Installation / assembly – Bendix Commercial Vehicle Systems EB/ES BRAKES SERVICE MANUAL User Manual

Page 52

51

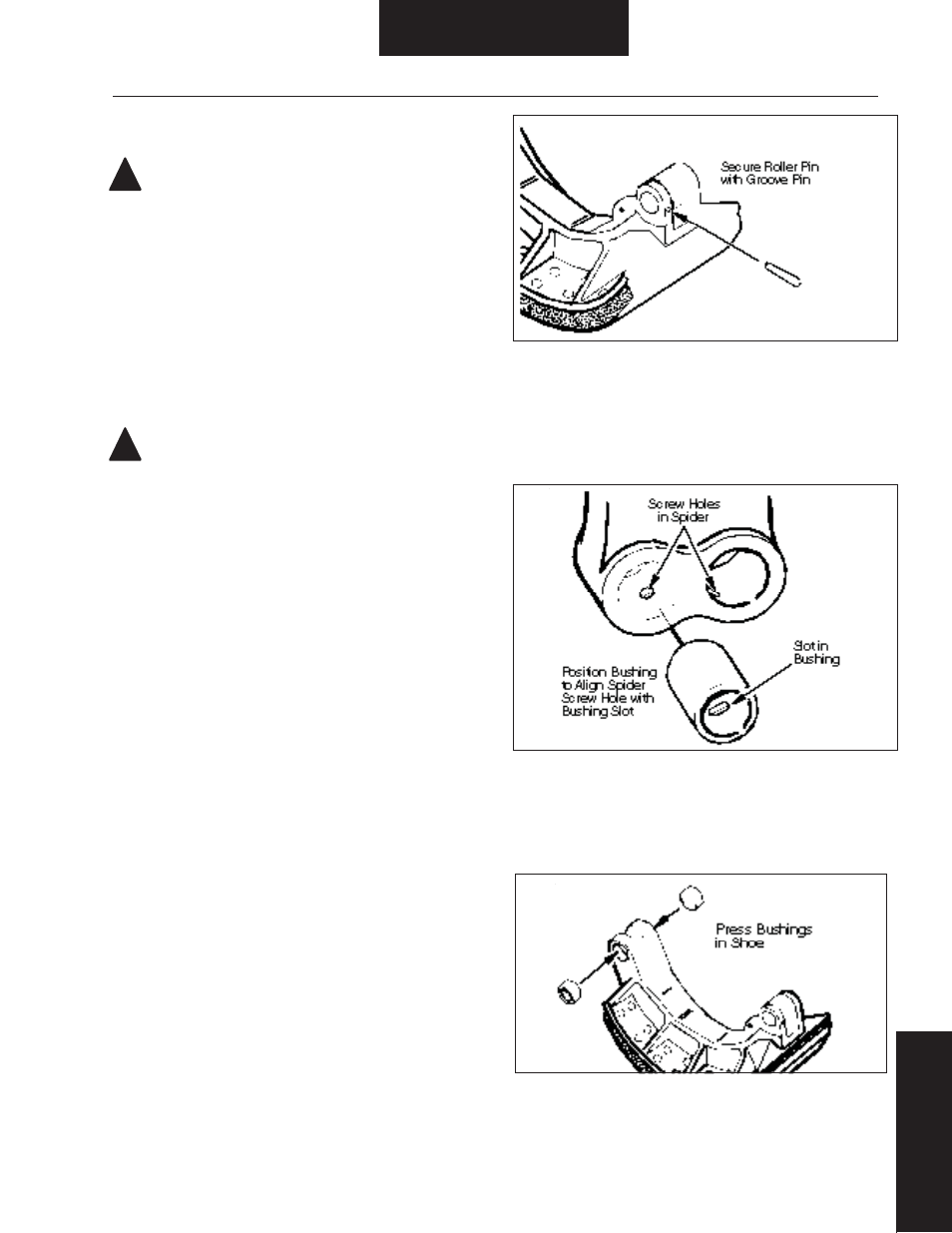

Figure 75. Groove Pin Installation

Figure 76. Spider Anchor Pin Bushing Installation

!

!

Figure 77. Shoe Anchor Pin Bushing Installation

Shoe Installation

Installation / Assembly

ES-165-7-H Severe Duty Brake

WARNING: The long term effects of non-asbestos fi bers,

have not been determined. Therefore, precautions should be

used when handling these materials.

See General Information/lining Material Warning

1. See Inspection & Repair / Replacement to verify that spider,

camshaft, bracket, and brake adjuster are serviceable and properly

installed.

2. During shoe installation, lubricate:

• Roller inside diameter.

• Anchor pin - light fi lm of grease.

CAUTION: Use only grease conforming to NLGI grade #1,

high-temperature, waterproof.

Do Not Lubricate:

• Cam head surface. For effi cient operation, this surface must

remain free of oil, grease or other contaminants.

NOTE: If rollers were removed, replace with new Bendix OEM rollers

and pins.

3. Lubricate roller inside diameter (see Step 2), prior to installa-

tion. Assemble roller and pin to shoe and secure with groove pin.

Stake casting area around groove pin. Refer to Figure 75.

4. After driving out old anchor pin bushings from spider, see

Removal/Disassembly - Shoe Removal, press new anchor pin

bushings in spider, aligning slots in bushing with tapered holes in

spider. Refer to Figure 76.

5. Press anchor pin bushings in brake shoes. Refer to Figure 77.

6. Lubricate anchor pin prior to installation (see Step 2).

7. Place the lower shoe in position on the spider, and install lower

anchor pin, washers and retaining rings. Refer to Figure 78.