Installation – tekmar 157 Difference Setpoint Control User Manual

Page 8

©

2010 D

157

-

06/10

8

of

16

Improper installation and operation of this control could

result in damage to the equipment and possibly even

personal injury. It is your responsibility to ensure that this

control is safely installed according to all applicable codes

and standards. This electronic control is not intended

for use as a primary limit control. Other controls that are

intended and certified as safety limits must be placed into

the control circuit.

Caution

Installation

Step One — Getting Ready

Check the contents of this package. If any of the contents

listed are missing or damaged, please contact your

wholesaler or tekmar sales representative for assistance.

Type 157 includes: One Difference Setpoint Control 157, One

Universal Sensor 071, One Solar Sensor, 085, Data Brochures

D 157, D 070, D 085, D 001, Application Brochure A 157.

Note: Carefully read the details of the Sequence of

Operation to ensure that you have chosen the proper

control for your application.

The control is mounted in accordance with the instructions in the Data Brochure D 001.

Step Two — Mounting

Step Three — Rough-in Wiring

The variable speed pump and second pump wiring

terminates in the electrical box. All other wiring terminates

in the two wiring chambers on the control. Determine

whether the low voltage wiring enters the wiring chamber

through the back or the bottom of the control. The wiring

is roughed-in to the electrical box prior to installation of the

control (see Brochure D 001). Standard 18 AWG solid wire

is recommended for all low voltage wiring, and multi-strand

16 AWG wire is recommended for 120 V (ac) wiring.

Power must not be applied to any of the wires during

the rough-in wiring stage.

Install the Source Sensor 085 and Storage Sensor 071

according to the instructions in the Data Brochures D 085

and D 070, and run the wiring back to the control.

Run wires from the 24 V (ac) power to the control. Use a

clean power source to ensure proper operation.

•

•

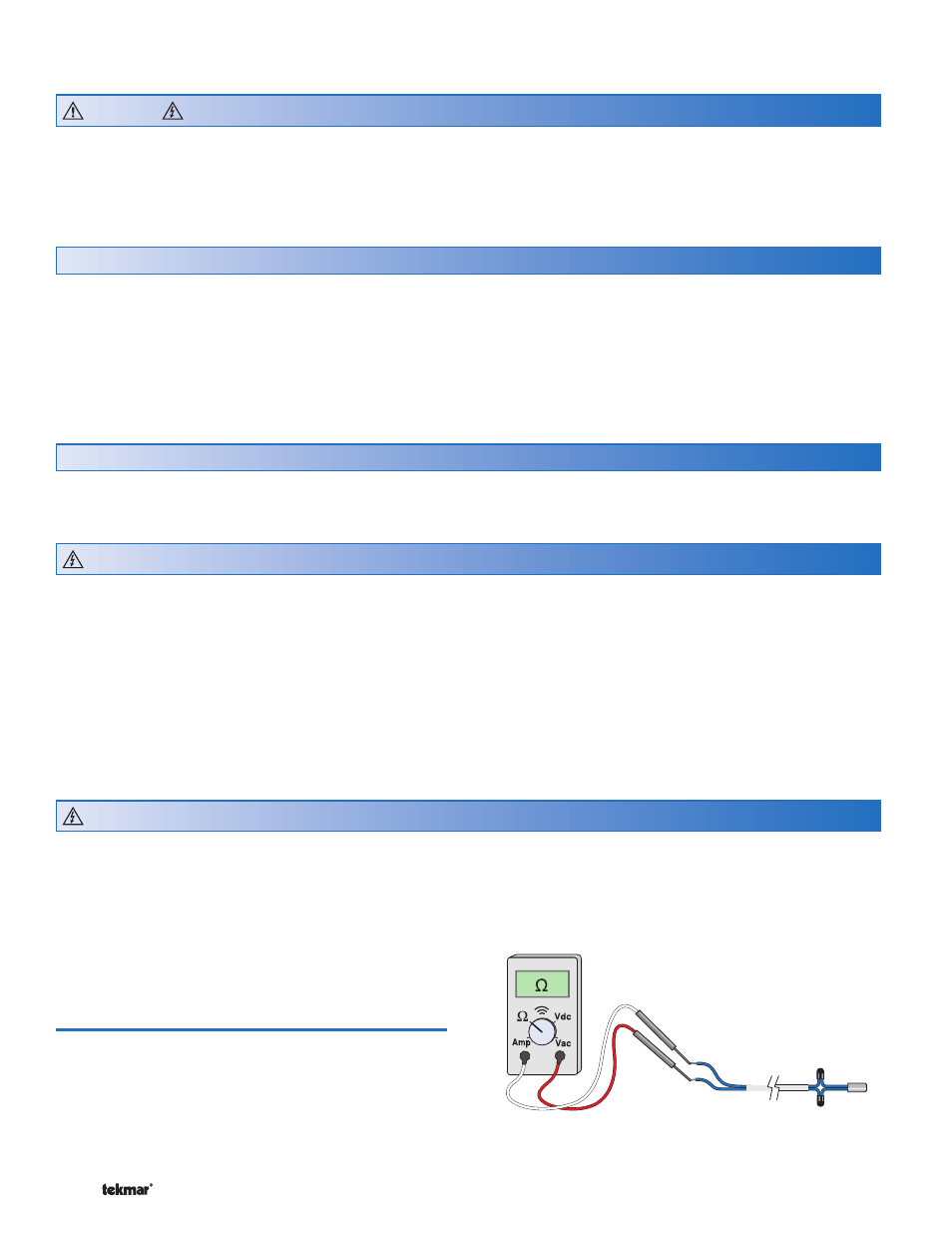

Step Four — Testing the Wiring

The following tests are to be performed using standard

testing practices and procedures, and should only be

carried out by properly trained and experienced persons.

A good quality electrical test meter, capable of reading from

at least 0 - 300 V (ac) and at least 0 - 2,000,000 Ohms, is

essential to properly test the wiring and sensors.

Test the Sensors

In order to test the sensors, the actual temperature at

each sensor location must be measured. A good quality

digital thermometer with a surface temperature probe is

recommended for ease of use and accuracy. Where a

digital thermometer is not available, a spare sensor can be

strapped alongside the one to be tested, and the readings

compared. Test the sensors according to the instructions

in the Data Brochures D 085 and D 070.

No wires should be connected to the control during testing.