Rudder and elevator servo installation – E-flite Twist 3D 480 ARF User Manual

Page 17

17

E-flite Twist 3D 480 ARF Assembly Manual

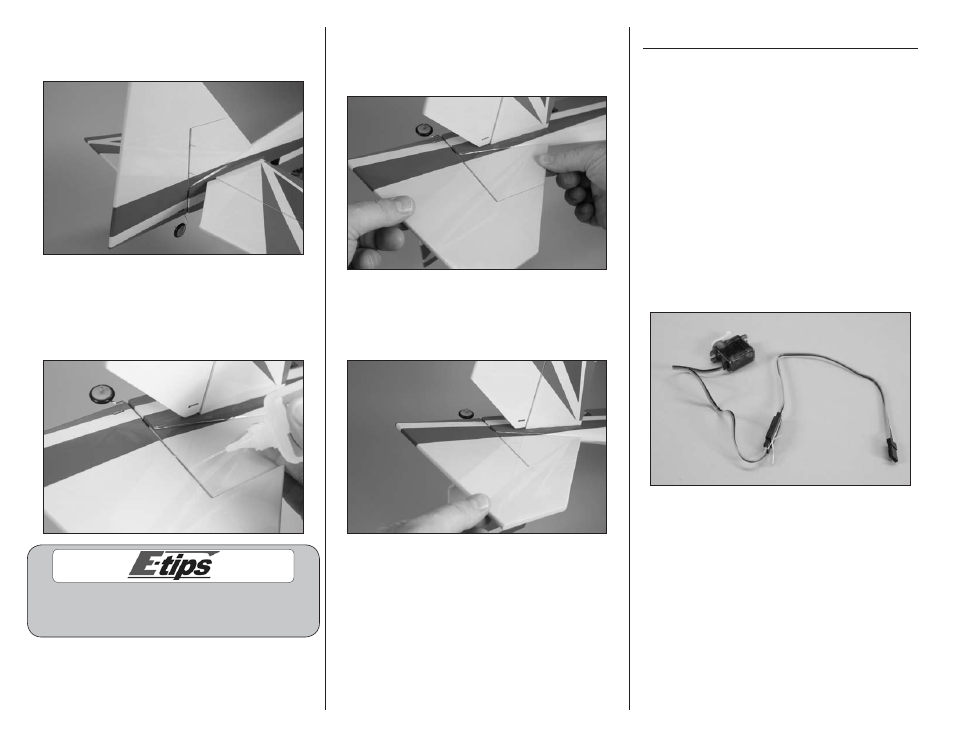

12. Slide the rudder into position, guiding the tab

on the tail wheel knuckle into the slot at the bottom

of the rudder.

13. Check to make sure the counterbalance can

move freely without hitting the top of the fin.

Remove the t-pins from the hinges and apply

thin CA to each of the hinges. Make sure to fully

saturate both sides of the hinges.

Do not use CA accelerator when gluing the hinges.

The CA must be allowed to soak into the hinge for the

best bond between the hinge and surrounding wood.

14. Once the CA has cured, gently pull on the

control surfaces and fin to make sure the hinges

are glued securely. If not, apply CA to those hinges

that are not glued and recheck.

15. Move the rudder through its range of motion

a number of times to break in the hinges. This will

reduce the initial load on the servo when the servo

is connected for the first time.

Rudder and Elevator Servo Installation

Required parts

Fuselage

Servo with hardware (2)

Flight battery

Pushrod connector (2)

Transmitter

9-inch (228mm) servo extension (2)

Nylon control horn with backplate (2)

2.0mm x 170mm pushrod with Z-bend (2)

Required Tools and Adhesives

Medium CA

Thin CA

Side cutters

String or dental floss

Hex wrench: 1.5mm

Pin vise

Phillips screwdriver: #0, #1

Drill bit: 5/64-inch (2mm)

1. Use string or dental floss to secure a 9-inch

(228mm) servo extension to one of the servos.