Considerations for the +/- 15v dc supply, Considerations for the " 15v dc supply, Selection of the " 15v power supply – Rockwell Automation 1746-QV,D17466.18 OPEN-LOOP VELOCITY CONTL User Manual

Page 19

4–3

Setting Up the Hardware

Publication 1746-6.18 April 1998

•

run shielded cables only in low-voltage conduit

•

place the SLC-500 processor, power supply, and I/O chassis

assembly in a suitable enclosure

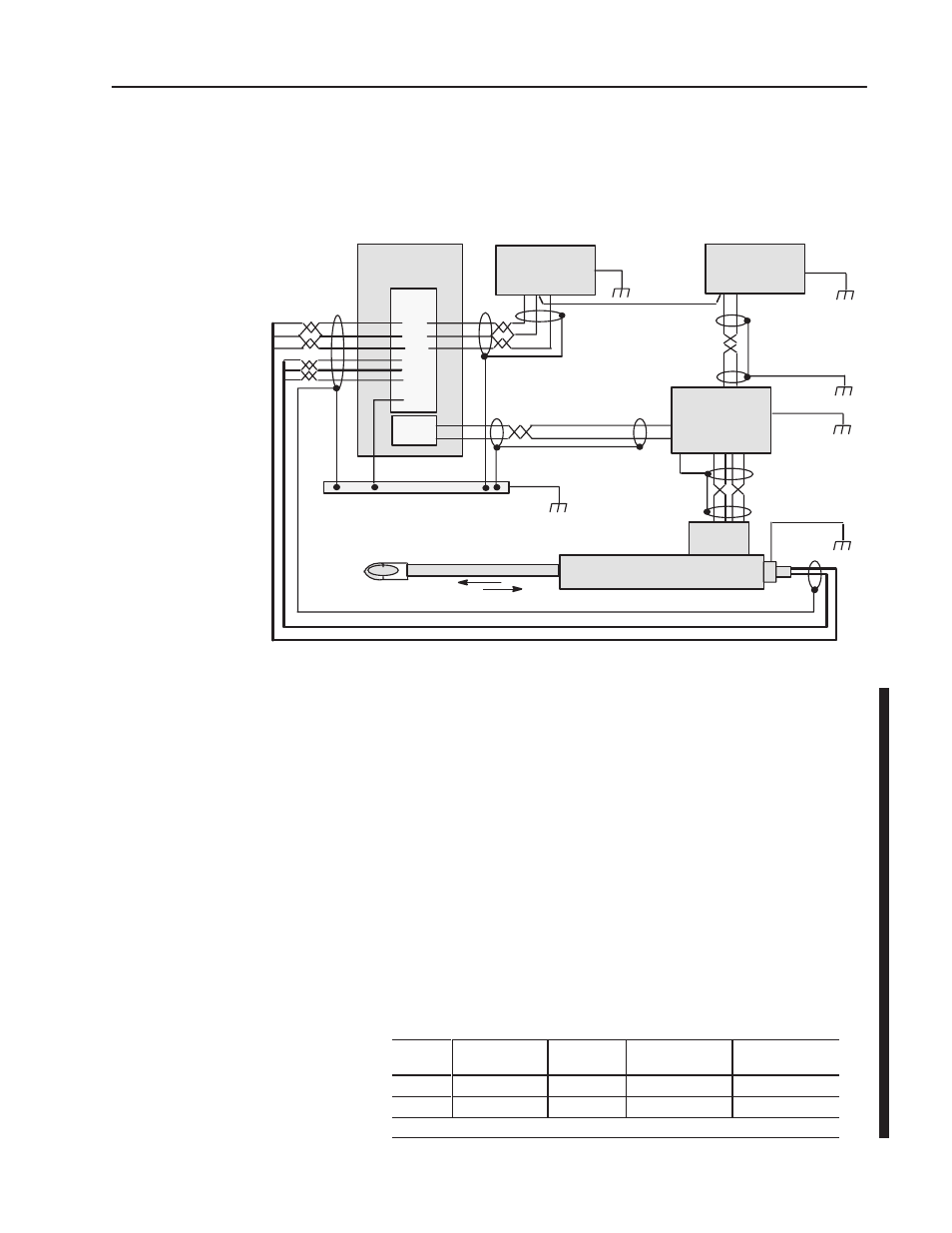

Typical grounding and shielding for this type of control system:

1746-QV

Module

LDT and Hydraulic Ram

Analog Output

Valves

Servo

Proportional

Amplifier

LDT

Signals

24V Power

Supply

"15V Power

Supply

4

earth ground

2

(–) (+)

(+) (C) (–)

Output

Input

Belden

8761

Belden

8761

Case

GND

Case

GND

Case

GND

Cable

Note

Cable

Note

Cable Note: Use cable

recommended by the LDT

and amplifier manufacturer.

Belden

8770

3

1

5-8

LDT

Power

Piston-type Hydraulic Cylinder and

Linear Displacement Transducer (LDT)

0V

Selection of the

"15V Power Supply

The positive and negative supply of some

"15V dc power supplies

decay at different rates when ac power is removed. The module’s

output will be biased, based upon the difference in voltage level

between the positive and negative supply. The duration is dependent

upon the magnitude of the difference and the decay rate. For these

reasons, the

"15V dc power supply should have or be equipped with:

•

proper interlocks with machine operation and e-stop circuits

•

an internal voltage-sense relay that drops the

"15V (without

variation in decay rates) upon loss of ac power

•

auxiliary relay to indicate proper operation and voltage

(such as loss of +15V but not –15 V dc)

Power Supply Loading

The module and LDT load the power supply typically as follows:

Supply

No Transducer

No Load

Transducer

Only *

LDT + Module:

+10V dc @ 10mA

LDT + Module:

–10V dc @ 10mA

+15V dc

86mA

128mA

141mA

128mA

–15V dc

14mA

30mA

30mA

40mA

*MTS Temposonics II, model T1SR0U0120R (Other LDTs will have different loading.)

Considerations for the

"15V dc Supply