement.

Immersion Well

If a Universal Sensor is mounted onto 1” (25 mm) diameter

L type copper pipe, there is approximately an 8 second

delay between a sudden change in water temperature and

the time the sensor measures the temperature change.

This delay increases considerably when mild steel (black

iron) pipe is used. In general, it is recommended that

a temperature well be used for steel pipe of diameter

greater than 1-1/4” (32 mm). Temperature wells are also

recommended when large diameter pipes are used and

fluid stratification is present.

Conduit Connection

The Universal Sensor 082 and Universal Sensor Enclosure

080 (sold separately) are specifically designed to mount

onto a 3/8” (10 mm) ID temperature well that is supplied

with an end groove. To install the well, plumb a ‘T’ into the

pipe and fix the well into the ‘T’. The 080 enclosure has

a 7/8” (22 mm) back knockout that must be removed and

fitted over the temperature well. The 082 is then inserted

into the well and the retaining clip supplied with the

enclosure is snapped onto the well end groove. If the well

has a threaded end, the installer must supply a standard

threaded conduit retaining ring. The two wires from the

sensor are connected to the terminal block provided in the

enclosure. The other side of the terminal block is used to

connect wires from the control.

Bottom of

Enclosure 080

Universal

Sensor 082

Cable Tie

Sensor Well

Retaining Clip

Universal

Sensor 082