Rockwell Automation 1771-IXE/D Thermocouple/Millivolt Input Module User Manual User Manual

Page 46

6–6

Module Calibration

Publication 1771Ć6.5.130 Ć May 1999

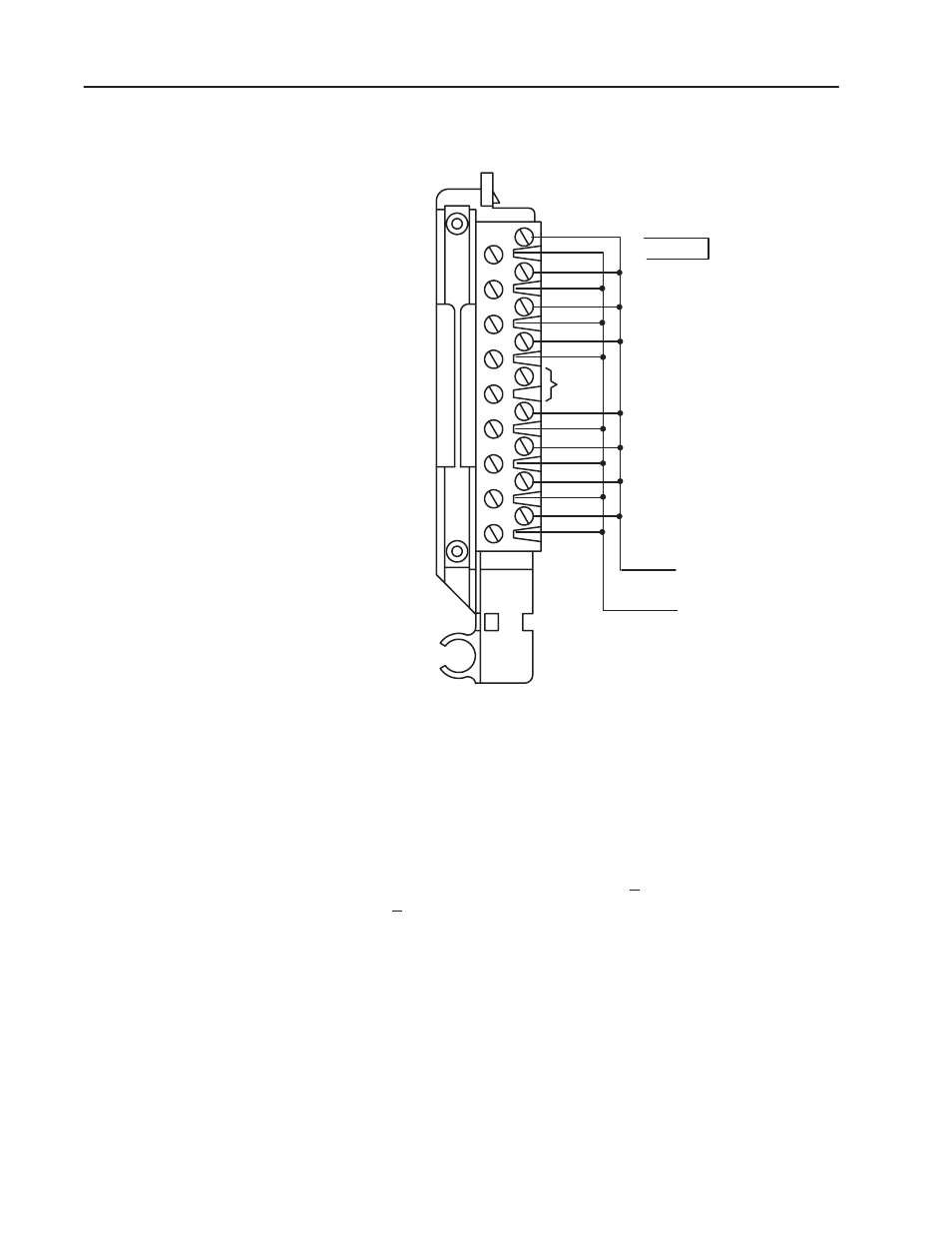

Figure 6.4

Shorting Inputs for Offset Calibration

1

Do not

use

18

Input 1 (+ lead)

17

Input 1 (- lead)

16

Input 2 (+ lead)

15

Input 2 (- lead)

14

Input 3 (+ lead)

13

Input 3 (- lead)

12

Input 4 (+ lead)

11

Input 4 (- lead)

10

Not Used

9

Not used

8

Input 5 (+ lead)

7

Input 5 (- lead)

6

Input 6 (+ lead)

5

Input 6 (- lead)

4

Input 7 (+ lead)

3

Input 7 (- lead)

2

Input 8 (+ lead)

1

Input 8 (- lead)

Terminal Identification

Terminal

Function

Wiring Arm

Cat. No. 1771-WI

18

17

16

1

15

14

13

12

11

10

9

8

7

6

5

4

3

2

Repeat for each channel

Apply

0.000mV

Short each input,

or apply 0.000mV

across each input

channel.

Shorting link.

10532-I

3. Observe the input value read by the processor (word 4 of the BTR

file for channel 1). It should be 0000.

4. Multiply the difference between your observed value and 0.000

by 3.0933. Determine the magnitude and sign of the required

correction.

You can adjust the correction up to +127 binary counts

(+410.56

µ

V).

A negative correction means that the reading was too high and

you want to subtract a corrective amount from that reading.

A positive correction means that the reading was too low and you

want to add a corrective amount to that reading.

5. Enter the magnitude and sign of the correction in binary code into

the upper (offset correction) byte of the calibration word for that

channel. (BTW file, word 20, bits 17–10 for channel 1.)