Bendix Commercial Vehicle Systems BRAKE CHAMBERS User Manual

Bendix

1

®

Bendix

®

Brake Chambers

SD-02-1302

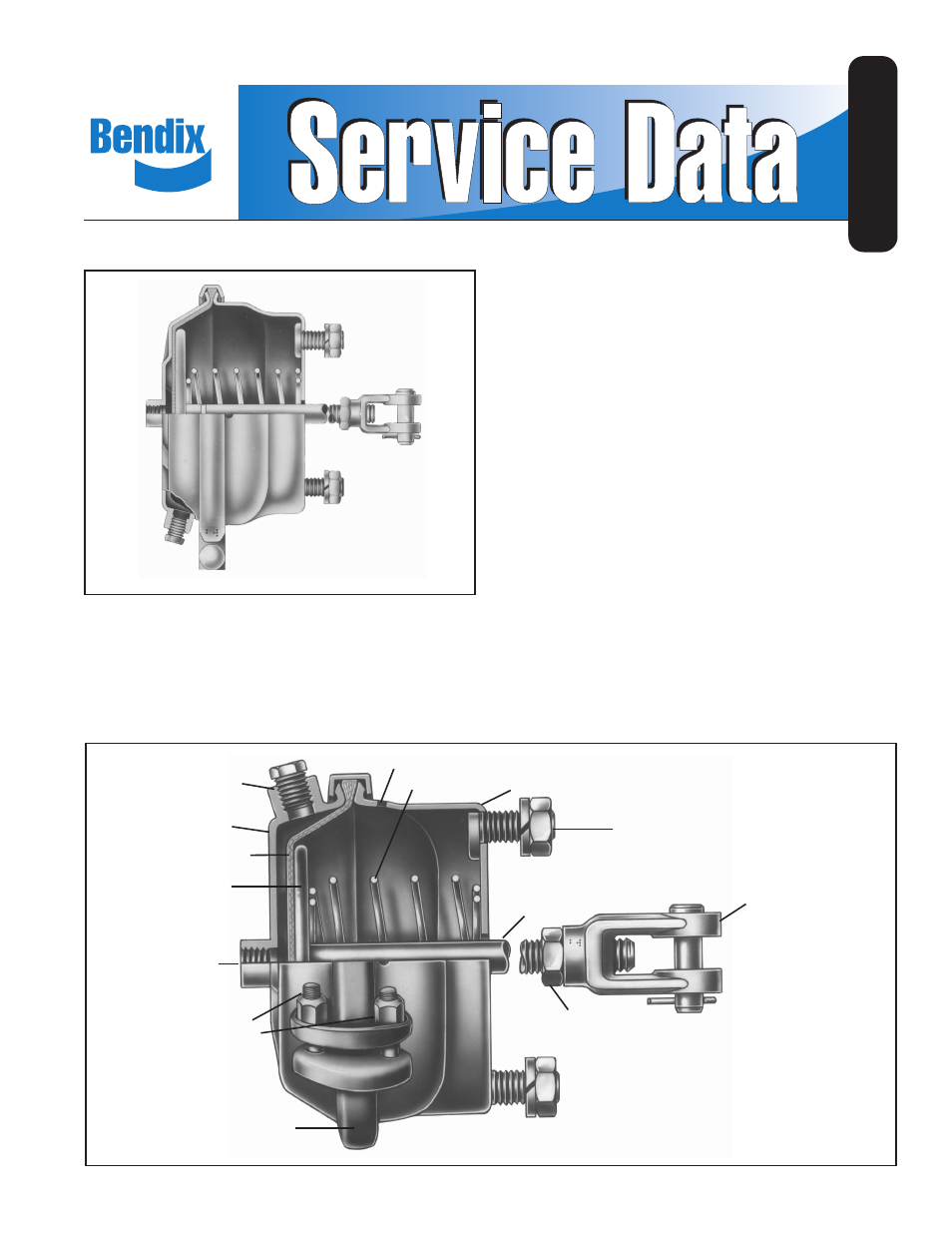

Clamp Ring (C)

Push Plate and Push

Rod Assy.

Clamp Ring Nuts

& Bolts

Center Inlet Port

Non-Pressure Plate (B)

Spring

Vent

Side Inlet Port

(shown plugged)

Pressure Plate (A)

Diaphragm

Push Plate

DESCRIPTION

The brake chamber is a diaphragm-type actuator which

converts the energy of air pressure into mechanical force.

See Figure 2. The diaphragm is held between the pressure

plate (A) and non-pressure plate (B) by either a one- or

two-piece clamp ring (C).

Different size brake chambers are identified by numbers

which specify the effective area of the diaphragm. For

example, a brake chamber that has 30 square inches of

“effective area” (the area of the diaphragm that generates

force on the push plate), is commonly referred to as a type

30 brake chamber. See Figure 2.

Since one side of a brake chamber diaphragm is exposed to

the applying air pressure and the other side to atmospheric

pressure, the chamber has a pressure and a non-pressure

side. The non-pressure plate is usually vented to

atmosphere by vent holes. Installations where the chamber

must be weather-proof, venting is accomplished through a

variety of methods. Consult the OEM for specific details.

The standard diaphragm material is a compound of natural

rubber with a fabric interior of nylon. Neoprene-nylon

diaphragms are optionally available.

OPERATION

Controlled air pressure enters the brake chamber through

the inlet port and acts upon the diaphragm moving the push

plate and rod assembly forward.

Lock Nut

Yoke

Mounting

Bolts

FIGURE 2 - CUT-AWAY VIEW

FIGURE 1 - BENDIX

®

BRAKE CHAMBER