Overview – Banner EZ-ARRAY USB Serial Adapter User Manual

Page 8

6

P/N 130426 Rev. C

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

A-GAGE EZ-ARRAY

Instruction Manual

Overview

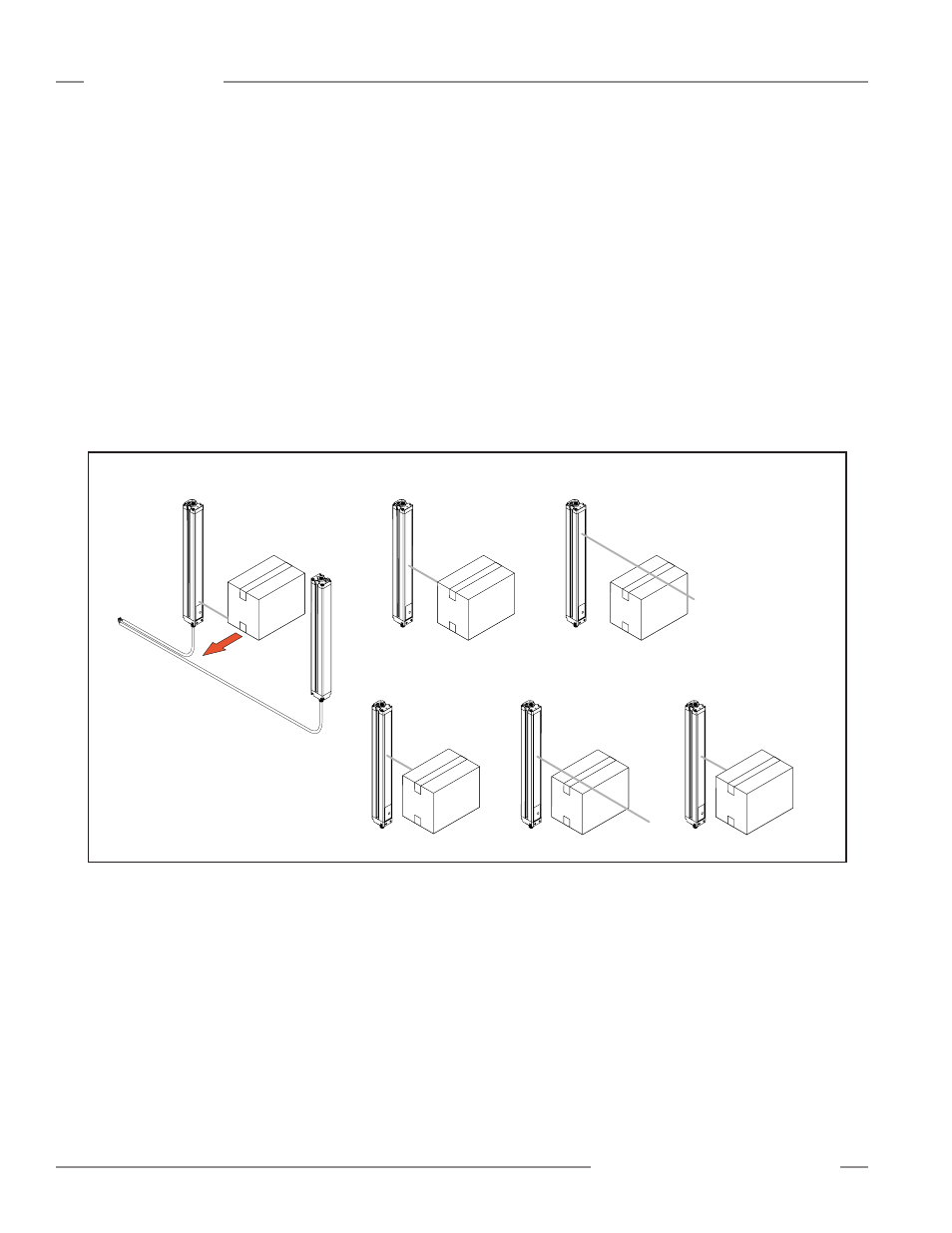

Double-Edge Scan is used to detect two edges of a single

object, for example, to determine box width measurements.

Double-edge scan requires the selection of a step size: 1, 2,

4, 8, 16 or 32 beams. The sensor uses the steps to “skip” over

beams, as follows:

1. The sensor activates beam 1 (closest to the sensor display end).

2. The sensor activates the next beam, determined by the step

size. (For example, if the step size is 2, beam 3 is next; if the

step size is 8, beam 9 is next.)

3. As long as the activated beam is made (unblocked), the sensor

continues the stepping routine until a blocked beam is found.

4. When a blocked beam is found, a binary search is conducted

to find the object’s “bottom” edge.

5. When the bottom edge is found, the sensor continues to step

through the array until it finds the next unblocked beam.

6. Another binary search is performed to find the second edge.

Similar to single-edge scan, double-edge scan has some

restrictions: the object should provide a solid obstruction; the size

of the object determines the maximum step size (Figure

1-6). Double-edge scan can be used to detect up to three

objects. Like single-edge scan, double-edge scan works only

when the high-excess-gain setting is selected. When double-

edge scan is selected, the sensor object detection size varies,

depending on the step size, but edge resolution is 2.5 mm.

Figure 1-7. Finding an edge using a binary search (single-edge scan)

Emitter

Receiver

Step #1

Step #2

Step #3

Step #4

Step #5

Beam #1 of 30

blocked

Beam #15

blocked

Beam #23 clear

Beam #19 clear

Beam #17

blocked

Step #6

Beam #18

blocked