10 wiring levels and classes – Rockwell Automation SA3100 AC Power Modules User Manual

Page 36

3-18

SA3100 Power Modules

3.10 Wiring Levels and Classes

Drive systems include a wide variety of electrical and electronic circuits. These range

from power circuits that radiate considerable electromagnetic energy to sensitive

electronic circuits susceptible to induced voltages or currents. Solid state digital logic

circuits may be sensitive to transients produced by switching large currents or by

close coupling of field wiring conductors unless properly protected.

System wiring is divided into four basic levels depending upon each circuit’s

susceptibility to noise or its noise-generating capability. The installation wiring for

these levels must be physically separated to prevent poor system performance as a

result of induced noise. Within each level there also may be classes that require

additional grouping and separation of installation wiring. These levels and classes are

defined in ANSI/IEEE Standard 518, Section 6.4.3.1 as follows:

Level 1:

High Susceptibility

Level 2:

Medium Susceptibility

Level 3:

Low Susceptibility

Level 4:

Power

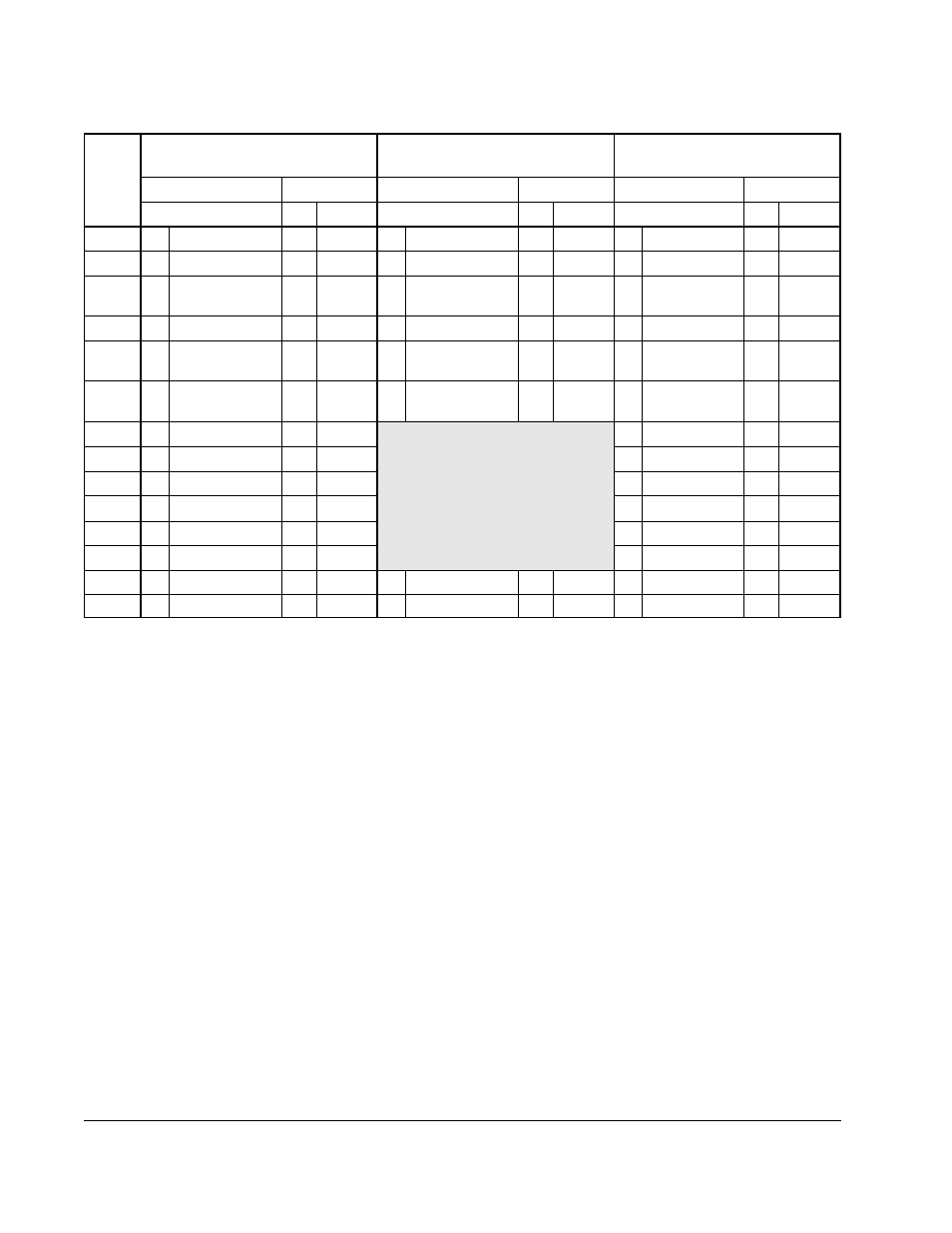

C/W075

1 33.6 (2)

8

54142

1 13.3 (6)

2

54135

1 8.4 (8)

1

54131

C/W100

1 53.5 (1.0)

8

54153

1 13.3 (6)

2

54135

1 13.3 (6)

1

54135

C/W125

1 67.4 (2/0)

8

54158

1 26.7 (3)

2

54147

1 13.3 (6)

1

54135

C/W150

1 107.2 (4/0)

8

54111

1 42.4 (1)

2

54148

1 13.3 (6)

1

54135

C/W200

2 67.4 (2/0)

8

8

54110T

54110B

1 42.4 (1)

2

54148

1 26.7 (3)

1

54142

C/W250

2 85.0 (3/0)

8

8

54111T

54111B

1 67.4 (2/0)

2

54110

1 26.7 (3)

1

54142

C/W300

3 85.0 (3/0)

16 54111

Consult Factory

N/A

N/A

C/W350

3 53.5 (1/0)

24 54109

N/A

N/A

C/W400

3 67.4 (2/0)

24 54110

N/A

N/A

C/W450

3 85.0 (3/0)

24 54111

N/A

N/A

C/W500

3 107.2 (4/0)

24 54112

N/A

N/A

C/W600

3 127.0 (250 MCM) 24 54174

N/A

N/A

W700

-

-

-

-

3 253.0 (500 MCM)

6

54118

1 67.4 (2/0)

1

54110

W800

-

-

-

-

3 253.0 (500 MCM)

6

54118

1 67.4 (2/0)

1

54110

1. Lugs show for DC+ and DC- are based on dynamic brake sizing of 50% of (motor rating x 1.25). select proper lugs based on required

braking torque. Refer to instruction manuals 1336-5.64 or 1336-5.65 for additional information.

2. T & B COLOR-KEYED® Connectors require T & B W117 or TBM-6 Crimper tool or equivalent. Lugs should be crimped according to

manufacturer’s tool instructions. If required, Rockwell Automation can supply lug kits for lugs shown above. Kits do not include crimping

tools. Consult factory for kit information.

3. 5/16 inch stud. All other studs are 3/8 inch.

Table 3.4 – Lug Selection

Power

Module

No.

AC Input R,S,T

Output U,V,W, and PE

DC+ DC-

1

TE

Cable (per phase)

T&B Part No.

2

Cable (per phase)

T&B Part No.

2

Cable (per phase)

T&B Part No.

2

Qty mm

2

(AWG)

Qty Number Qty mm

2

(AWG)

Qty Number Qty mm

2

(AWG)

Qty

Number