Removing and installing a shaft key – Rockwell Automation TL-Series Servo Motor User Manual

Page 20

20

TL-Series Servo Motor Installation Instructions

Publication TL-IN001C-EN-P — March 2005

Removing and Installing a Shaft Key

TL shaft keys are constructed of carbon steel. Keys for metric mount motors are

toleranced for interference fit (slightly larger than the opening) to ensure a secure

and rigid fit for the mating connection. Keys for NEMA mount motors are

toleranced for a slightly loose (slip) fit.

To remove an interference fit key:

• Lift the key by grasping it with a plier or similar tool.

• Lever the key with a flat blade screwdriver inserted between the key and the slot.

To install an interference fit key:

• Verify the replacement key matches the keyway in the shaft and the mating

mechanical connection (e.g., coupling or pulley) before proceeding.

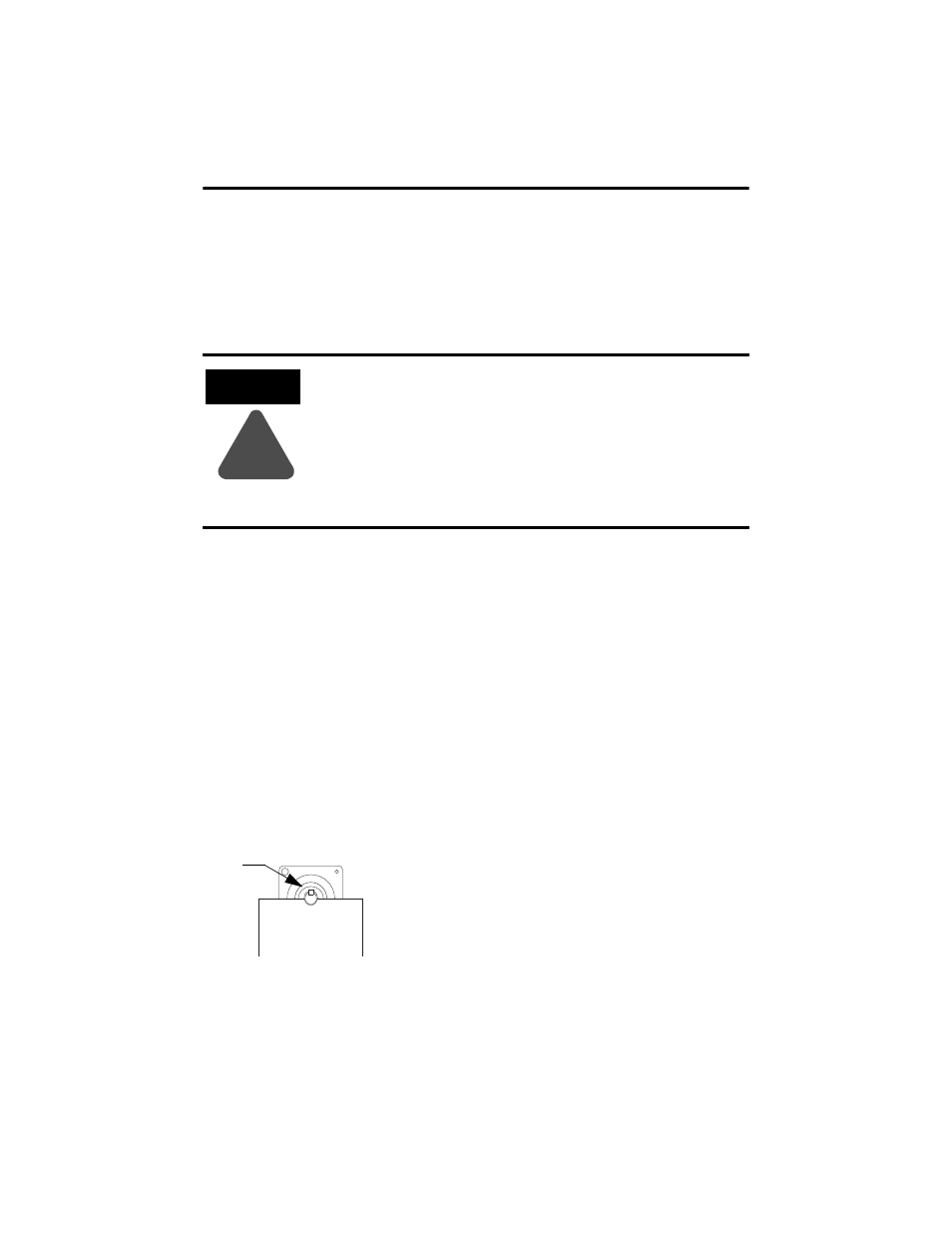

• Support the underside of the shaft diameter with a fixture (Figure 3), and use a

controlled press device to apply a constant force across the top surface to press

the key into the shaft.

Figure 3

Key Alignment and Shaft Support

!

ATTENTION

Damage may occur to the motor bearings and the feedback

device if sharp impact to the shaft is applied during installation

of couplings and pulleys, or a shaft key. Damage to the feedback

device may result by applying leverage from the motor

mounting face to remove devices mounted on the motor shaft.

Failure to observe these safety procedures could result in

damage to the motor and its components.

Shaft

Support for shaft

and/or motor