Dimensions, Torque requirements, Powerbrick mounting – Rockwell Automation 7703E Medium Voltage SMC OEM Components - 10-15 kV User Manual

Page 13: Dimensions torque requirements powerbrick mounting

Rockwell Automation Publication 7703E-IN001E-EN-P - July 2014

13

PowerBrick™ Installation

Chapter 3

Dimensions

Refer to

, and

for PowerBrick dimensions and

mounting.

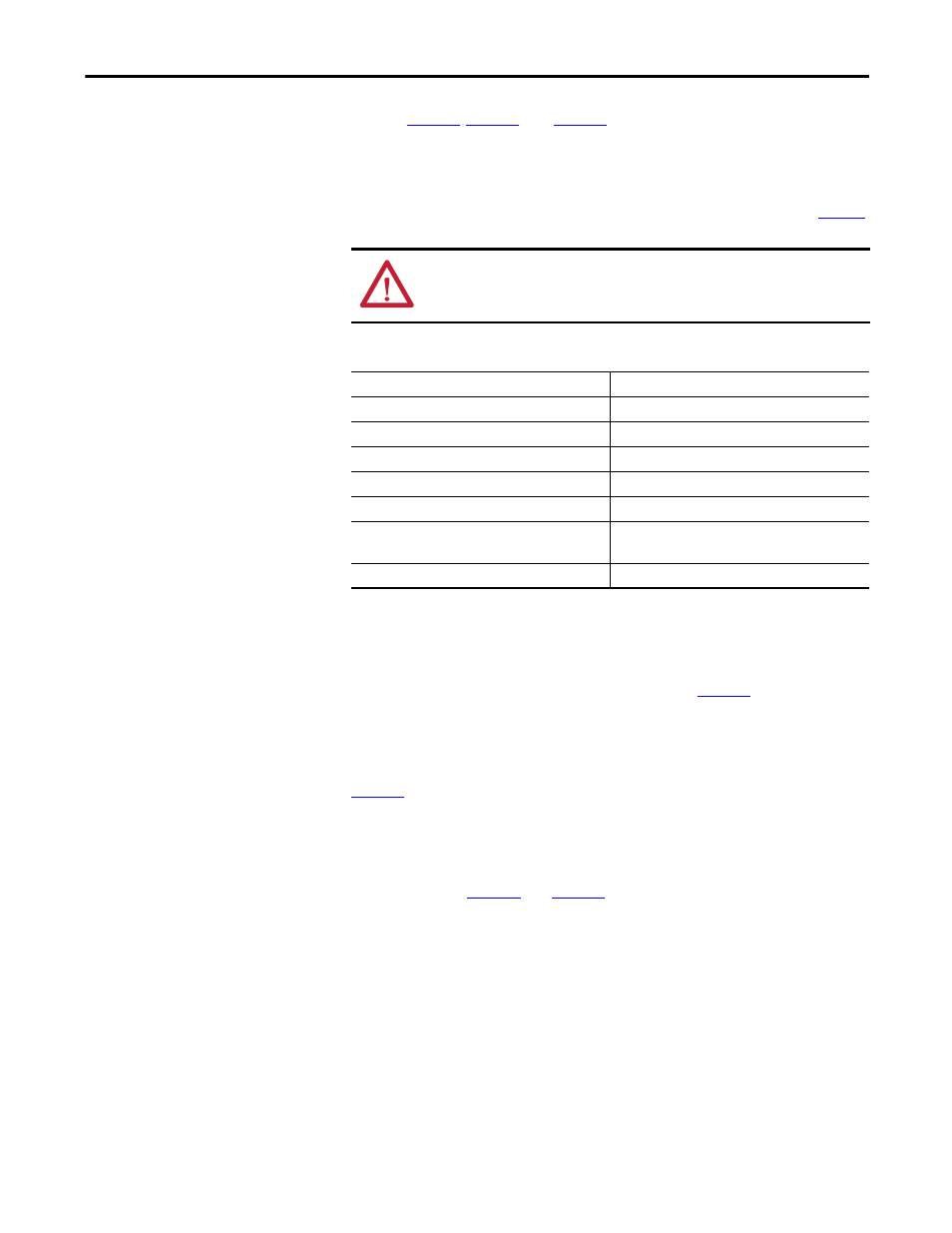

Torque Requirements

All electrical connections must be torqued to the specifications shown in

.

Table 4 - Torque Requirements

PowerBrick Mounting

PowerBricks are to be mounted in a vertical orientation in order to provide

adequate component cooling. Mount the PowerBricks in a suitable location using

the mounting holes provided in the assembly (refer to

). Use

M8 (5/16 in.) or similar hardware for the mounting hole dimensions of

10.7 x 15.9 mm (0.421 x 0.625 in.).

PowerBricks are provided with two methods for mounting (as shown in

). The PowerBricks can be mounted to a vertical surface using the four

mounting locations on the rear face, or they can be mounted to a horizontal

surface using the four mounting locations on the base.

Note: Using either mounting option requires space above and below each phase

assembly (refer to

ATTENTION: Ensure that all electrical connections are torqued to the correct

specification. Failure to do so may result in damage to the equipment and/or

injury to personnel.

Hardware

Recommended Torque

¼-20 thread cutting housing assembly screws

7 N•m [62 lb•in]

M5

3.4 N•m [30 lb•in]

Control Wire Terminals

0.2…0.4 N•m [2.0…3.3 lb•in]

CLGD Power Assembly Terminals

5.6 N•m [50 lb•in]

SMC Flex Control Module Terminals

0.6 N•m [5in•lb]

M8, Capacitor Lugs

M8, All others

7.5 N•m [66 lb•in]

14 N•m [120 lb•in]

M10

29 N•m [250 lb•in]