Sequence of operation – tekmar 157 Difference Setpoint Control User Manual

Page 4

©

2010 D

157

-

06/10

4

of

16

Sequence of Operation

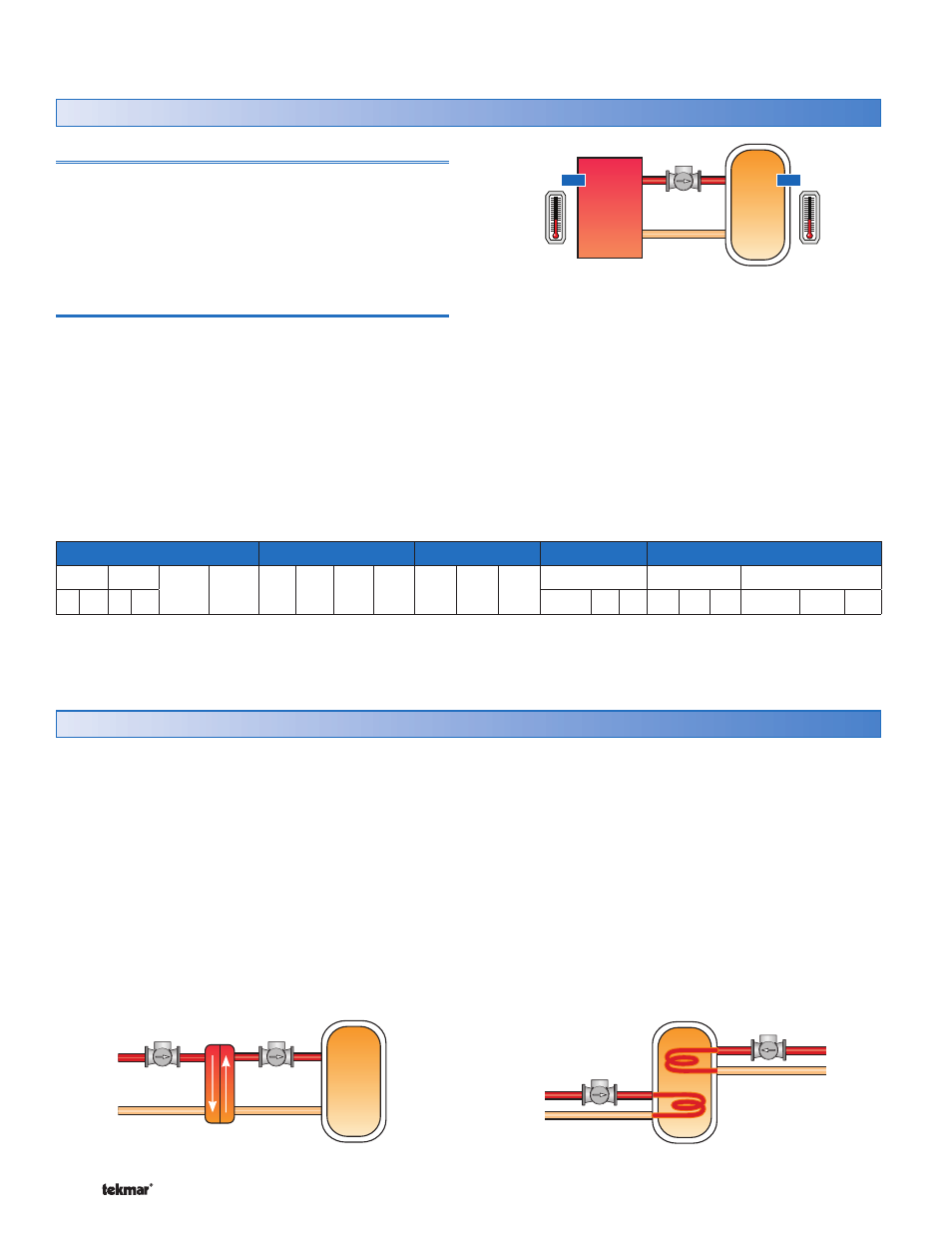

Section A – General

Powering Up The Control

When the Difference Setpoint Control 157 is powered up,

all segments are displayed in the LCD for 2 seconds, and

then the type number is displayed for 2 seconds. Next,

the software version is displayed for 2 seconds. Finally,

the control enters into the normal operating mode and by

default the LCD displays the current ΔT temperature.

Variable Speed Pump

A manufacturer approved wet rotor circulator is connected to

the 157 at the back of the control (see Table 1 for approved

pumps). The 157 increases or decreases the power output

to the circulator to vary the speed and maintain the target

difference setpoint temperature (ΔT) between the source

and the storage sensors. As the ΔT increases, the pump

speed increases and as the ΔT decreases, the pump speed

decreases. The current % output of the variable speed

pump is displayed in the view menu.

Heat

Source

Heat

Storage

Pump

Storage

Sensor

Source

Sensor

Turn On

When the variable speed pump turns on, it will operate

at 100% output for an adjustable amount of time before

operating at a variable speed starting at the minimum

pump speed setting.

Turn Off

If the temperature difference falls below the ΔT target less

the ΔT differential, or below 1°F (0.5°C), the variable

speed pump will operate at the minimum pump speed for

2 minutes before shutting off. The minimum off time for the

variable speed pump is fixed at 2 minutes.

Table 1: Manufacturer approved pump models

Grundfos (F)

Taco

B & G

Armstrong

Wilo

15-42 15-58 26-64 43-75 003 007 0010 0012 NRF

9

NRF

22

NRF

33

Astro

Star S16FX

Star

** *** ** ***

25BU 30 50

*

**

*** S21FX 17FX 30F

*Speed 1,**Speed 2, ***Speed 3

These circulators have been tested and approved by the manufacturer for use with tekmar variable speed electronics.

The 157 has a second 120 V (ac) powered output wired

through the back of the control for an on/off pump. The

second pump has 4 adjustable modes of operation

depending on the application.

Mode Off

is for applications where the second pump is

not used. The second pump relay is non-operational. Refer

to application A157-1.

Mode 1 Heat Exchanger

is for applications where the

heat exchanger pump is needed to transfer heat between

an external heat exchanger and the storage tank. The heat

exchanger pump relay will operate whenever the variable

speed pump is above 0% output. Refer to application

A157-2.

Heat

Storage

Variable

Speed Pump

Heat Exchanger

Pump

Mode 2 Heat Supplement

is for applications where the

heat supplement pump transfers heat from a supplemental

heat source (i.e. back-up boiler) to maintain the storage tank

above the minimum storage target. The auxiliary sensor is

optional in this mode. Install the auxiliary sensor in the upper

portion of the storage tank. Refer to application A157-3.

If the boiler is not flow activated, the heat supplement pump

output could provide a heat demand to another controller

to turn on the boiler.

In this mode, the minimum on and off time for the heat

supplement pump is fixed at 30 seconds.

Heat

Storage

Variable

Speed Pump

Supplemental

Heat Pump

Section B – Modes of Operation