Cable construction – Rockwell Automation 9000 Series Sensor User Manual

Page 21

Sensor Cable Guidelines

Entek 9000 Series Sensor Installation Guide

13

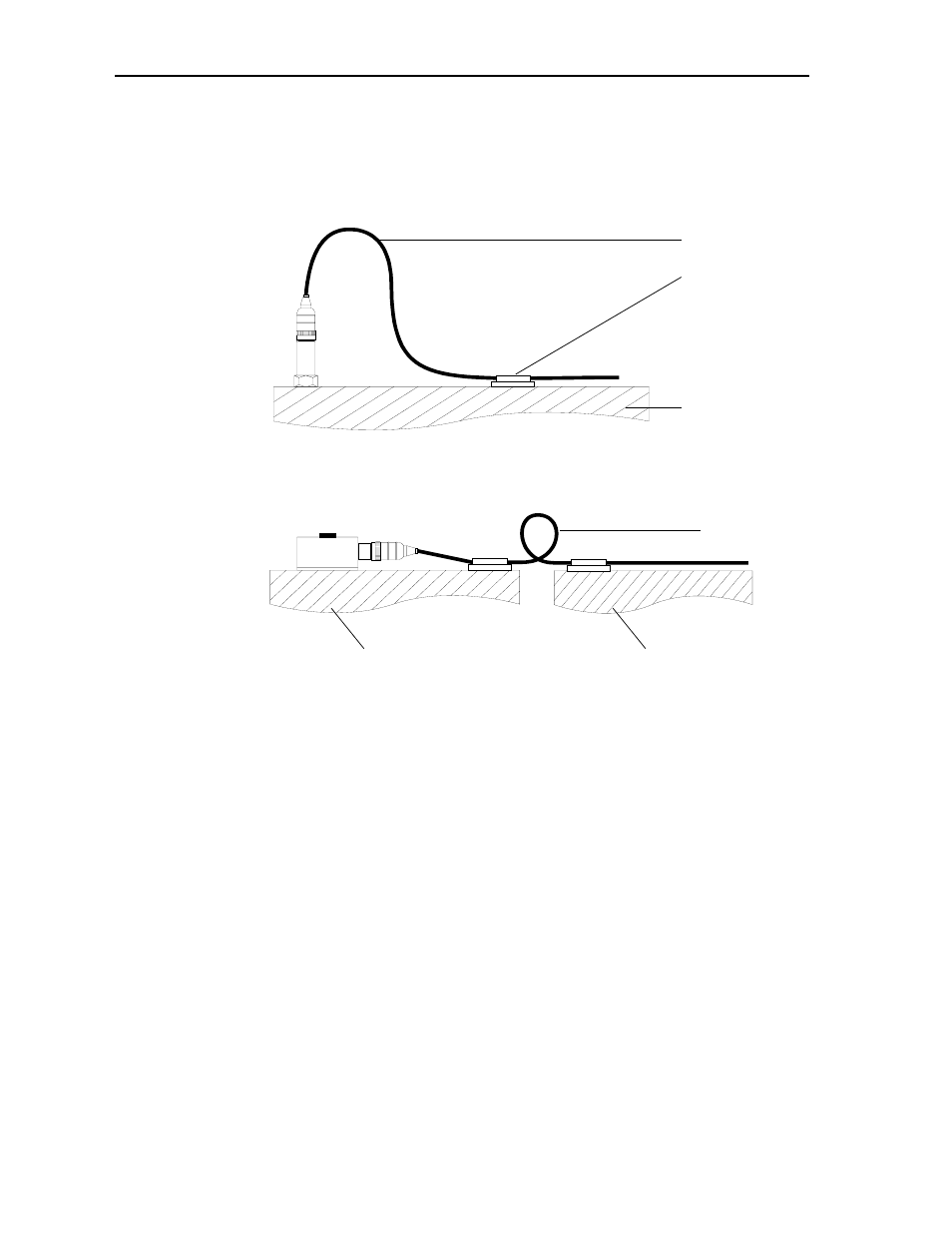

For a sensor with a top exit cable connection, make sure there is at least 6 inches of

clearance above the machine surface to allow for movement of the sensor and cable.

Clamp the cable within 6 inches of the sensor, allowing enough room for the cable to

bend without damage. Clamp the cable at intervals to prevent movement.

For sensors with a side exit cable connection, clamp the cable 3–4 inches from the

sensor. Clamp the cable at intervals to prevent movement.

Cable construction

The sensor cable should be twisted pair with its own foil shield. Do not ground the cable

shield drain wire at both ends. The shield connections should be carried through any

junction boxes without connecting to a ground or other shields.

If the end of the sensor cable is in a location where it will be splashed or hosed down, coat it

with RTV silicone rubber sealant to prevent fluids from entering the cable.

!

At the sensor end, use RTV in and around the connector and cable entry to the

connector.

!

At the opposite end to the sensor, terminate the cable in a NEMA housing using proper

cable entry connectors that create a tight seal around the cable and the entry hole of the

housing.

Machine surface

Cable clamp

Service loop

Machine surface

Fixed surface

Service loop