Rockwell Automation Logix5000 Controllers Tasks, Programs, and Routines Programming Manual User Manual

Page 10

Chapter 1 Manage tasks

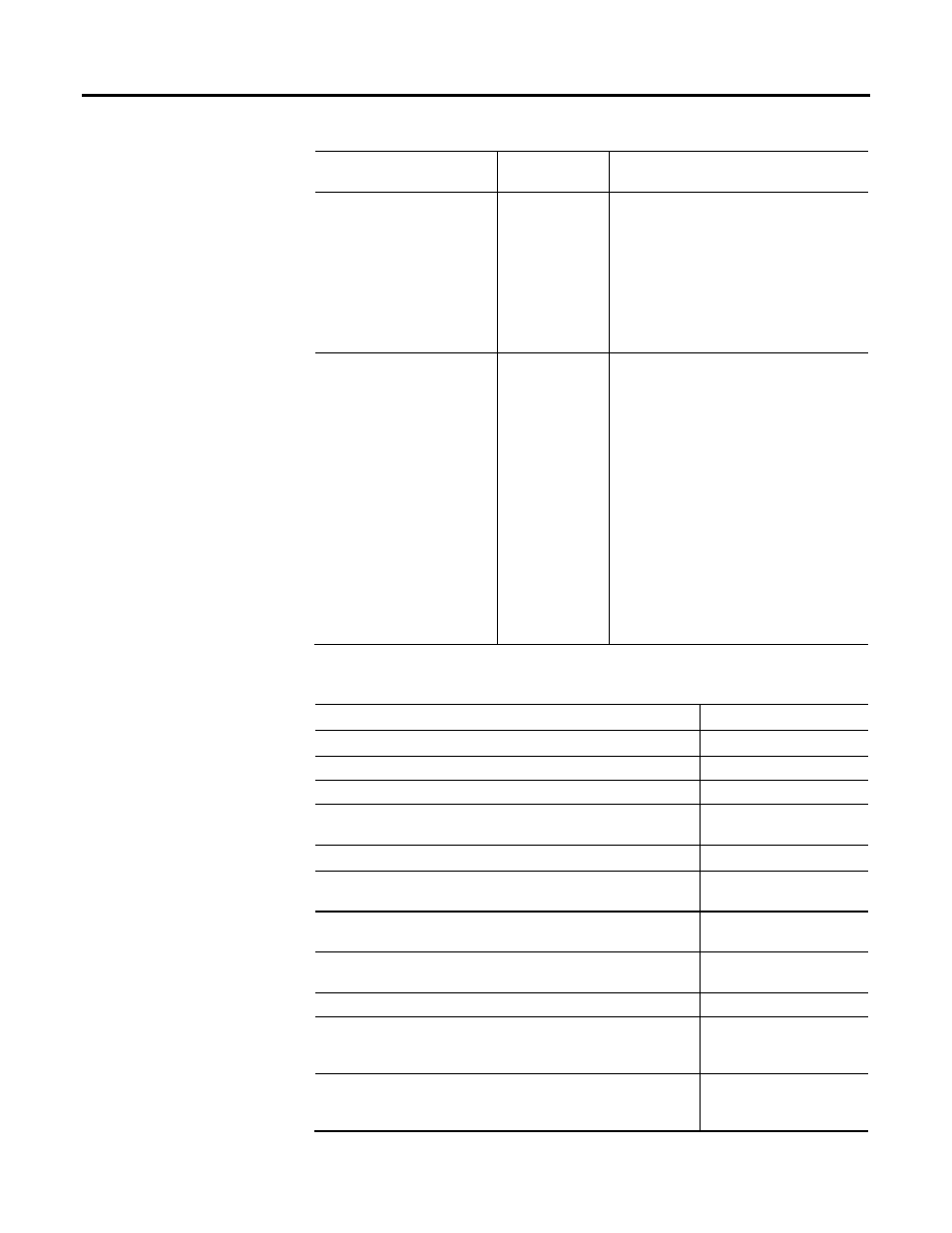

If you want to run a section of your

logic

Then use this type of

task

Description

•

At a constant period (for

example, every 100 ms)

•

Multiple times within the scan of

your other logic

Periodic Task

A periodic task performs a function at a specific period.

When the time for the periodic task expires, the periodic

task:

•

Interrupts any lower priority tasks.

•

Runs one time.

•

Returns control to where the previous task left off.

You can configure the time period from 0.1 ms…2000 s.

The default is 10 ms.

Immediately when an event occurs

Event Task

An event task performs a function only when a specific

event (trigger) occurs. When the trigger for the event task

occurs, the event task:

•

Interrupts any lower priority tasks.

•

Runs one time.

•

Returns control to where the previous task left off.

The trigger can be a:

•

Change of a digital input.

•

New sample of analog data.

•

Certain motion operations.

•

Consumed tag.

•

EVENT instruction.

Important: Some Logix5000 controllers do not support

all triggers.

The following table lists example situations for the tasks.

For this example situation

Use this type of task

Fill a tank to its maximum level and then open a drain valve.

Continuous task

Collect and process system parameters and send them to a display.

Continuous task

Complete step 3 in a control sequence—reposition the bin diverter.

Continuous task

Your system must check the position of a field arm each 0.1 s and calculate the average

rate of change in its position. This is used to determine braking pressure.

Periodic task

Read the thickness of a paper roll every 20 ms.

Periodic task

A packaging line glues boxes closed. When a box arrives at the gluing position, the

controller must immediately run the gluing routine.

Event task

In a high-speed assembly operation, an optical sensor detects a certain type of reject.

When the sensor detects a reject, the machine must immediately divert the reject.

Event task

In an engine test stand, you want to capture and archive each analog data immediately

after each sample of data.

Event task

Immediately after receiving new production data, load the data into the station.

Event task

In a line that packages candy bars, you have to make sure that the perforation occurs in

the correct location on each bar. Each time the registration sensor detects the

registration mark, check the accuracy of an axis and perform any required adjustment.

Event task

A gluing station must adjust the amount of glue it applies to compensate for changes in

the speed of the axis. After the motion planner runs, check the command speed of the

axis and vary the amount of glue, if needed.

Event task

10

Rockwell Automation Publication 1756-PM005-EN-P - October 2014