Specifications – Rockwell Automation 21G PowerFlex 755 Transition Section and Splicing Kit User Manual

Page 25

Rockwell Automation Publication 750-IN027C-EN-P - November 2013

25

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

Specifications

Tighten all bus connections with a torque wrench and socket according to

intervals established by your maintenance policy. If a torque wrench is not

available, tighten until the conical spring washer is flat. Do not grease or lubricate

the hardware.

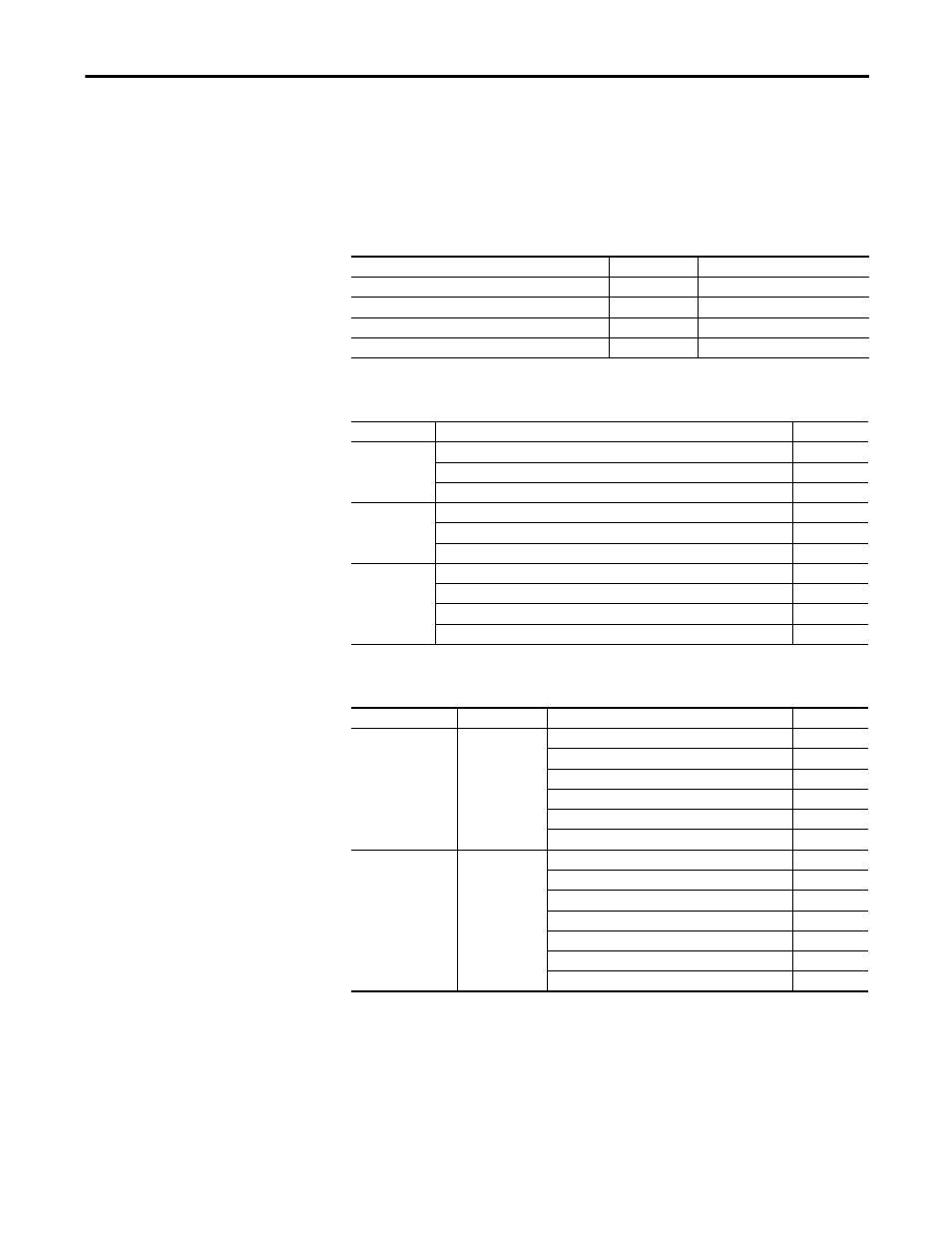

Table 1 - Torque Requirements

Table 2 - Horizontal Bus Required Splice Hardware

Table 3 - PE Bus Required Splice Hardware

Description

Hardware

Torque

Transition section to drive cabinet joining screws

M6

6.2 N•m (55 lb•in)

Transition section to MCC column joining screws

1/4-20

6.2 N•m (55 lb•in)

Protective earth (PE) conductor splice connection

1/4-20

7.3 N•m (65 lb•in)

Main horizontal bus-bar splice connection

3/8-16

38 N•m (336 lb•in)

Amp Rating

Description

Quantity

1200

3/8-16 x 1.38 in. bus clamp assembly

12

3/8 flat washer

24

3/8-16 one-piece nut and conical spring washer

24

2000

3/8-16 x 2.25 in. bus clamp assembly

12

3/8 flat washer

24

3/8-16 one-piece nut and conical spring washer

24

3000

3/8-16 x 2.25 in. bus clamp assembly

6

3/8-16 x 2.75 in. bus clamp assembly

6

3/8 flat washer

24

3/8-16 one-piece nut and conical spring washer

24

PE Bus Bar Width

Amp Rating

Description

Quantity

25.4 mm (1.0 in.)

1200 and 2000

762 mm (30 in.) 250 MCM cable

2

1/4-20 x 1.25 in. hex-head cap screw

1

1/4-20 x 1.0 in. hex-head cap screw

3

1/4 flat washer

7

1/4 conical spring washer

4

1/4-20 G5 hex nut

3

50.8 mm (2.0 in.)

2000 and 3000

762 mm (30 in.) 250 MCM cable

2

914 mm (36 in.) 250 MCM cable

1

1/4-20 x 1.25 in. hex-head cap screw

1

1/4-20 x 1.0 in. hex-head cap screw

6

1/4 flat washer

10

1/4 conical spring washer

7

1/4-20 G5 hex nut

5