E-flite Twist 3D 480 ARF User Manual

Page 16

16

E-flite Twist 3D 480 ARF Assembly Manual

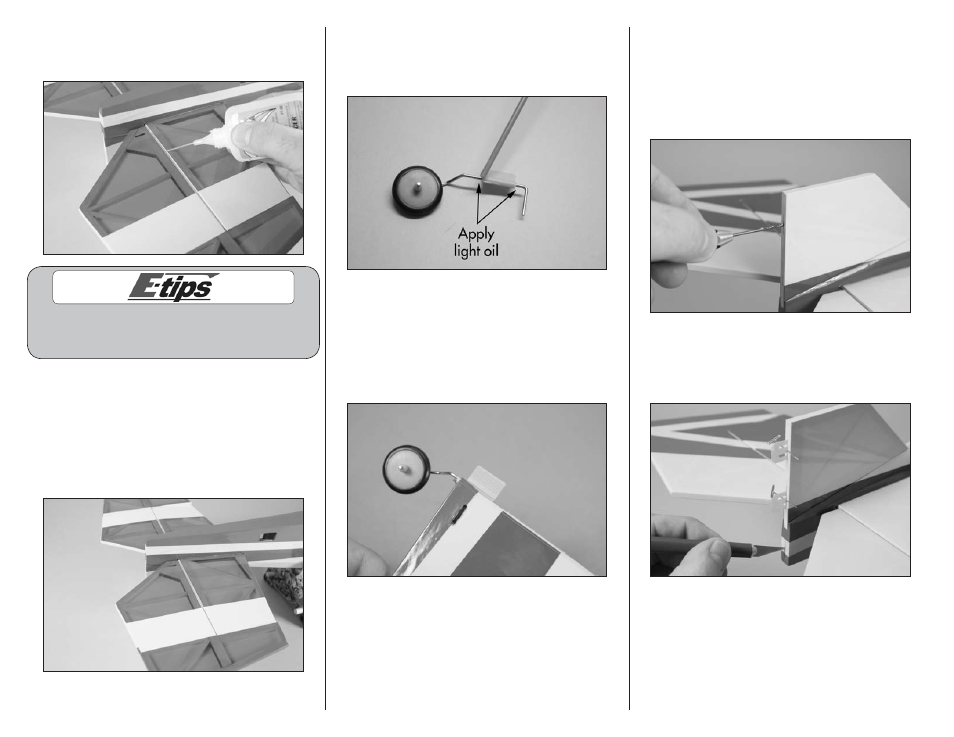

6. Saturate each of the hinges with thin CA on both

the top and bottom of the hinge. Set the assembly

aside to cure.

Do not use CA accelerator when gluing the hinges.

The CA must be allowed to soak into the hinge for the

best bond between the hinge and surrounding wood.

7. Once the CA and epoxy has cured, check

that all the hinges are secure by gently trying to

separate the elevators from the stabilizer. If any

hinges are loose, re-apply CA to the loose hinges.

Break in the hinges by working the stabilizer up

and down a number of times. This will reduce

the initial load on the servo when the servo is

connected for the first time.

8. Place a drop of light machine oil so it wicks into

the hinge knuckle along the tail gear wire. This

will keep the epoxy from entering the knuckle and

gluing the wire inside of it.

9. Fit the tail wheel assembly into the slot at the

bottom of the rudder. The bushing will rest in fully

in the slot. If not, use a hobby knife and #11 blade

to trim the slot until the knuckle fits. Once fit, lightly

sand the wire where it enters the rudder. Use a

small amount of 5-minute epoxy to glue the tail

wheel into position in the rudder.

10. Use a pin vise and 1/16-inch (1.5mm) drill

bit to drill a hole in the center of each hinge

slot to create a tunnel for the CA to wick into.

This will allow the CA to penetrate the hinge,

creating a better bond between the hinge and

surrounding wood. Prepare the rudder and

vertical fin at this time.

11. Insert the hinges in the fin. The T-pin will rest

flat on the trailing edge of the fin. Use a hobby

knife to remove the covering from the slot at the

bottom of the fuselage for the tail wheel bearing.