Installation / assembly – Bendix Commercial Vehicle Systems EB/ES BRAKES SERVICE MANUAL User Manual

Page 48

47

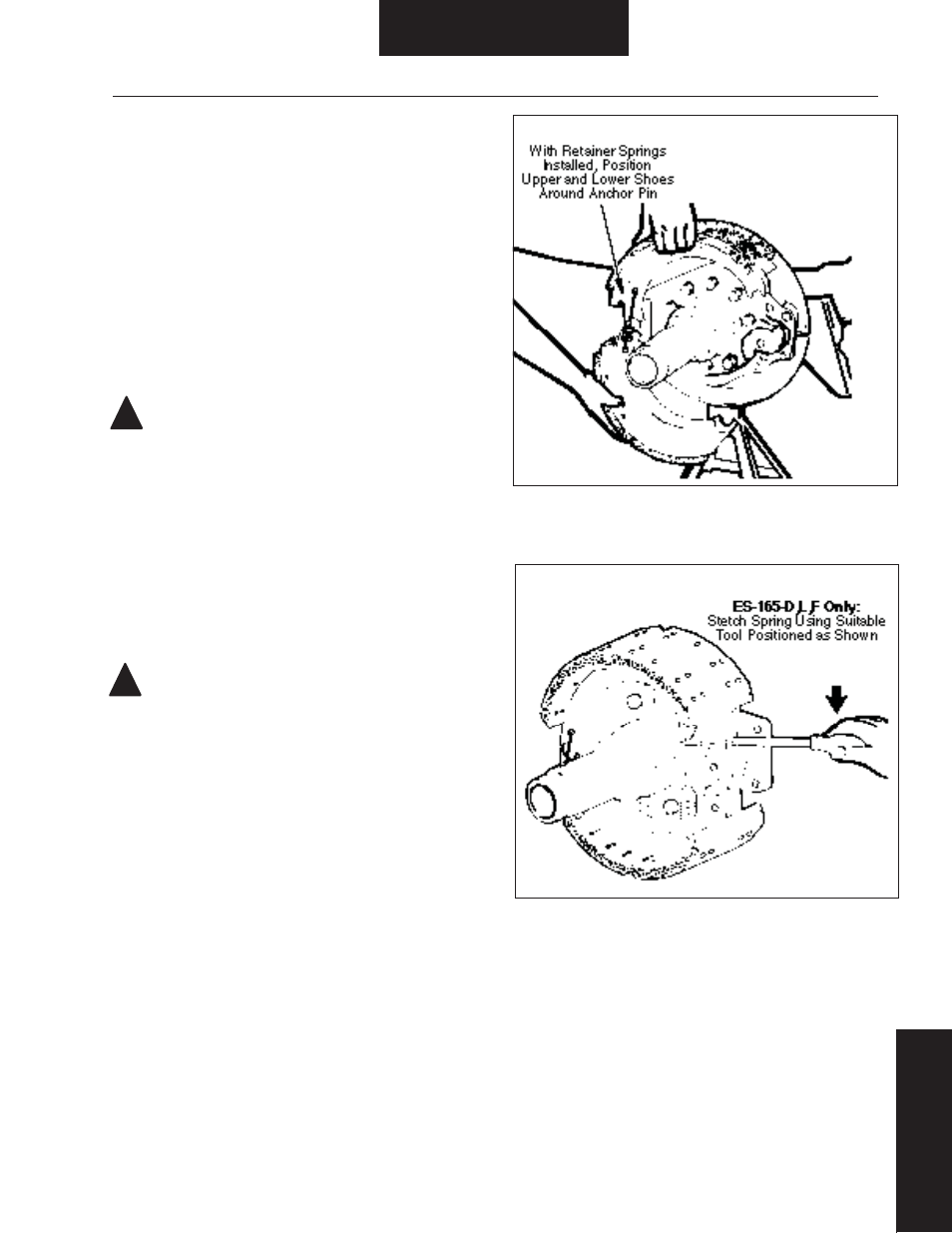

Figure 62. Upper and Lower Shoe Positioning

Figure 63. Shoe Return Spring Installation

!

!

Installation / Assembly

Shoe and Lining

Installation

All EB (except EB-150-4L) and ES-165 5/6/7/8D,F,L

NOTE: The following procedures are divided into sections,

identifi ed by brake model numbers.

1. See Inspection & Repair / Replacement to verify that spider

camshaft, bracket, and brake adjuster are serviceable and properly

installed.

2. During shoe installation, lubricate:

• Shoe roller recess - one-piece roller.

• Roller I.D. - two-piece roller.

CAUTION: Use only grease conforming to NLGI grade #1,

high-temperature, waterproof.

Do Not Lubricate:

• Cam head surface. For effi cient operation, this surface must

remain free of oil, grease or other contaminants.

3. Hook ends of new retainer springs into holes in both shoe

tables, hooks pointing out.

4. Position upper and lower shoes around anchor pin. Refer to

Figure 62.

WARNING: The long term effects of non-asbestos fi bers,

have not been determined. Therefore, precautions should be

used when handling these materials.

See General Information / Lining Material Warning

5. Install a new shoe return spring. Refer to Figure 63.

NOTE: On ES-165-D, 1, F, a lever may be required to assist in

hooking shoe return spring.