Rockwell Automation 2100 CENTERLINE Motor Control Center (MCC) Units with Horizontal Operating Handl User Manual

Page 8

8

Rockwell Automation Publication 2100-IN060D-EN-P - March 2014

CENTERLINE 2100 Motor Control Center (MCC) Units with Horizontal Operating Handles

3. Install other cables or devices.

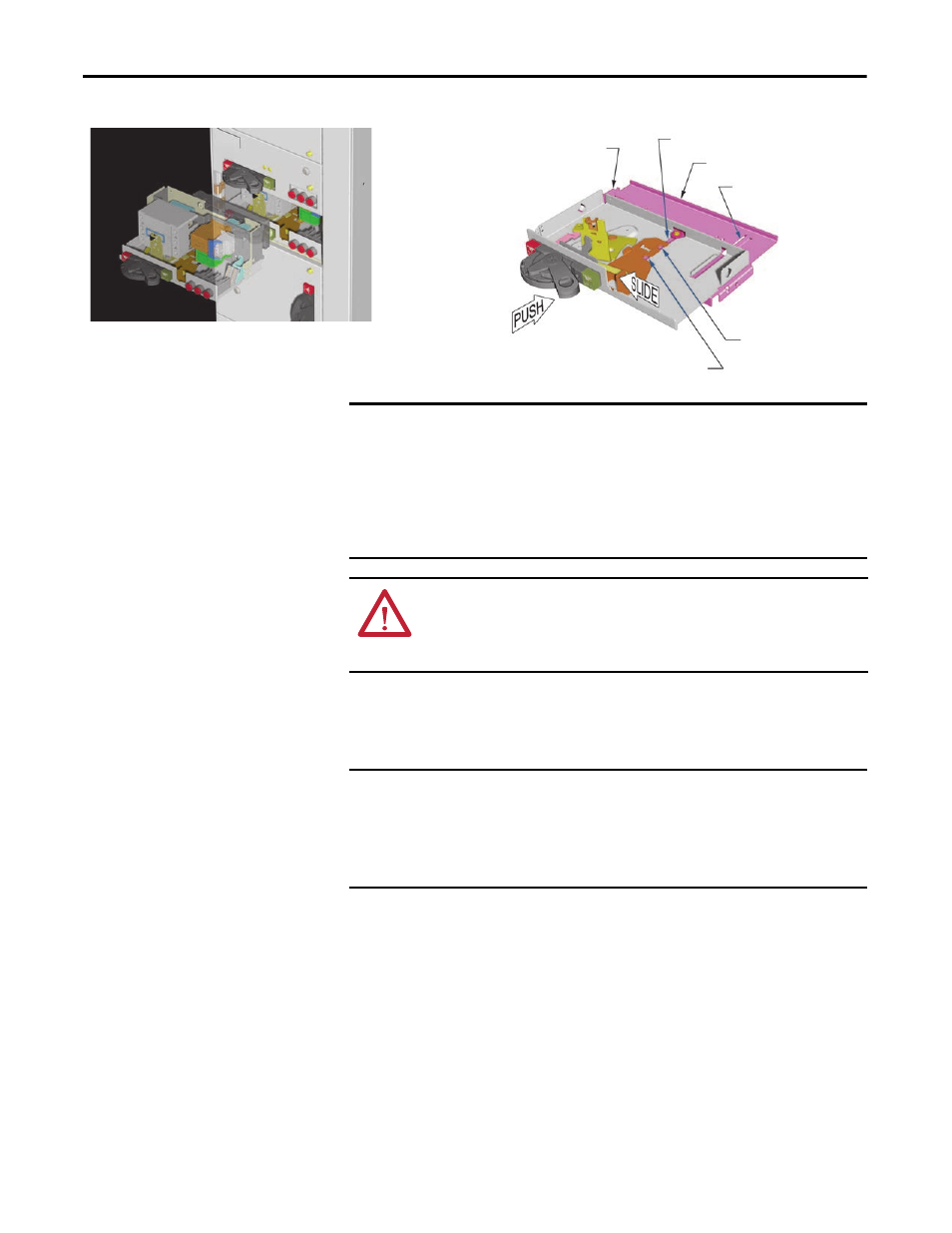

Bushing Slot

Unit Support Pan

Right Unit Guide

Left Unit Guide

Disconnected Position

Normal Operating Position

Unit devices have been

omitted for clarity.

IMPORTANT

Note that there are two positions available (normal operating and

disconnected). In the normal operating position, the power and ground stabs

are connected to their respective busses. In the disconnected position, the unit

is partially removed from the MCC and the intermediate slot in the interlock

plate is in line with the bushing located in the unit support pan. When the unit

is locked in this position, the unit power and ground stabs are disengaged. This

position can be used to prevent insertion of a unit into the MCC.

ATTENTION: For proper operation of the latch/interlock mechanism, a style 3

unit-support pan with bushing must be used below the unit. If the unit support

pan with bushing is not used, the unit could be removed under load, resulting in

injury or death.

TIP

For the CENTERLINE 2100 MCC units with swing-out door latches, it is

necessary to rotate the movable portion of the latch bracket to a vertical

orientation to avoid interference when installing the unit.

IMPORTANT

Be sure to comply with the National Electric Code 6.7 ft (2 m) unit handle-to-

floor height limitation, as identified in NEC 2005 Article 404.8(A) and UL

standard 845, for units in the topmost location of a vertical section.

A unit operating handle extender kit, catalog number 2100H-NE1, is available

for any handles higher than 6.7 ft (2 m) off of the ground.