Dielectric test – Rockwell Automation 7703E Medium Voltage SMC OEM Components - 10-15 kV User Manual

Page 40

40

Rockwell Automation Publication 7703E-IN001E-EN-P - July 2014

Chapter 7

Final Test Procedures

• The bypass vacuum contactor or breaker (and capacitor contactor if

applicable) must have a fast drop-out time (typically 100 milliseconds or

less).

Dielectric Test

1. Remove the ribbon cable and ground wires from the voltage sensing board,

and isolate the ends to prepare for the Hi-Pot test.

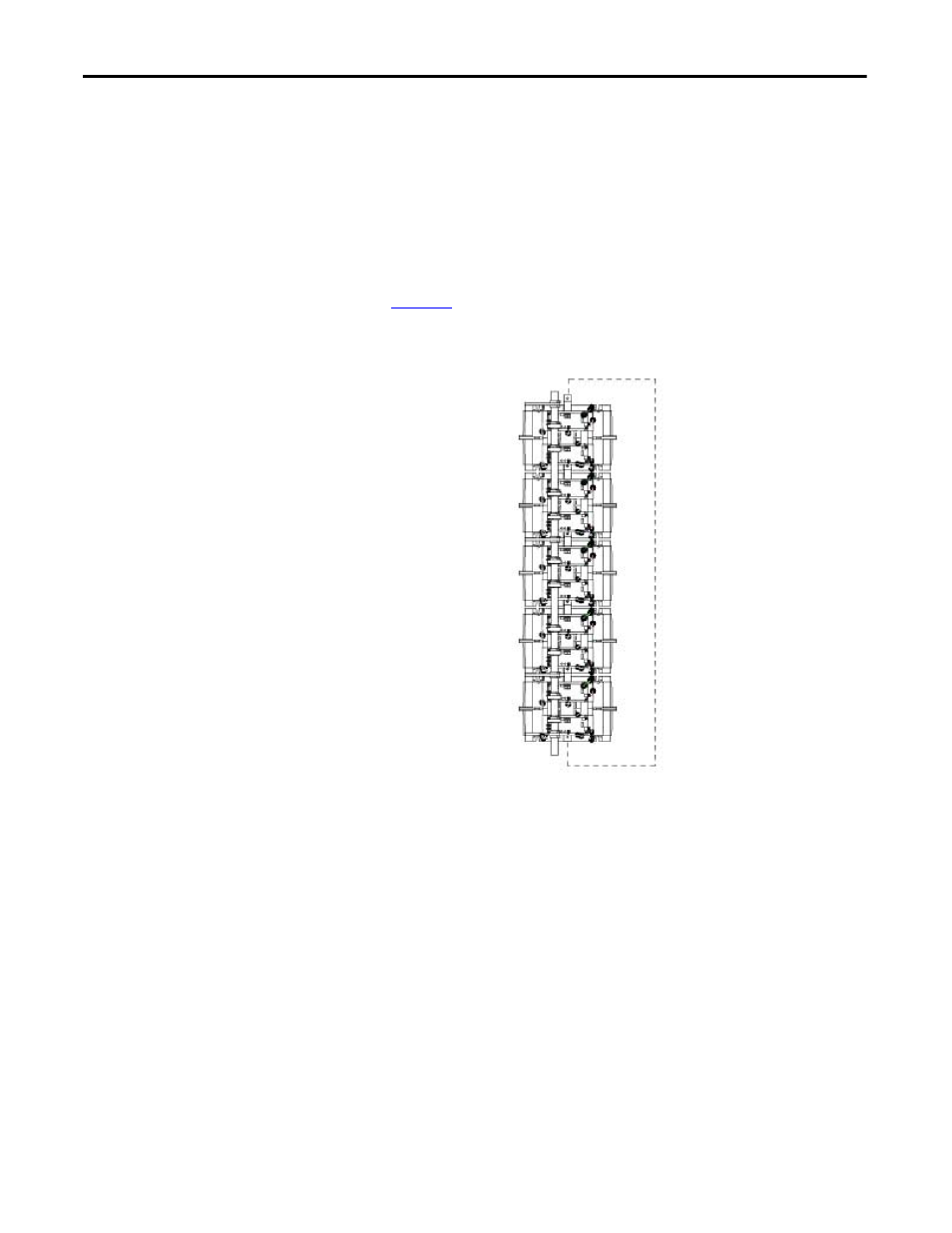

2. Jumper the line and load terminals together within each phase as shown in

.

Figure 19 - Example of Jumper Positioning for Hi-pot Test

3. Measure the resistance between the line and load sides of each PowerBrick

phase assembly to make sure there is zero resistance. This indicates that the

jumpers are properly set.

4. Perform a Hi-Pot test as required by the applicable local codes and

standards. Typical levels for field testing are two times the rated voltage of

the equipment.

5. After the Hi-Pot remove the heatsink jumpers. Re-connect the feedback

board wires.

6. Perform a resistance check for each SCR. The SCR resistance can be

checked directly at the device or at the leads on the gate driver board.

a. The gate-to-cathode resistance should range from 10…40 ohms for all

styles.

b. The cathode-to-cathode resistance can also be checked and should be

between 20…32 ks per brick.

Jumper