Step 7: join horizontal bus and splicing bars – Rockwell Automation 21G PowerFlex 755 Transition Section and Splicing Kit User Manual

Page 20

20

Rockwell Automation Publication 750-IN027C-EN-P - November 2013

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

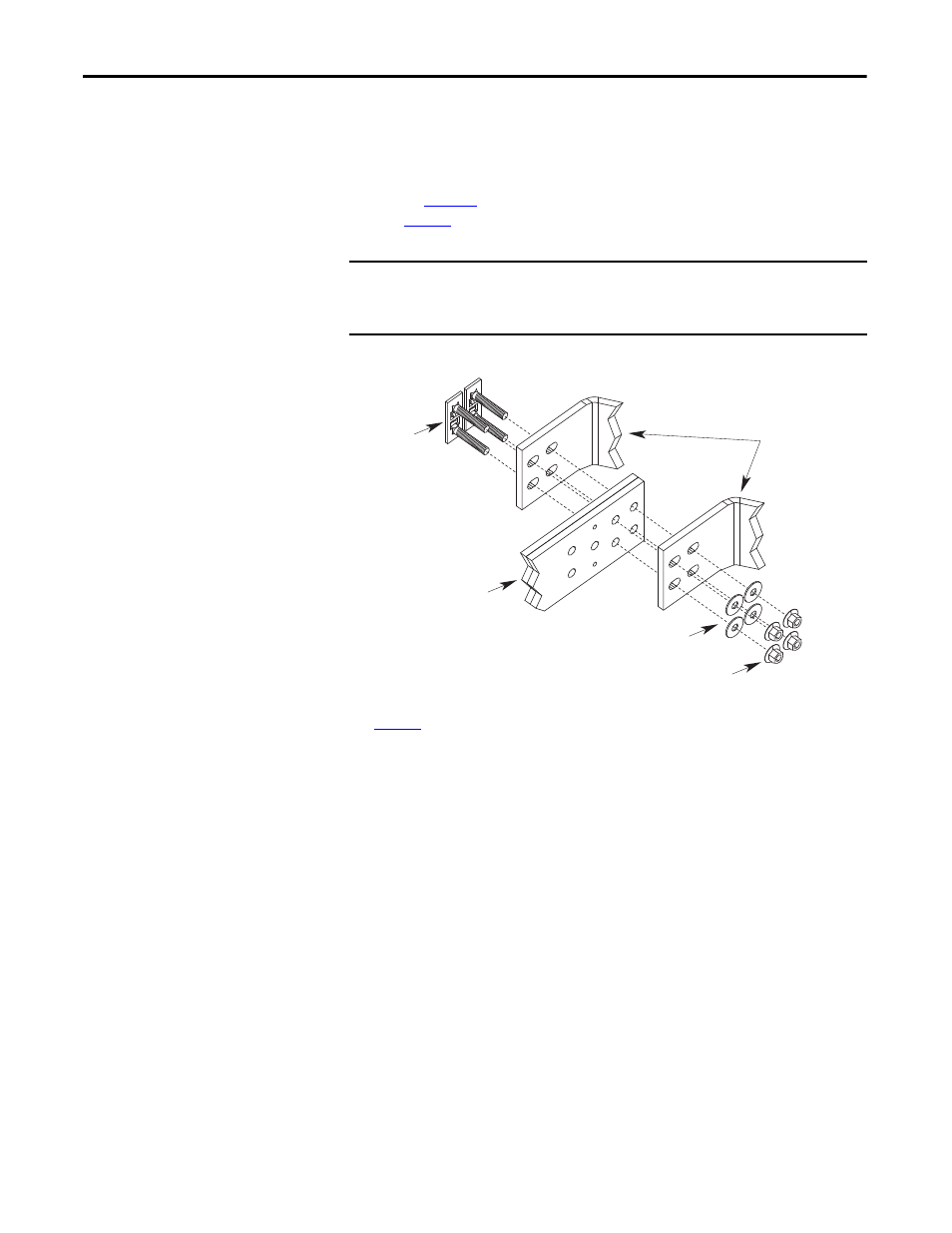

Step 7: Join Horizontal Bus and Splicing Bars

Splicing kits will contain either two or four sets of hardware per splice bar,

depending on the current rating of the horizontal bus. Assemble hardware as

depicted in

Figure 2

and uniformly tighten splice kit hardware to the final torque

listed in

Table 1

.

Figure 2 - Splicing Hardware Configuration Detail

See

Table 3

for main horizontal bus-bar splicing bar dimensions.

IMPORTANT

Note for NO-OX-ID: If you’re using corrosion inhibitor on bus bars, do not get

any on the bus splicing hardware. It will prevent the hardware from being

properly torqued. Damage may occur.

Main Horizontal Bus -bar

Main Horizontal

Bus-bar Splicing Bars

Flat Washers

One-Piece Nut and Conical Spring Washer

Bus Clamps

Front