Rigging contractor, Overhead lifting, Rigging contractor overhead lifting – Rockwell Automation 7000 PowerFlex Medium Voltage Air-Cooled (B Frame) Trans.& Handling - ForGe User Manual

Page 18

18

Rockwell Automation Publication 7000-IN008C-EN-P - April 2013

Chapter 2 Transportation and Handling Procedures

Rigging Contractor

Rockwell Automation strongly recommends that you contract professional

riggers with suitably-rated lifting equipment to move the drive to its final

installation site.

Overhead Lifting

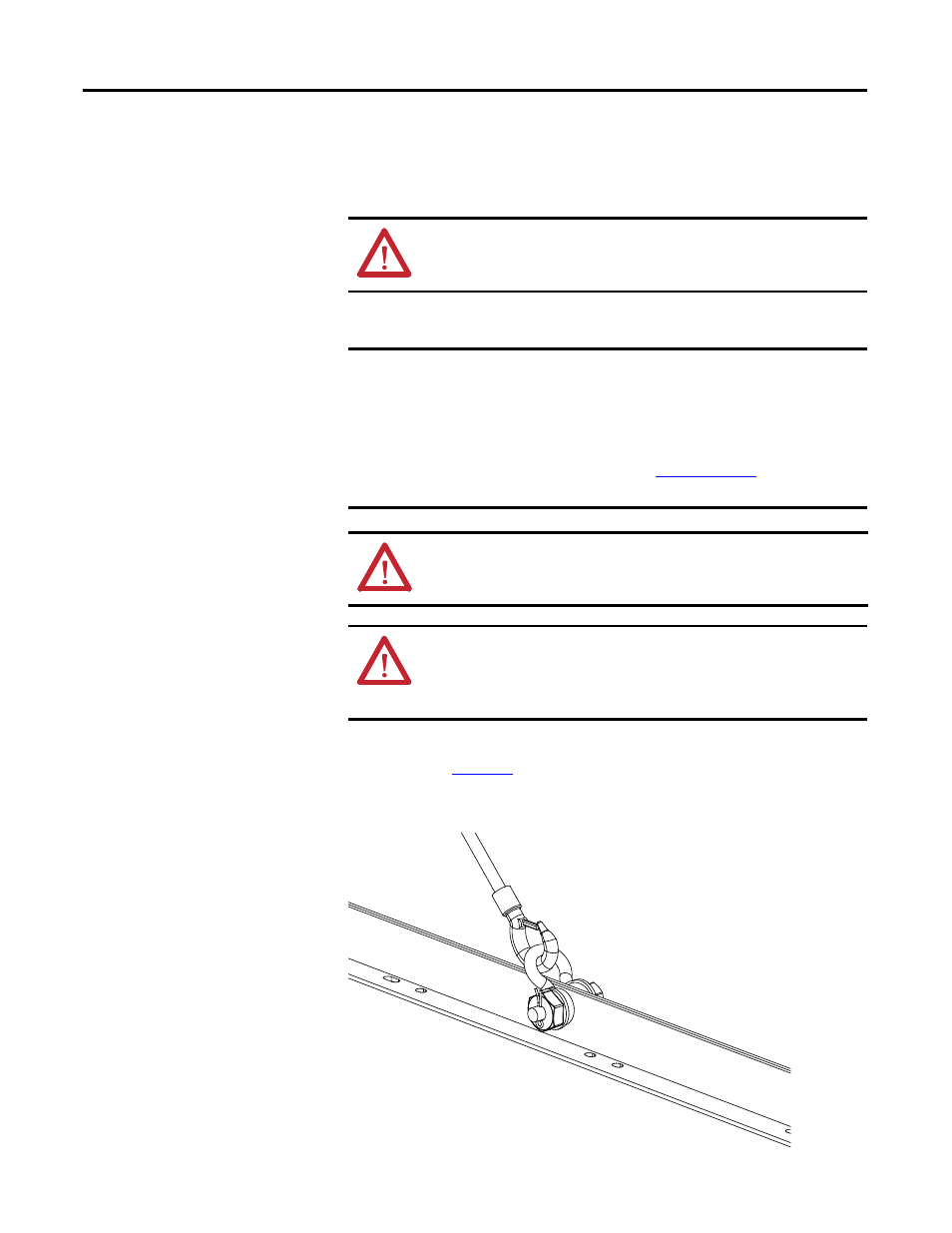

1. Use shackles in the holes of the lifting angles and use safety hooks in the

shackles (

). Do not pass slings or cables through the holes of the

lifting angles. Use only 38 mm (1.5 in.) diameter holes for shackles.

Figure 11 - Shackle attached to Drive lifting angle

ATTENTION: Do not lift or move the drive by any means other than the

handling methods listed in this publication. Failure to do so may result in

personal injury or equipment damage.

IMPORTANT

For the largest direct-to-drive VFDs, the common mode chokes (CMCs) are

relatively heavy (5000 lb/2267 kg). To ease handling of the VFD enclosure, the

CMCs are shipped separately and the contractor or customer must reinstall the

CMC into the VFD enclosure onsite. The CMC is completely installed and tested

at the factory before being removed for shipment.

See Rockwell Automation publication

for instructions on

installing a separately shipped CMC.

WARNING: Do not stand underneath the drive unit at any time during the

overhead lifting. Follow local regulations and codes regarding health and safety

at all times.

ATTENTION: Load ratings of the lifting device, slings, hooks, and shackles must

have a lifting capacity rated equal to or greater than the load. Failure to do so

may result in personal injury and/or equipment damage. For your drive’s

specific weight, refer to shipping weights on the packing slip.