Dip switch settings – tekmar 261 Boiler Control User Manual

Page 12

Copyright © D 261 - 0

3/09

12 of 20

Test The Outputs

Boiler Pump (

Boil Pmp)

If the boiler pump is connected to the

Boil Pmp terminal (7), make

sure power to the terminal block is off, and install a jumper between

the

Power L and the Boil Pmp terminals (5 and 7). Install a second

jumper between

Power N and N terminals (6 and 8). When power is

applied to the

Power L and Power N terminals (5 and 6), the boiler

pump should start. If the pump does not turn on, check the wiring

between terminal block and pump, and refer to any installation or

troubleshooting information supplied with the pump. If the pump

operates properly, disconnect the power and remove the jumpers.

Stage 1 and 2

If the boiler circuit is connected to the

Stage 1 terminals (9 and 10) and / or Stage 2 terminals (11 and 12), make sure power to the

boiler circuit is off, and install a jumper between the terminals. When the boiler circuit is powered up, the boiler should fire. If the

boiler does not turn on, refer to any installation or troubleshooting information supplied with the boiler. (The boiler may have a flow

switch that prevents firing until the boiler pump is running). If the boiler operates properly, disconnect the power and remove the

jumper.

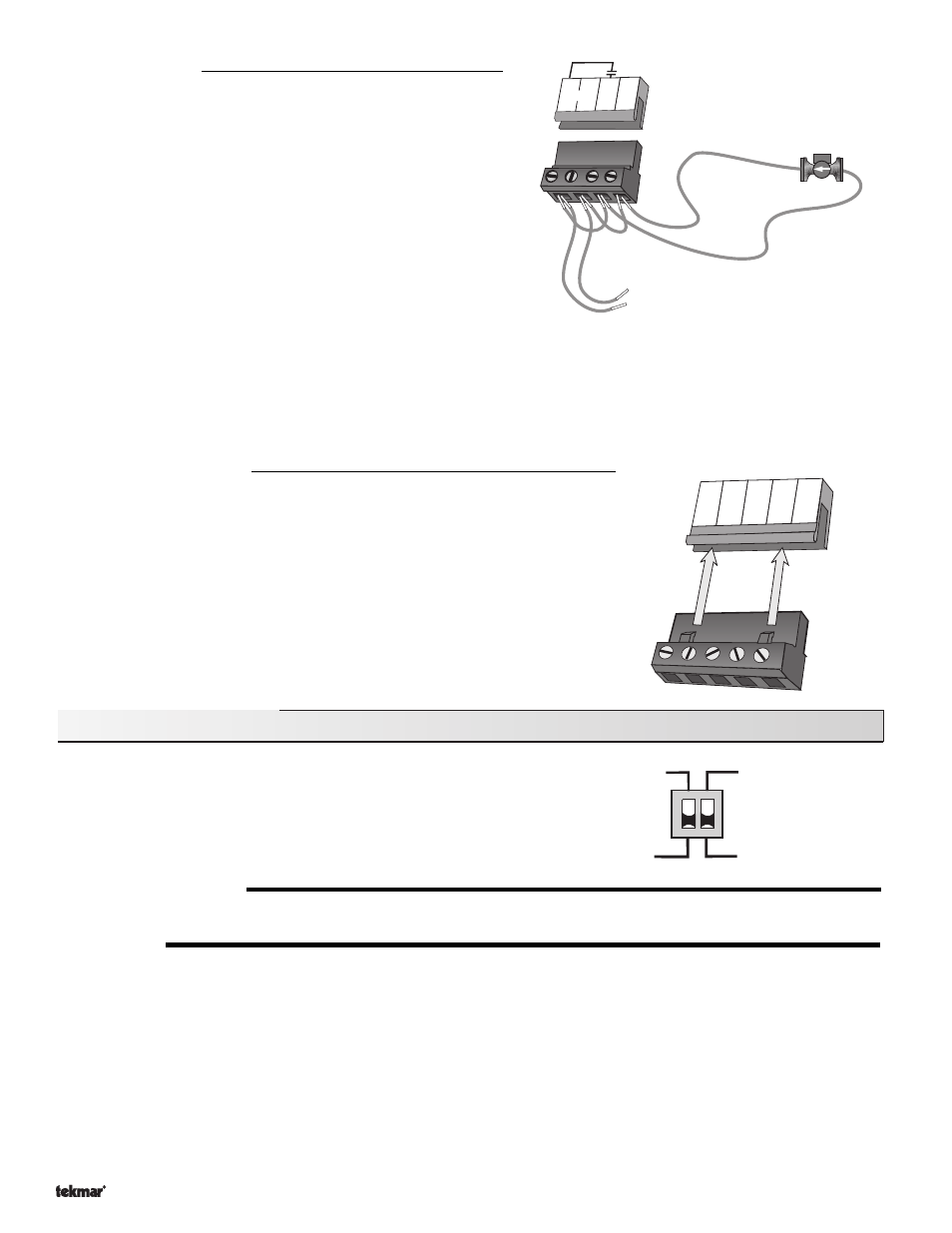

Connecting The Control

Make sure all power to the devices and terminal blocks is off, and remove any

remaining jumpers from the terminals.

Reconnect the terminal blocks to the control by carefully aligning them with their respective

headers on the control, and then pushing the terminal blocks into the headers. The

terminal blocks should snap firmly into place.

Install the supplied safety dividers between the unpowered sensor inputs and the powered

or 120 V (ac) wiring chambers.

Apply power to the control. The operation of the control on power up is described in the

Sequence of Operation section of this brochure.

DIP Switch Settings

The DIP Switch settings on the control are very important and should be

set to the appropriate settings prior to making any adjustments to the

control through the user interface. The DIP switch settings change the

items that are available to be viewed and / or adjusted in the user

interface.

ADVANCED / INSTALLER

The

Advanced / Installer DIP switch is used to select which items are available to be viewed and / or adjusted in the user interface.

ROTATE / OFF

The

Rotate / Off DIP switch enables rotation of the boiler stages based on the Equal Run Time Rotation function. This function occurs

whenever the lead boiler accumulates 48 hours more running time than the lag boiler. If a single Lo-Hi boiler is used, the DIP switch

must be set to the

Off position.

13 14 15

17

16

Uno

Sw

Com Boil Out Com

Return

Installer

Off

Rotate

Advanced

5

6

Boil

Pmp

7

8

N

Power

120 V (ac)

L

N

L

N

Boiler

pump