Installation / assembly, Shoe and lining installation – Bendix Commercial Vehicle Systems EB/ES BRAKES SERVICE MANUAL User Manual

Page 46

45

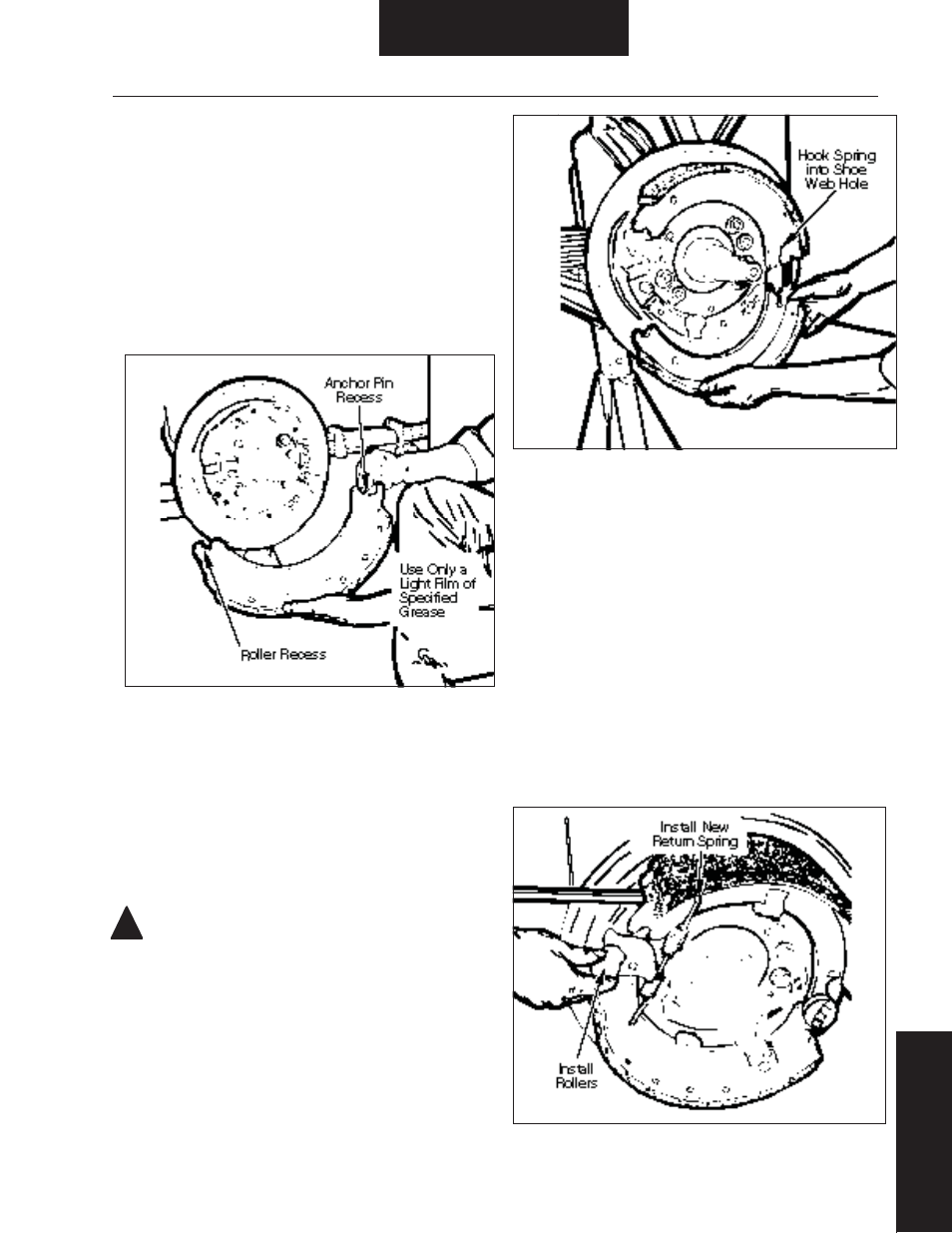

Figure 58. Shoe Retaining Spring Installation

Figure 59. Shoe Return Spring and Roller Installation

!

Installation / Assembly

Brake Adjuster/Shoe

and

Lining Installation

Shoe and Lining Installation

An index to the location of shoe installation procedures is provided

in Table 8. Locate the brake model under service to identify the

location of the appropriate shoe installation procedures.

EB/ES-150-4L Brake

1. Verify that spider, camshaft, air chamber bracket, and brake

adjuster are serviceable and properly installed.

NOTE: See General Information - Parts Nomenclature for shoe

hold-down spring variations.

2. Apply a thin fi lm of grease to cam roller and anchor pin recesses

of each shoe web. Refer to Figure 57.

CAUTION: Use only grease conforming to NLGI grade #1,

high-temperature, waterproof.

3. Position upper shoe and lining web on anchor pin and rotate

down. Continue rotation until shoe is held in place by shoe hold-

down spring.

4. Hook one end of a new shoe retaining spring into hole in upper

shoe web so coil lays across anchor pin. Refer to Figure 58.

5. Hook opposite end of spring into hole on lower shoe web.

6. Stretch spring to allow positioning of lower shoe web against

anchor pin.

7. Rotate lower shoe into position on spider.

8. Hook end of a new shoe return spring in lower shoe web hole.

Using a screwdriver for assistance, stretch shoe return spring to

hook it in upper shoe web hole. Refer to Figure 59.

9. Using a large screwdriver or lever with tip, stretch shoe return

spring to allow insertion of a new cam roller on upper shoe web.

10. Install a new cam roller on lower shoe web in same manner.

Figure 57. Shoe Web Lubrication