Mounting sensors with adhesive – Rockwell Automation 9000 Series Sensor User Manual

Page 15

Sensor Mounting

Entek 9000 Series Sensor Installation Guide

7

When connecting cables for sensors with ground-isolated cases, make sure that the cable

shield is not grounded at the sensor end. There are two possible cable configurations:

!

In coaxial cable, the center conductor carries the signal and power, while the outer braid

provides shielding and signal return. Grounding the shield at the monitoring device and

not at the sensor isolates the sensor and prevents ground loops.

!

In cable with two wires and shield, the signal and power are carried on one lead and the

signal return on the other lead. The outer braid provides shielding. To isolate the sensor

and prevent ground loops, ground the shield at the monitoring device.

Note: It is very important to properly ground the cable shield. Failing to do so can result in

interference with the signal and possible damage to the sensor in high electromagnetic

interference/electrostatic discharge environments.

Mounting sensors with adhesive

If a mounting hole cannot be drilled into the machine surface, you can mount the sensor

using adhesive. There are two ways to do this: you can mount the sensor directly to the

machine; or you can mount a flat plate with a threaded stud, and attach the sensor to the

stud. Note that mounting the sensor using adhesive may limit the detection of high

frequencies. Suggested adhesives are listed in the following table.

Note: Entek recommends following the API 670 requirements for surface finish and flatness, even

for non-API installations. If the surface is not properly prepared, it can reduce the detection

of higher frequencies.

1. Spot face the surface on the machine case or bearing housing where you want to install

the sensor. Per the requirements of API 670 Appendix C.2.1, the surface finish should

be within 0.8 micrometers (.032 mil, or 32 µinches) and the flatness should be below 25

micrometers (1 mil).

2. Prepare the surface following standard adhesive bonding practice. Abrade and then

thoroughly clean the spot on the machine with solvent.

3. Mix the adhesive according to its directions.

4. Attach the sensor or plate to the machine.

5. Allow the recommended time for the adhesive to cure.

6. Make sure the sensor is grounded through the cable shield to a good electrical ground.

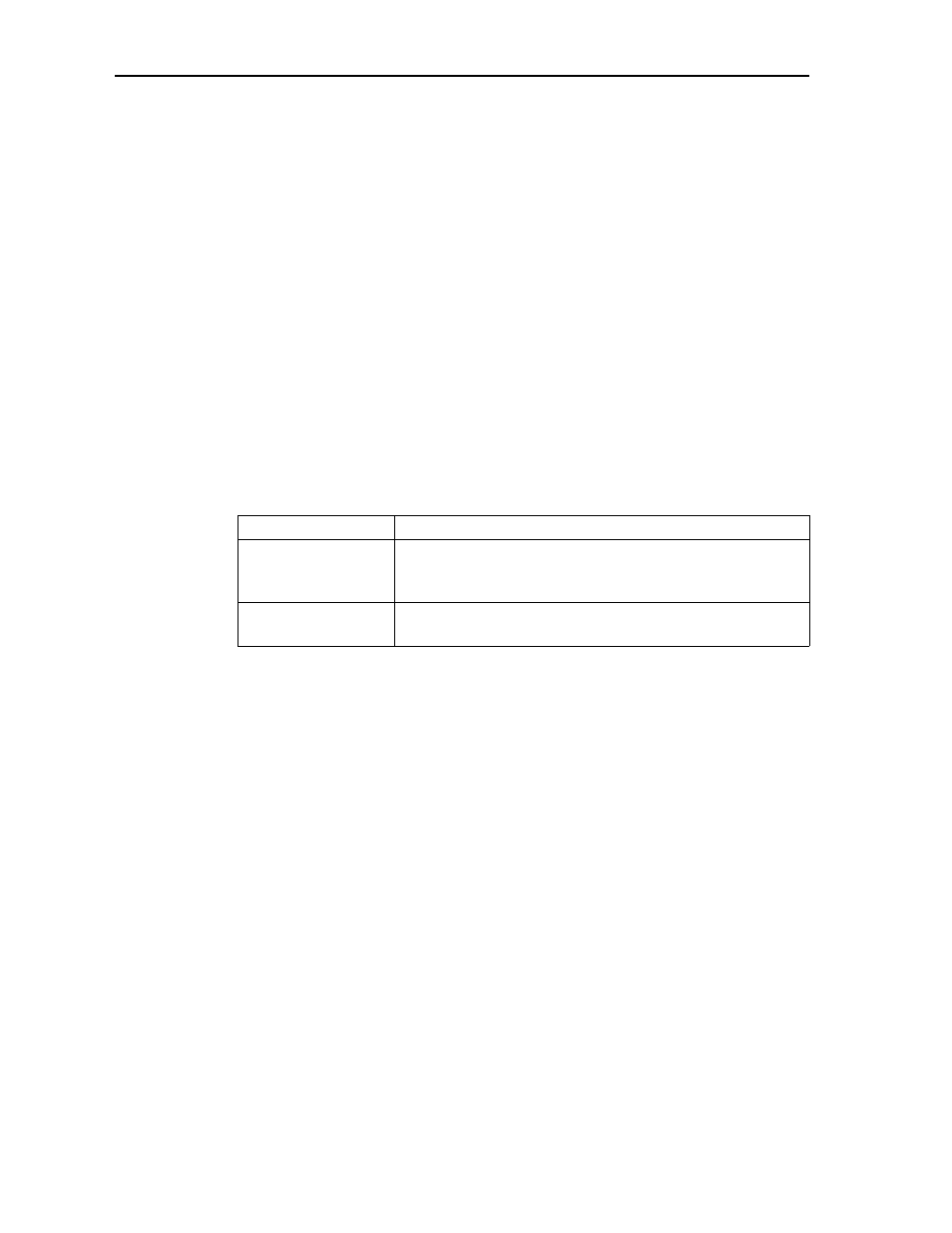

Adhesive

Comments

Loctite 325 with 707

Activator

Cyanoacrylate adhesive. Single component; sets up quickly; use

at temperatures below 200° F; surface must be clean and smooth,

and remove by twisting the sensor.

Versilok 406–Lord

Chemical Products

Structural adhesive. Water resistant; useful to 250° F; cures to

full properties at room temperature in 24 hours.