Install the replacement slinger – Rockwell Automation MPS-xxxx Stainless Steel Servo Motor User Manual

Page 21

MP-Series Stainless Steel Servo Motor with 100 mm to 165 mm Frame Size 21

Publication MP-IN005F-EN-P - January 2014

Install the Replacement Slinger

1. Install a threaded rod and nut in the shaft alignment hole.

The table below lists the diameter and threading of alignment holes, and a recommended

rod length for each motor.

2. Tighten the nut on the threaded rod against the end of the motor shaft.

This prevents the threaded rod from backing out of the motor shaft during this

removal/installation procedure.

3. Position the slinger squarely on the end of the motor shaft.

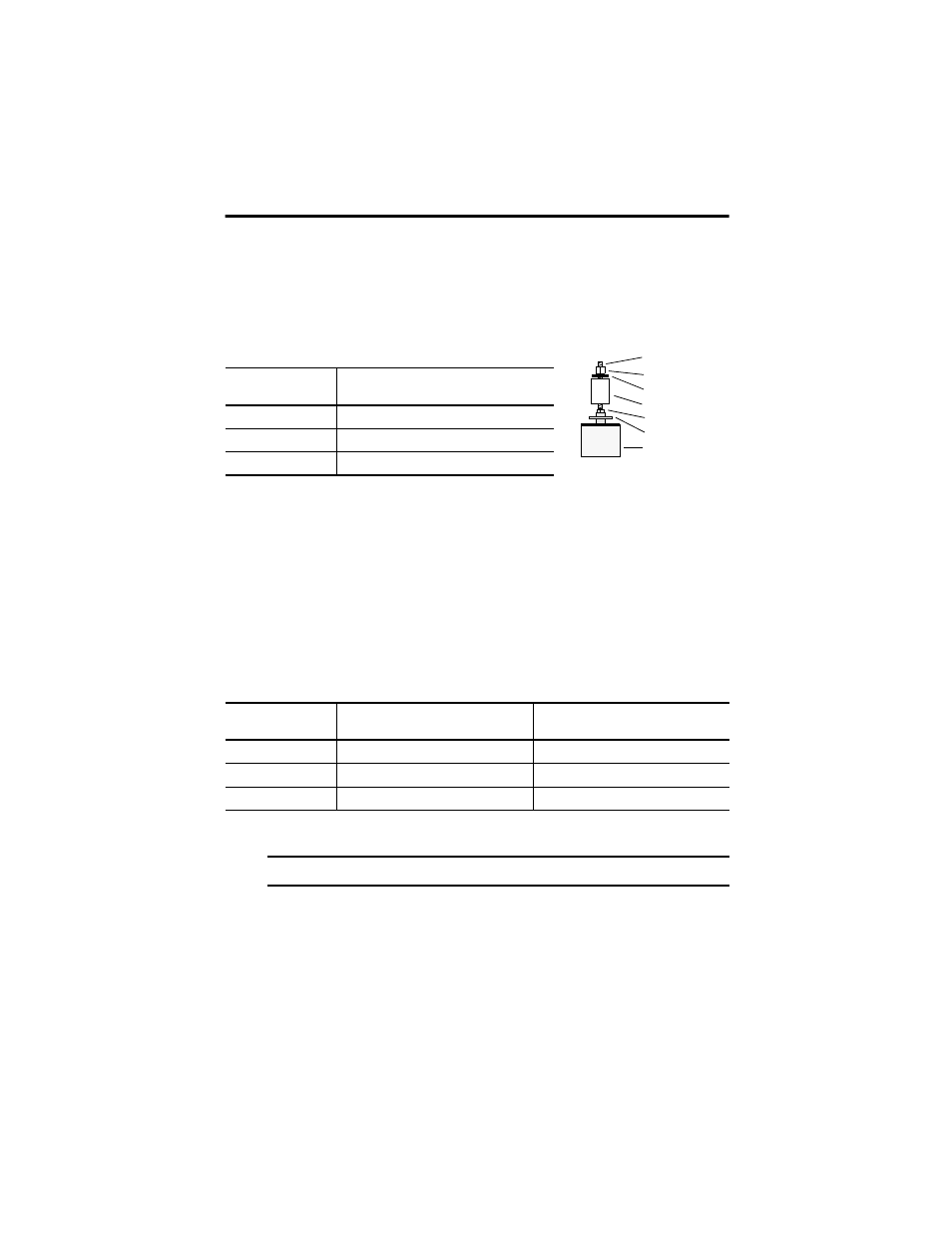

4. Place a deep well socket, a larger washer, and a nut on the threaded rod.

Use a socket larger than the shaft diameter to provide sufficient clearance between the

inside surface of the socket and the motor shaft. The table below lists shaft diameters for

various motor sizes.

5. Tighten the nut to force the washer, socket, and slinger down the shaft.

If additional travel is required to seat the slinger, add a section of hollow pipe or a similar

item behind the socket.

6. Stop moving the slinger down the shaft approximately 3 mm (0.125 in.) before the

slinger contacts the mounting surface of the motor.

Hex Nut and Threaded Rod Sizing

Motor Cat No.

Threaded Rod Size with Recommended Length

mm (in.)

MPS-x330

M5 x 0.8 thread size x 175 (6.9)

MPS-x4540

M8 x 1.25 thread size x 200 (7.9)

MPS-x560

M10 x 1.5 thread size x 225 (8.9)

Motor Shaft and Slinger Diameters

Motor Cat No.

Motor Shaft Diameter

mm (in.)

Slinger Outside Diameter

mm (in.)

MPS-x330 16.0

(0.63) 50.8

(2.0)

MPS-x4540 24.0

(0.945) 63.5

(2.50)

MPS-x560 28.0

(1.1024) 82.6

(3.25)

IMPORTANT

Grasp the slinger tightly by hand to prevent shaft and slinger rotation in the next steps.

Motor

Slinger

Lock Nut

Socket

Washer

Threaded Shaft

Adjustment Nut