E-flite Twist 3D 480 ARF User Manual

Page 18

18

E-flite Twist 3D 480 ARF Assembly Manual

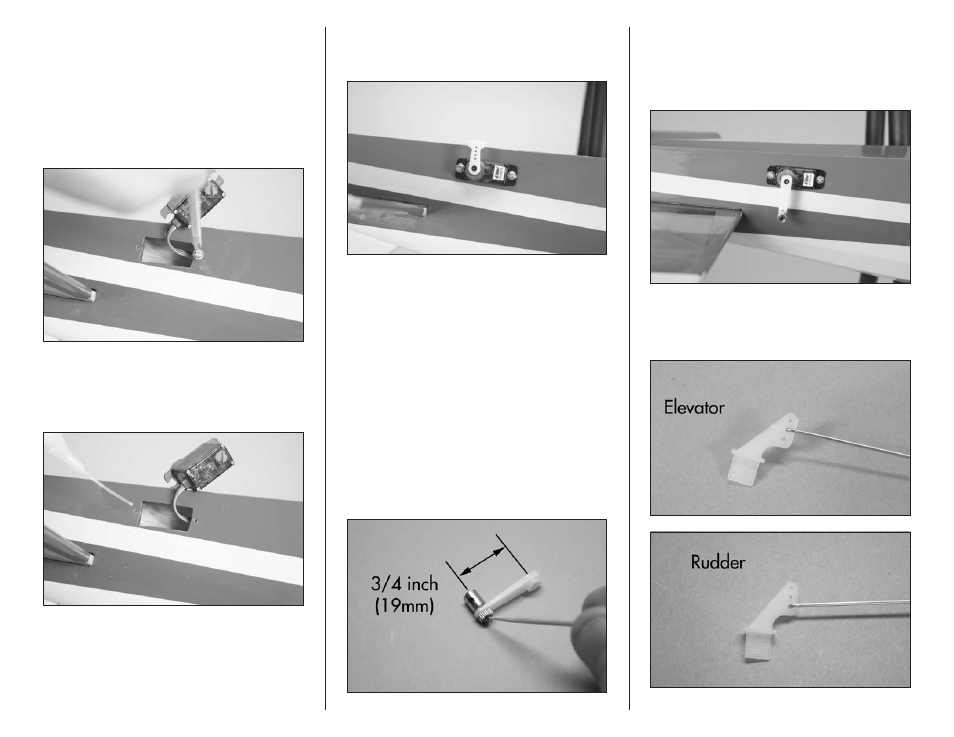

2. Fit the servo in the opening on the left side of

the fuselage for the elevator with the output shaft

facing the rear of the fuselage. Guide the lead

into the fuselage toward the receiver. Plug the lead

into the elevator port of the receiver. Use a #1

Phillips screwdriver to thread a servo mounting

screw into each of the holes to cut threads in

the surrounding wood. Remove the screw before

moving to the next step.

3. Apply 1–2 drops of thin CA in each of the holes

to harden the surrounding wood. This will harden

the threads so the screws do not easily strip the

surrounding wood.

4. Secure the elevator servo in the fuselage using

the screws provided with the servo and a #1

Phillips screwdriver.

5. Use a pin vise and 5/64-inch (2mm) drill bit

to enlarge the hole in the arm that is 3/4 inch

(19mm) from the center of the arm. Attach the

pushrod connector to servo arm. The included

washers may be used to reduce the amount of play

in the connector when it is installed. Tighten the nut

so that it is secure on the arm, but is not too tight.

There should be a small amount of play between

the arm and the connector, and the connector

should be able to rotate freely on the arm. Use a

very small amount of medium CA on a toothpick

to secure the nut to the bottom of the connector

threads. Do not use thin CA for this step as it can

wick through the nut and glue the connector to the

arm. Make sure the connector still rotates freely in

the arm after the glue is cured.

6. Remove the attached servo horn from the servo

using a #0 Phillips screwdriver. Attach the servo

arm prepared in step 7 on the elevator servos

using the screw removed from the servos and a #0

Phillips screwdriver.

7. Pass the Z-bend in the elevator pushrod through

the center hole (inner hole for the rudder) of the

control horn.