Maintenance, Motor storage, Linear encoder carriage/heat sink – Rockwell Automation LDL Ironless Linear Servo Motors User Manual

Page 19: Maintenance motor storage, Linear encoder, Carriage/heat sink

Publication LDL-UM001A-EN-P - March 2009

19

Start Chapter 2

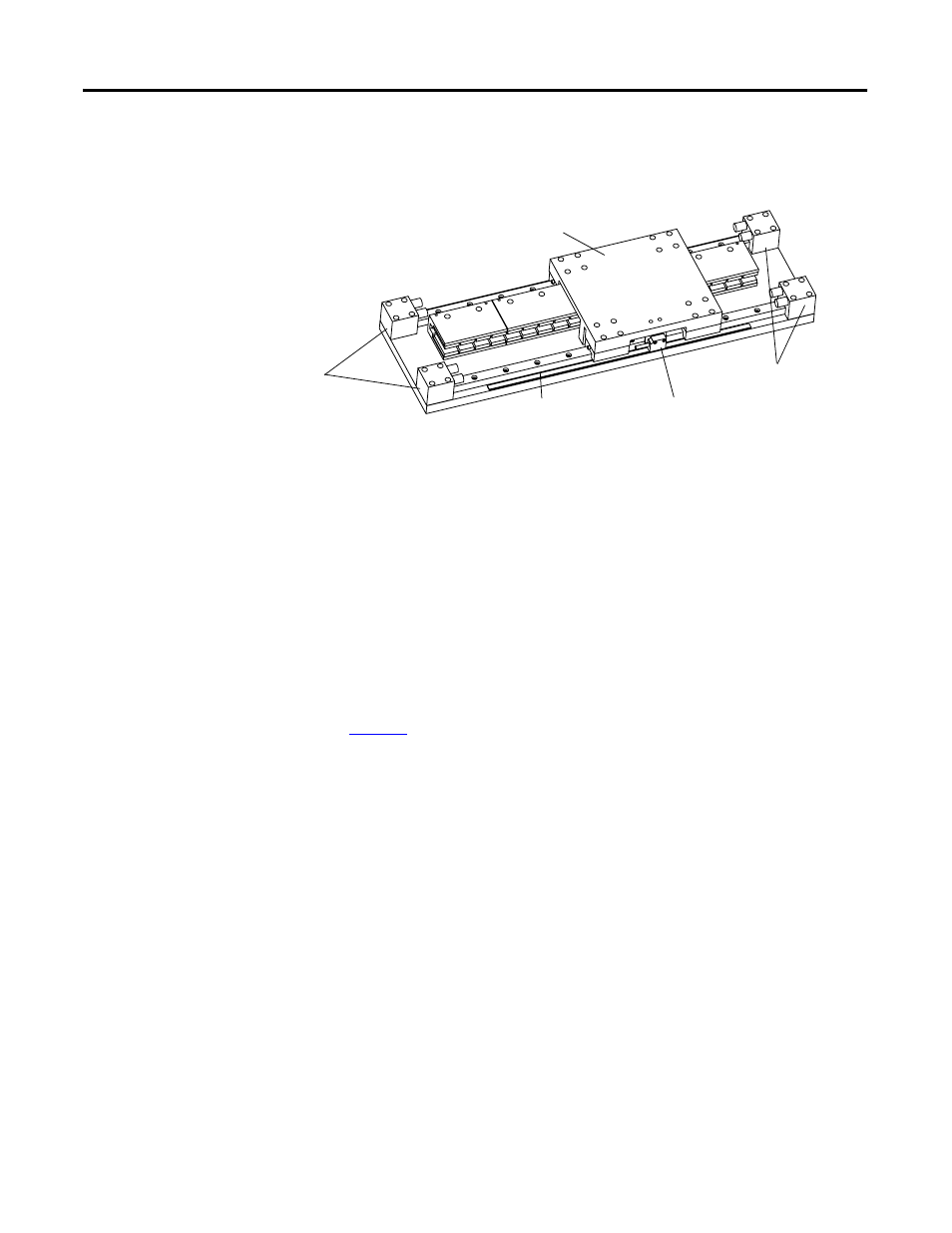

stops. The following diagram shows a minimal system with

mechanical stops.

Linear Encoder

Your linear motor components needs to be integrated with a linear

encoder purchased from a third party.

Carriage/Heat Sink

The linear motor coil requires a heat sink to maintain performance.

The heat sink requires a minimal mass and surface area as shown on

. It can as so serve as the carriage in moving coil system or be

designed into the base in moving magnet system.

Maintenance

Linear motors require no maintenance when operated in a relatively

clean environments. For operation in harsh and dirty environments,

minimal cleaning is recommended every 6 months.

Clean the metallic debris and other contaminants from the air gap. Use

a strip of masking tape to effectively remove the metal debris. Apply a

strip of tape in the magnet channel and then remove it.

Motor Storage

Motor storage area should be clean, dry, vibration free, and have a

relatively constant temperature. If a motor is stored on equipment, it

should be protected from the weather. All motor surfaces subject to

corrosion should be protected by applying a corrosion resistant

coating.

Mechanical Stops

Mechanical Stops

Encoder readhead

Encoder strip

Carriage/Heat Sink