Install the right angle cables, Right-angle power/brake cables – Rockwell Automation 2090-CFxxx 2090-Series Motor/Actuator Cable Installation Instructions User Manual

Page 15

Rockwell Automation Publication 2090-IN050B-EN-P - July 2014

15

2090-Series Motor/Actuator Cables

Install the Right Angle Cables

Follow these steps to attach a right-angle cable connector to the motor connector.

1. Align all flat surfaces on the cable connector with the flat surface on the

motor connector.

2. Push the cable connector onto the motor connector to fully seat the

connection.

3. Twist the knurled front end of the cable connector clockwise

approximately 60° to secure the connection.

Right-angle Power/Brake Cables

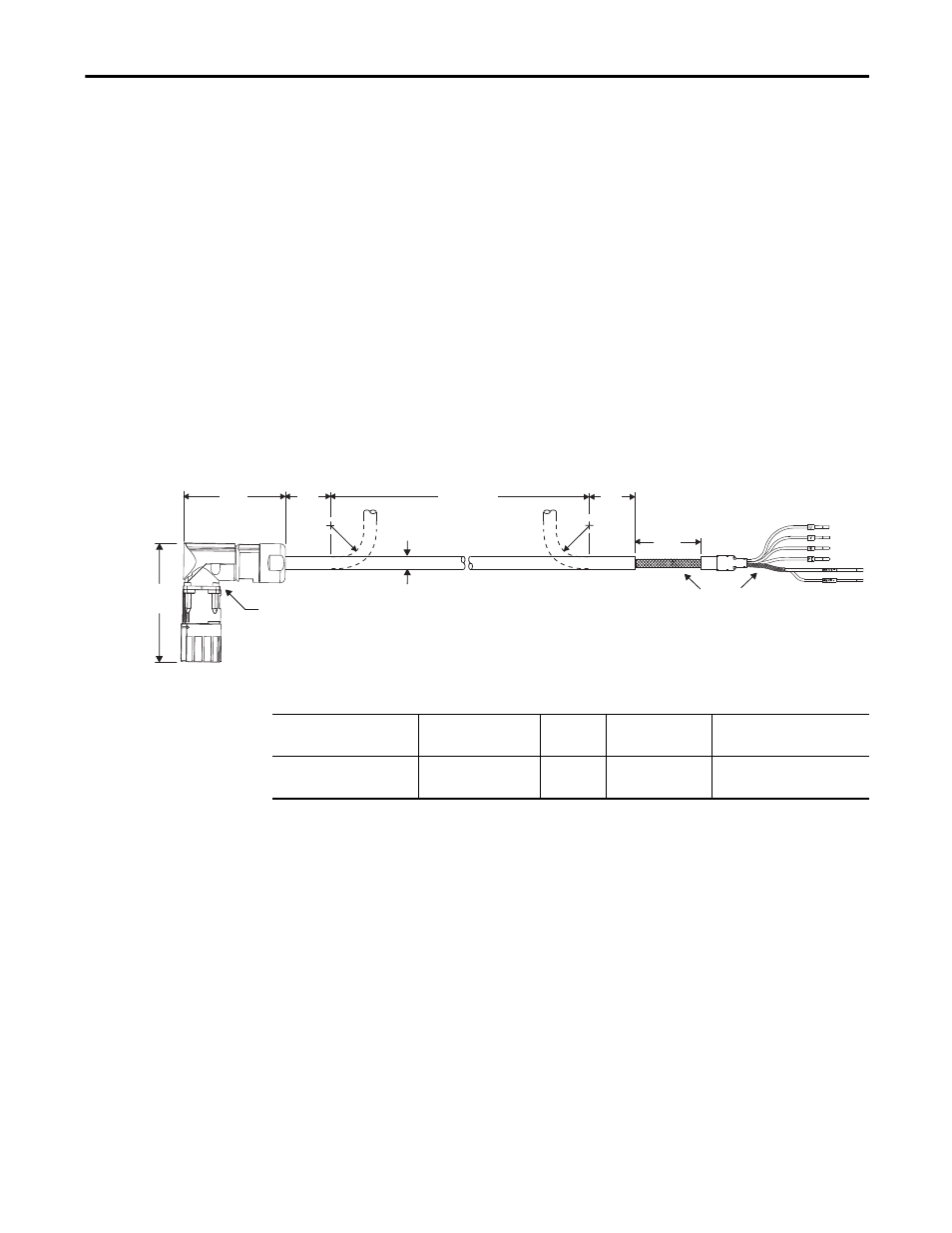

This figure illustrates how to measure the bend radius and where cable bends can

be made on right-angle power/brake cables.

Figure 6 - Right-angle Power/Brake Cable Bend Radius Example

Table 14 - Right-angle Power/Brake Cable Specifications

You can reposition right-angle power cables in 90° increments. Follow these steps

to reposition the power cable connector.

1. Remove the four 2 mm hex screws on the back of the cable connector.

2. Reposition the connector body to a new position by rotating the

connector 90°, 180°, or 270°.

3. Secure the two parts together with the four 2 mm hex screws.

Torque screws to 0.25 N•m (2.2 lb•in), maximum.

71.0

(2.8)

82.0

(3.2)

150

(5.9)

11.6

(0.46)

81.2

(3.2)

81.2

(3.2)

Bend Area

Cable

Diameter

Hex Screw (4x)

Cable

Shields

Power/Brake Cable Type

Cable Cat. No.

Wire Size

AWG

Available Lengths

mm (in.)

Connector IP Rating

Right-angle power/brake cable

(standard, non-flex)

2090-CPBM7DF-16RA

xx

16 (power)

18 (brake)

3, 6, 9, 15 m

(10, 16, 30, 49 ft)

IP54

(dust protected, splashing water)