2 control module mounting, Installation and mechanical alignment – Banner A-GAGE MINI-ARRAY Series User Manual

Page 15

Installation and Mechanical Alignment

15

Banner Engineering Corp. • Minneapolis, U.S.A.

Website: http://www.baneng.com • Tel: 888.373.6767

Mount the emitter and receiver in their brackets and position the red lenses of the two

units so they directly face each other. The connector ends of both sensors must point

in the same direction. Measure from one or more reference planes (e.g. the building

floor) to the same point(s) on the emitter and receiver to verify their mechanical

alignment. If the sensors are positioned exactly vertical or horizontal to the floor, a

carpenter’s level is useful for checking alignment. A straightedge or a string extended

between the sensors also helps with positioning. Also check “by eye” for line-of-sight

alignment. Make any necessary final mechanical adjustments, and hand-tighten the

bracket hardware. See Section 4.2 for further information on alignment.

3.2 Control Module Mounting

The control module must be installed inside an enclosure which has a NEMA (or IEC)

rating suitable for the operating environment.

Mounting dimensions for the controller are shown in Figure 2-2, on page 11

.

The

control module is supplied with M3.5 hardware for direct mounting to a surface, or it

may mount directly onto standard 35 mm DIN rail.

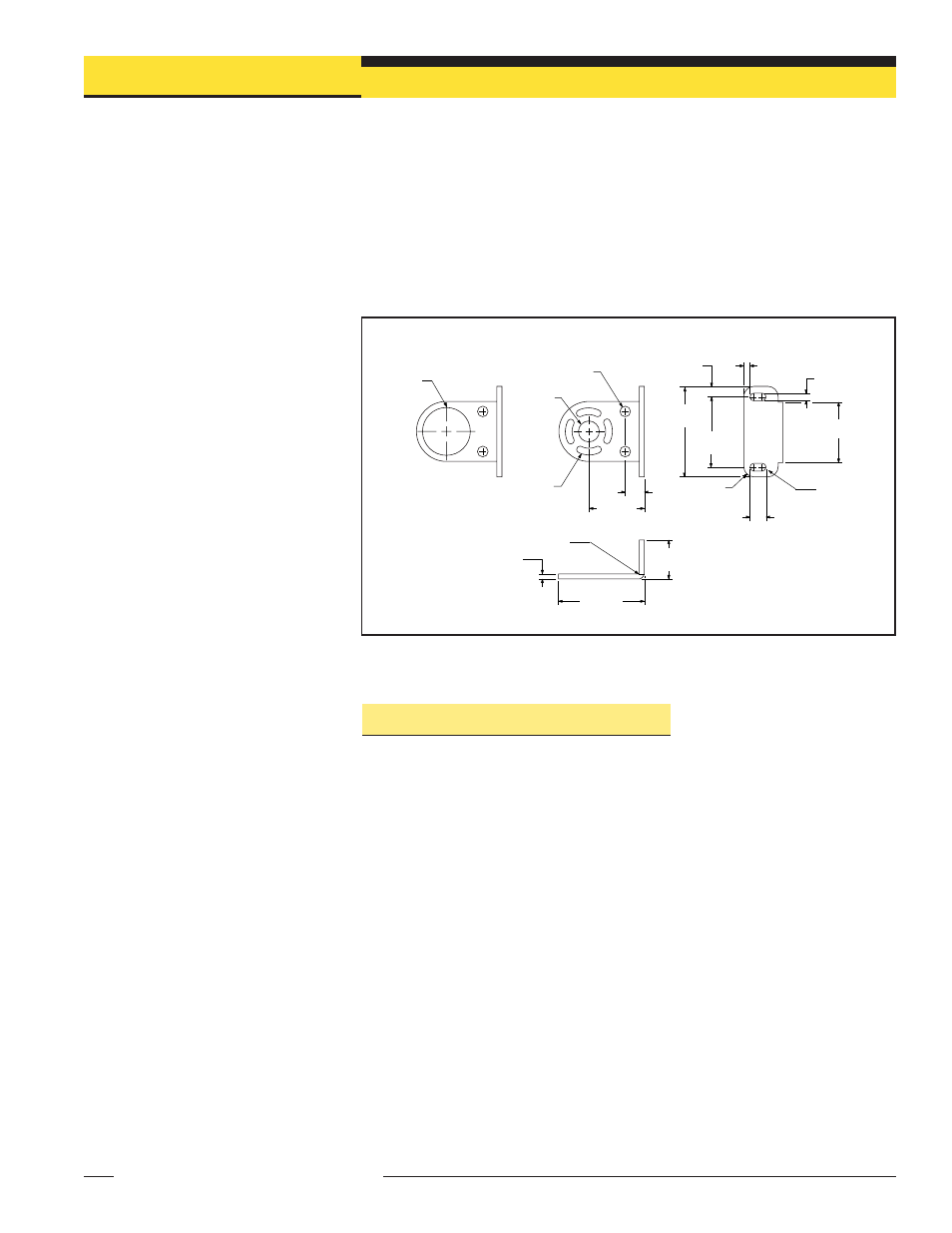

NON-QD End

QD End

Min. R.

Full R (4)

4.8 mm (2)

(0.19")

38.1 mm

(1.50")

6.4 mm R

(0.25")

44.5 mm

(1.75")

6.4 mm

(0.25")

57.2 mm

(2.25")

3.8 mm

(0.15")

10.2 mm (2)

(0.40")

ø30.5 mm

(1.20")

34.8 mm

(1.37")

11.9 mm

(0.47")

Slots have clearance

for M4 bolts (supplied)

and allow ±30° rotation

ø13.2 mm

(0.52")

ø6.8 mm (2)

(0.27")

3.0 mm

(0.12")

24.6 mm

(0.97")

53.8 mm

(2.12")

Material: Cold Rolled Steel

Finish: Black, Zinc Plated

Chromate Dip

Figure 3-2. A-GAGE MINI-ARRAY emitter and receiver mounting bracket dimensions