Rockwell Automation 1395 Discrete Adapter, Rev 3.XX-8.XX User Manual

Page 29

Chapter 5

StartĆUp

5-6

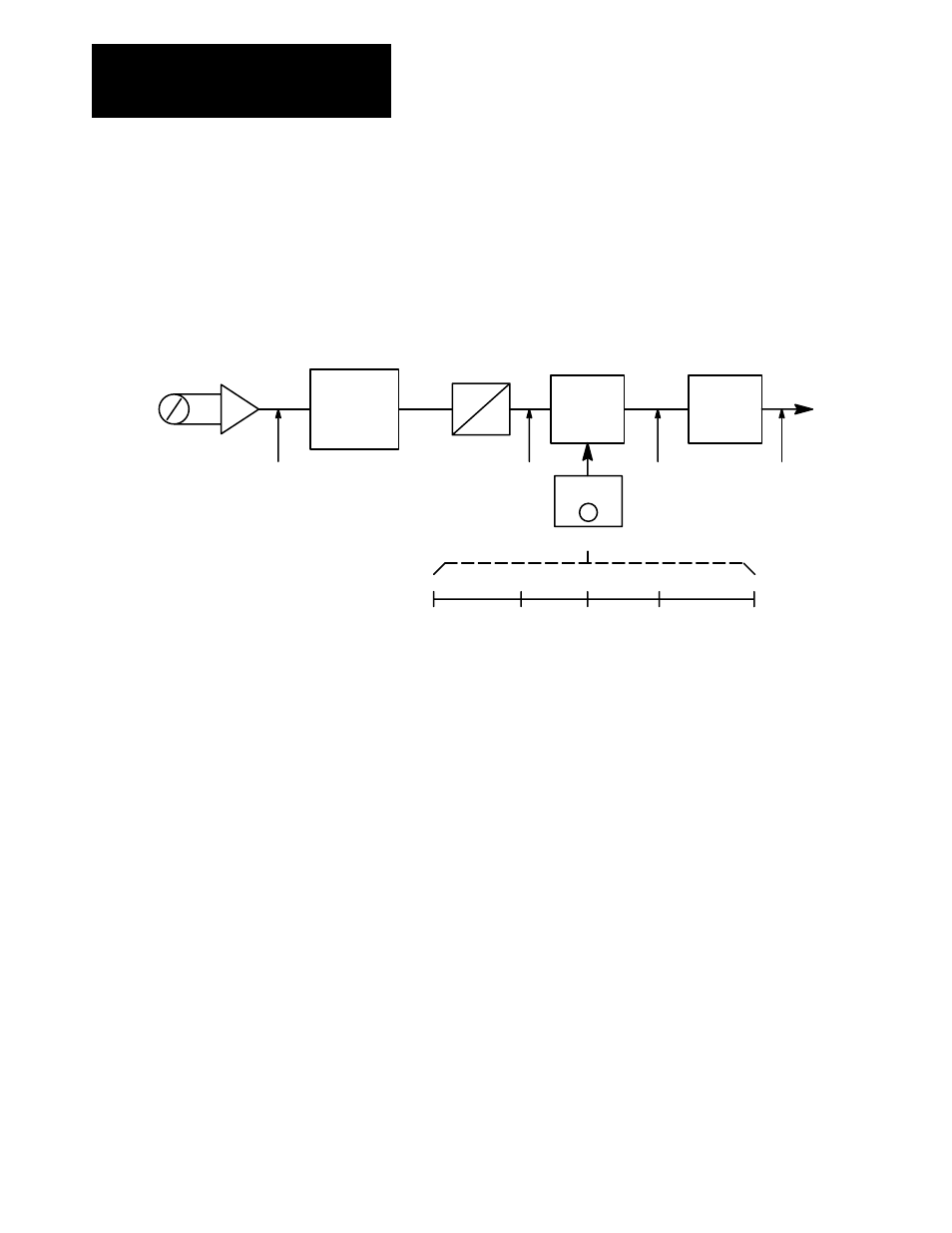

As seen in Figure 5.3, the offset voltage adds the corresponding digital

value to the range. In this case, an offset of –5 volts adds a digital value of

–1024 to the range. This causes 0 volts on the potentiometer to register as

–1024 digital internal to the Drive. This can then be scaled so that 0 volts

sends a digital value of –4096 for –100% Torque.

Figure 5.3

Example: Potentiometer 0 to 10V Range to Control

±

100% to

±

100% Torque Reference

-4096

+4096

0 to 10V

Pot

+0V

to

10V

Multiplexer

A

D

+/- 2048

Scale

X4

To P402

+0

-1024

+1024

Offset

P551 = -5V

Range of 20V

0V

0

0

5V

1024

Potentiometer

Digital Value

Offset by -5V

to

2048

5V = 100% T

Offset

+ 1024

X4

4096

-10V

10V

0

0

+10V

+2048

+1024

+4096

-1024

-4096

Adding -1024

Scale by 4

Analog outputs are set up similar to analog inputs. Each output has a scale

and offset parameter, along with a specific variable parameter used for

linking. Differences occur because of the direction of information flow.

The drive sends a digital value in drive units, which must be matched to the

voltage of the monitoring device. As in the analog inputs, the analog output

converts a

±

2048 to

±

10V DC. Thus, when the drive sends

±

100% Base

Speed (equal to

±

4096) it must be scaled by 0.5 to be in the proper range

(4096 x 0.5 = 2048). Offset can be

±

20V DC, even though the physical

limit is

±

10V DC. This allows you to offset the signal anywhere within the

entire range.