Sequence of operation – tekmar 261 Boiler Control User Manual

Page 4

Copyright © D 261 - 0

3/09

4 of 20

Sequence of Operation

Section A

General Operation

Page 4

Section B

Boiler Reset

Page 5-8

Section C

Setpoint

Page 8

Section A — General Operation

POWERING UP THE CONTROL

When the Boiler Control 261 is powered up, the control displays the control type number in the LCD for 2 seconds. Next, the software

version is displayed for 2 seconds. Finally, the control enters into the normal operating mode and the LCD defaults to displaying the

current outdoor air temperature.

OPERATION

The 261 operates two on / off heat sources to control the supply water

temperature to a hydronic system. The supply water temperature is based

on either the current outdoor temperature, or a fixed setpoint.

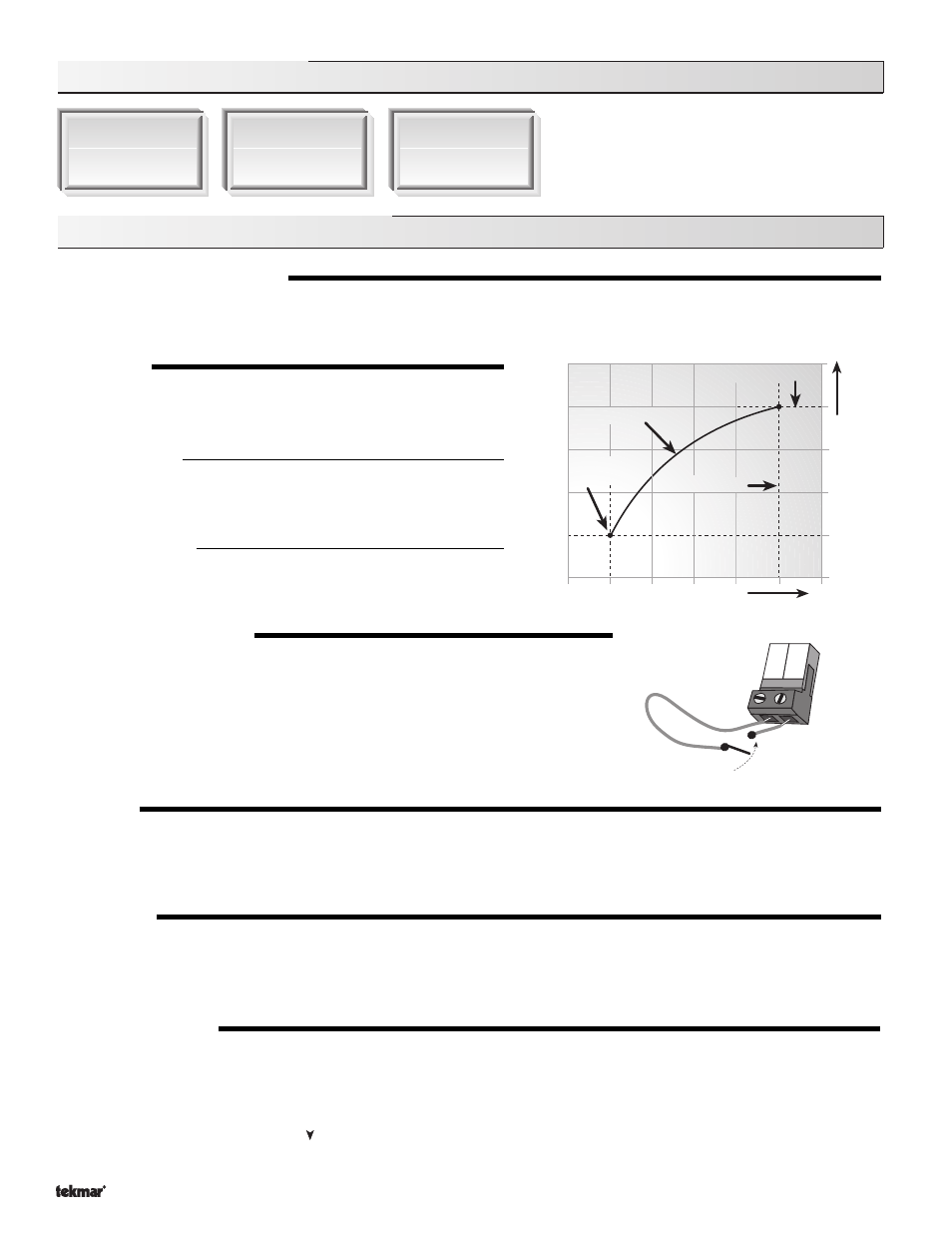

Outdoor Reset

When a demand signal from the heating system is present, the 261

calculates a supply temperature based on the outdoor air tempera-

ture and

Characterized Heating Curve settings.

Setpoint Control

When a demand signal from a setpoint system is present, the control

operates the boiler(s) to maintain the supply water temperature at the

Setpoint setting. Refer to section C.

SETBACK (UNOCCUPIED)

To provide greater energy savings, the 261 has a setback capability. With setback, the

supply water temperature in the system is reduced when the building is unoccupied. By

reducing the supply water temperature, air temperature in the space may be reduced

even when thermostat(s) are not turned down. Any time the

UnO Sw (13) and the Com

(14) terminals are shorted together, the control operates in the unoccupied (Night) mode.

When in the unoccupied (Night) mode, the UNOCC segment is displayed in the LCD. The

261 adjusts the supply water temperature based on the UNOCC settings made in the control.

This feature has no effect when the control is used in setpoint operation.

ROTATION

The 261’s

Equal Run Time Rotation function is fixed at 48 hours. The firing order of the boilers changes whenever one stage accumulates

48 hours more running time than the other stage. After each rotation, the stage with the least running hours is the first to fire, and the

stage with the most running hours is the last to fire. This function ensures that both stages receive equal amounts of use. When the

Rotate / Off DIP switch is set to the Off position, Stage 1 is always the first stage to fire.

EXERCISING

The 261 has a built-in exercising function. If the pump has not been operated at least once every 3 days, the control turns on the

output for 10 seconds. This minimizes the possibility of the pump seizing during a long period of inactivity. While the control is

exercising, the

Test LED flashes.

Note: The exercising function does not work if power to the control or pump is disconnected.

FACTORY DEFAULTS

The control comes preset with several factory defaults. These defaults are based on the terminal unit selection (see section B2). To

fine-tune building requirements, these defaults may be changed. If a factory default value for a terminal unit is changed, the terminal

unit number will flash when selected in the ADJUST menu.

To reload the factory defaults listed in section B2, power down the control and wait for 10 seconds. Power up the control while

simultaneously holding the

Item and buttons. The terminal unit number should now be displayed constantly in the LCD rather

than flashing.

Outdoor Design

Increasing W

ater

T

emperature

Design Supply

Decreasing Outdoor Temperature

Terminal Unit

Indoor Design

13 14

Timer switch

UnO

Sw

Com