Aileron servo installation – E-flite Twist 3D 480 ARF User Manual

Page 5

5

E-flite Twist 3D 480 ARF Assembly Manual

During the course of building your model, we

suggest you use a soft base for the building surface.

Such things as a foam stand, large piece of

bedding foam or a thick bath towel will work well

and help protect the model from damage during

assembly. This is not shown in the instructions

to provide the greatest detail in the photos.

When referencing directions (up, down, left,

right top and bottom), these directions are in

relationship to the pilot sitting in the cockpit

of the aircraft, unless noted otherwise.

Before starting the assembly of your model, we

recommend preparing your radio system for

installation. This includes charging the transmitter and

receiver batteries, as well as centering the trims and

sticks on your transmitter. If using a computer radio,

make sure to reset a model memory and name it for

this particular model. We also recommend binding

the transmitter and receiver at this time, following

the instructions provided with your radio system.

We highly recommend re-binding the radio

system once all the control throws are set. This will

keep the servos from moving to their endpoints

until the transmitter and receiver connect.

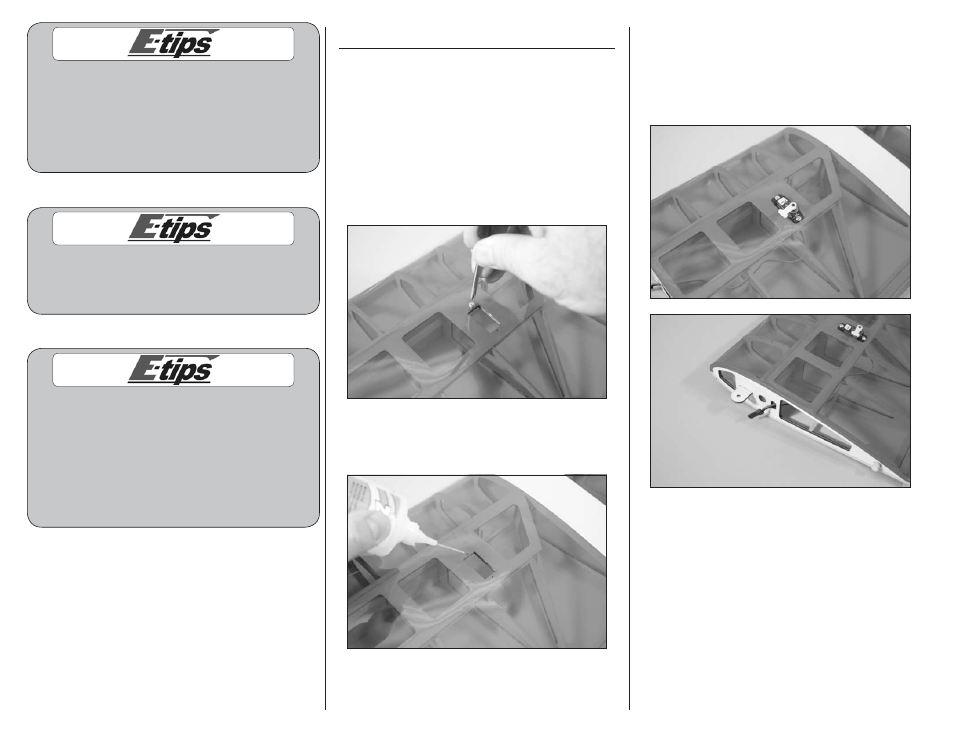

Aileron Servo Installation

Required parts

Wing panel (right and left)

Servo with hardware (2)

Required Tools and Adhesives

Thin CA

Phillips screwdriver: #1

1. Use a #1 Phillips screwdriver to thread a

servo mounting screw into each of the holes to

cut threads in the surrounding wood. Remove the

screw before moving to the next step.

2. Apply 1–2 drops of thin CA in each of the holes

to harden the surrounding wood. This will prevent

the screws from stripping surrounding wood.

3. Insert the servo lead into the wing. Hold the

wing with the tip in the air and guide the lead out

of the wing at the wing root. Secure the servo in

the wing using the screws provided with the servo

and a #1 Phillips screwdriver. The output shaft of

the servo faces toward the aileron as shown.

4. Repeat steps 1 through 3 to install the remaining

aileron servo.