Remove and install a shaft key – Rockwell Automation MPS-xxxx Stainless Steel Servo Motor User Manual

Page 18

18 MP-Series Stainless Steel Servo Motor with 100 mm to 165 mm Frame Size

Publication MP-IN005F-EN-P - January 2014

Remove and Install a Shaft Key

Shaft keys for the Bulletin MPS motors are constructed of stainless steel - 300 series. The

specified tolerance provides an interference fit (slightly larger than the opening) for a secure and

rigid connection.

To remove a shaft key, perform one of these actions:

•

Lift the key by grasping it with a pliers or similar tool.

•

Lever the key with a screwdriver inserted between the key and the slot.

To install a shaft key, follow these steps.

1. Verify the replacement key matches the keyway in the shaft and the mating mechanical

connection (for example, a coupling or pulley) before proceeding.

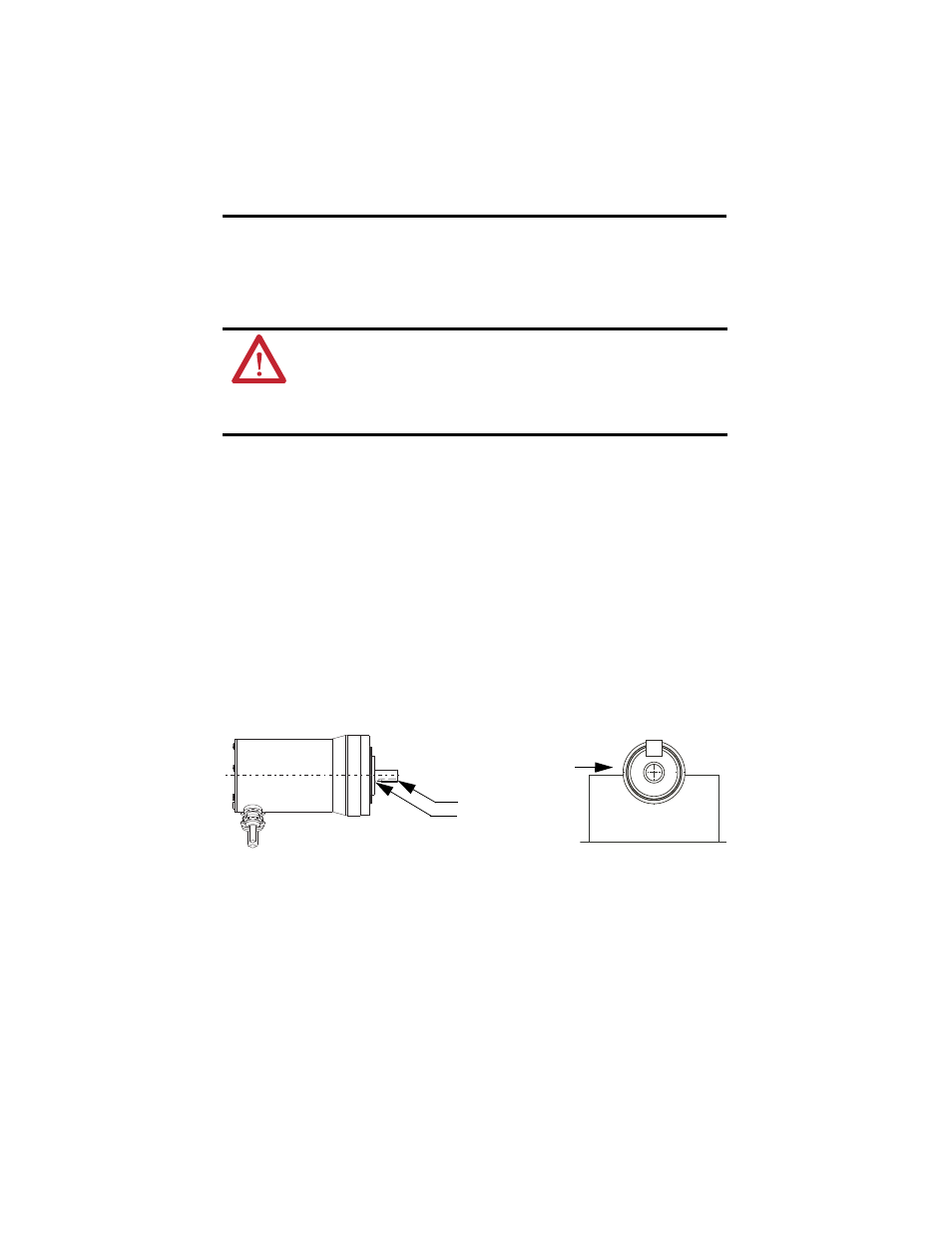

2. Align the front of the key with the front of the motor shaft.

This prevents the radiused end-of-cut at the motor end of the keyway from interfering

with correct seating of the key.

3. Support the underside of the shaft diameter with a fixture, and use a controlled press

device to apply a constant force across the top surface to press the key into the shaft.

Key Alignment and Shaft Support

ATTENTION: Do not strike the motor’s shaft, couplings, or pulleys with tools during installation or removal of the

shaft key.

Damage can occur to the motor bearings and the feedback device if a sharp impact is applied to the shaft during

installation of couplings and pulleys, or to remove the shaft key, or if leverage is applied from the motor mounting

face to remove devices mounted on the motor shaft.

Apply a constant pressure, with a wheel puller, to the user end of the shaft to remove a friction fit or stuck device.

Key Alignment

Radiused Cut for

Keyway

Key

Shaft

Support for Shaft

and Motor