Control with solid-state devices – Rockwell Automation 1503 IntelliVAC Contactor Control Module - Series C and later User Manual

Page 25

3-12

Installation and Wiring

1503-UM052D-EN-P – June 2013

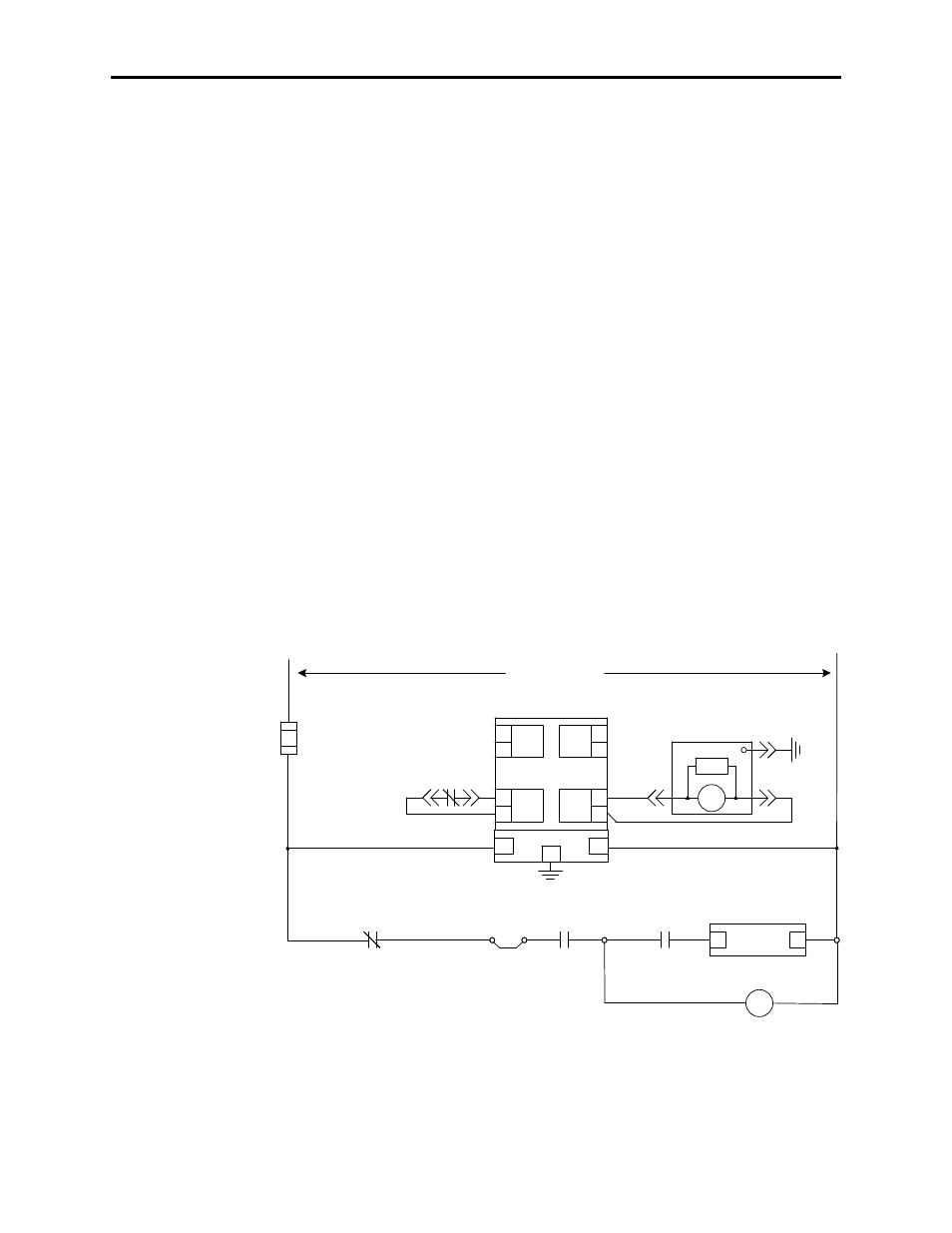

Control with Solid-State Devices

If control devices that employ electronic or suppressed output circuits are

used in the rung(s) that control the inputs to the IntelliVAC, alternate

arrangements may be required. Devices employing transistor or triac

output circuits have finite impedance and allow a leakage current to flow

in the blocking or off state. Some PLC and I/O modules with relay

outputs also have R-C snubber circuits across the contacts to suppress

noise generated during contact opening. The impedance of these circuits

also allows leakage current to flow when the contacts are open. The high

impedance input circuits of the IntelliVAC may be triggered by this

leakage current or residual terminal voltage, causing unintended

operation of the contactor, or maintenance of the closed state when the

control signal is removed.

This situation can be prevented by consideration of the control devices

when designing the control system. If PLC or similar control devices are

to be interfaced to the IntelliVAC, consider using relay outputs with no

suppression devices across the contacts (the IntelliVAC inputs are a high

impedance, resistive load). If this cannot be done, consider the leakage

current of the device to see if it is compatible with IntelliVAC inputs (see

Table 1.A). If not compatible, consider using an interposing relay

connected as shows in Figure 3.6.

-

+

3

2

12

11

AUX

MOV

M

TCO

5

6

-

+

1

EC

CCO

4

9

10

M

CLOSE

N

G

OVERLOAD

*

CONTROL

POWER

FUSE

CONTROL POWER

M

M -IV

M -IV

L

CR

CR

SOLID STATE

OUTPUT

INPUT POWER

*

Refer to Table 3.A for recommended fuse sizing.

Figure 3.6 – Control with Solid-State Devices