5 error messages, troubleshooting, 1 troubleshooting – Metrohm 756 KF Coulometer User Manual

Page 111

5.1

Troubleshooting

756/831 KF Coulometer, Instructions of Use

103

5 Error messages, troubleshooting

5.1 Troubleshooting

The determination of the free water is easily done as far as the specifications of the

reagent manufacturer regarding the "water capacity" of the reagents are concerned.

Problems may occur with specific sample matrices. The relevant literature contains many

precise analysis instructions. In the following table we attempt to show you solutions

concerned more with the instrument.

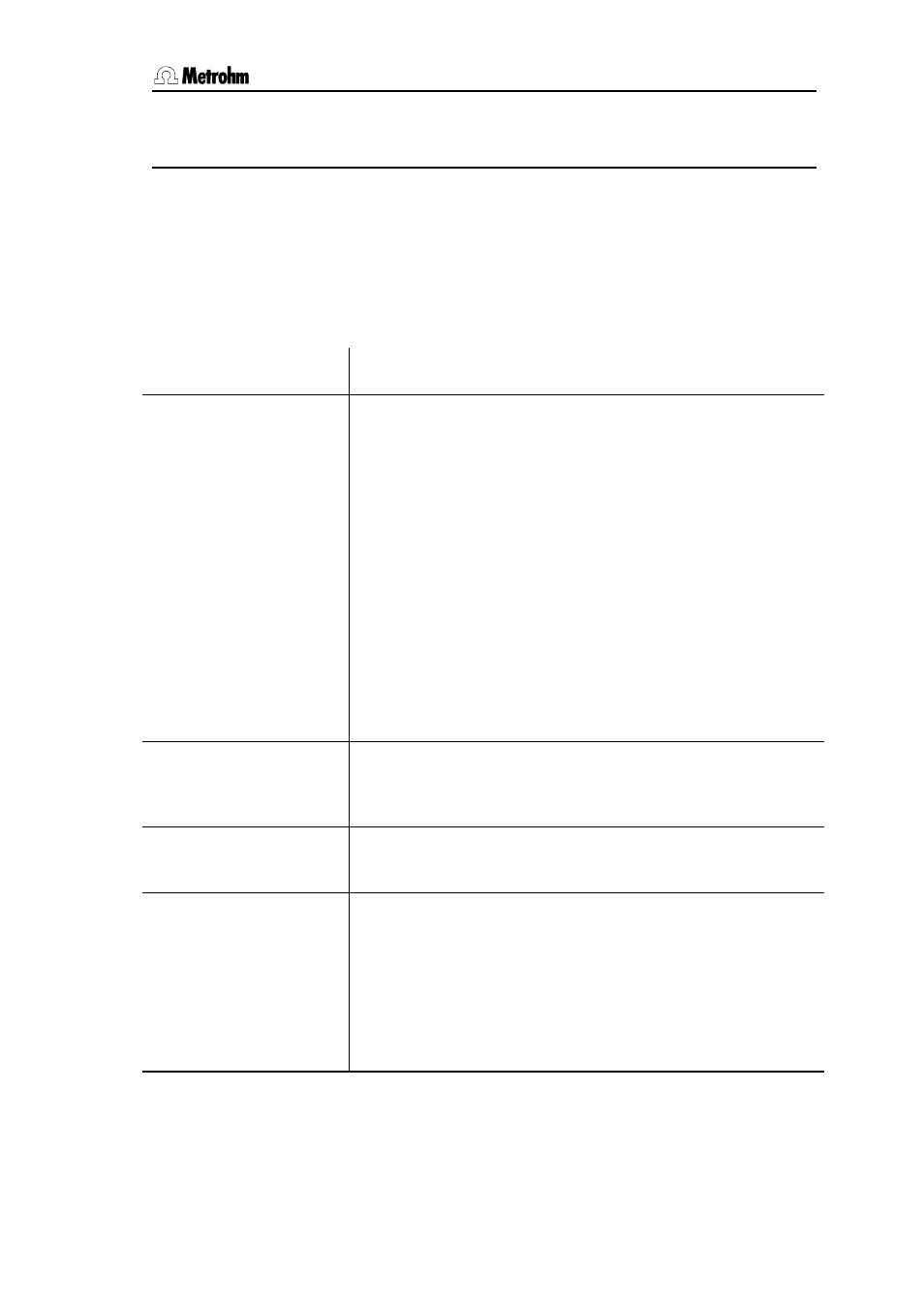

Problem

Possible causes and remedies

Drift too high

•

Depots containing water in the titration vessel: Shake

titration vessel.

•

Reagent exhausted or contaminated ⇒ exchange.

•

Moisture penetrating into titration vessel:

. molecular sieve exhausted?

. septum pierced?

. seals not OK?

. ground joint sleeves not smooth?

•

Generator electrode diaphragm polluted or moist.

•

Sample matrix consumes iodine. Change reagent more

often.

•

When working with Oven/Oven Sample Processor:

. molecular sieve of Oven/Oven Sample Processor

exhausted?

. gas flow too high?

. allow to run overnight.

. screw seals tight?

Drift unstable

•

Poor stirring: Stir so that mixing is efficient, but without the

formation of air bubbles.

•

Reset the control parameters to standard values.

Oven parameters wrong

in Coulometer report

Switch off the report output at the oven.

Result too high

•

Titration vessel not properly conditioned: Shake and wait

until drift has stabilized.

•

With the generator electrode without diaphragm: Set

generator current to 400 mA, see also page 33.

•

Sample contains substances which can be oxidized.

•

Set stop drift higher.

•

Drift correction too small, e.g. with unstable drift or with

manual drift correction.