Removing wooden skids, Removing lifting angles, Removing wooden skids removing lifting angles – Rockwell Automation 7000 PowerFlex Medium Voltage Air-Cooled (B Frame) Trans.& Handling - ForGe User Manual

Page 23

Rockwell Automation Publication 7000-IN008C-EN-P - April 2013

23

Transportation and Handling Procedures Chapter 2

1. Insert forks into the shipping skid openings from the rear of the drive.

2. Carefully balance the drive on the forks (drives are usually heavier on one

side).

3. Use safety straps to steady the drive while moving.

Removing Wooden Skids

Remove the wooden shipping skids only when the drive is in its final installation

location. At the back of the drive there are steel angle brackets holding the

equipment to the wooden shipping skid. Open the front doors of the equipment

to reach and remove the lag screws that attach the angles to the equipment.

Lift the drive using overhead lifting angles and slide the wooden shipping skid out

from under the equipment.

If an overhead lifting with a crane is not available, use two lift trucks with a

combined capacity equal to the entire drive. Lift the drive using the overhead

lifting angles and suitable spreader bars attached to the forklift trucks.

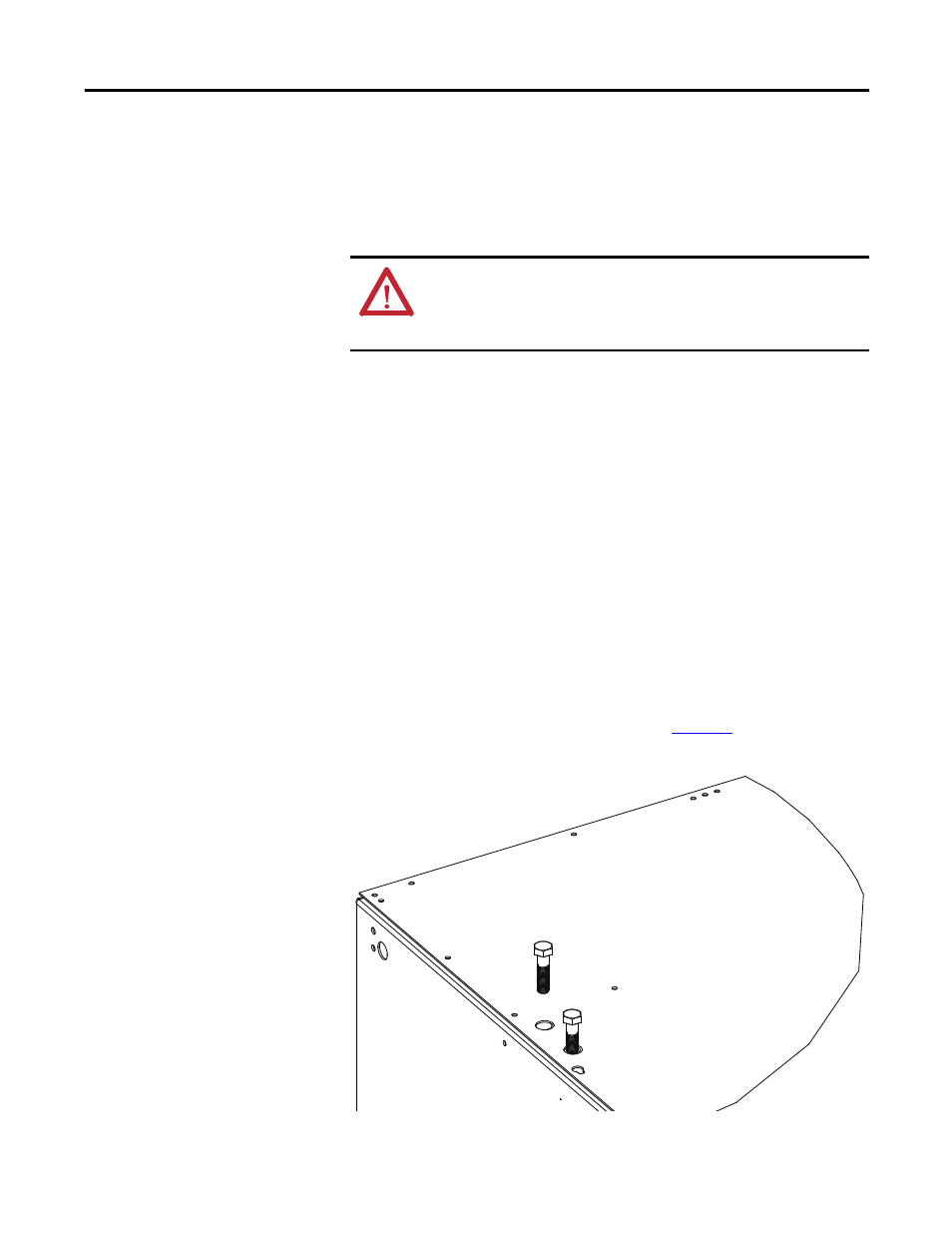

Removing Lifting Angles

Remove lifting angles only when the drive is in its final position. The lifting

angles attach to the drive using 5/8”-11 hardware. Reinstall the 5/8” bolts in their

holes in the top of the drive to seal the bolt-holes (

).

Figure 17 - Insert bolts

WARNING: Take care when using either a forklift or the pipe rolling technique

for positioning purposes, to ensure that the drive is not scratched, dented, or

damaged. Stabilize the drive during handling to guard against tipping and

injury to personnel.