Original instructions, Safety instructions—maintenance – Rockwell Automation 445L GuardShield Micro 400 Safety Light Curtain User Manual User Manual

Page 20

R

GuardShield™ Micro 400 Safety Light Curtain User Manual

18

Original instructions

Corrective steps

1. Examine connections, cables and plugs of transmitter and receiver.

2. Turn the supply voltage off and on again.

With the help of the optical interface, it is possible to display the

lock out information at a Laptop per USB interface.

If the LED of the safety light curtain is still blinking red, please

contact Rockwell Automation technical support.

Note: In cascaded systems only the LED in the first safety light

curtain will illuminate (closest to the safety controller).

Safety Instructions—Maintenance

For safety reasons all inspection results should be recorded.

Only persons, who clearly understand the functioning of the

GuardShield Micro 400 and of the machine, may carry out an

inspection.

If installer, planning engineer and operator are different people,

make sure that the user has sufficient information available to

carry out the inspection.

Daily Inspection

1. Approach to hazardous machine parts must only be possible

through the protective field of GuardShield Micro 400.

2. Operators cannot step through the sensing area while working

on dangerous machine parts.

3. The safety distance of the application is bigger than the

calculated value.

4. The optic front cover is neither scratched nor dirty.

Operate the machine and check, if the hazardous movement will

stop under the following circumstances.

5. The protective field is interrupted.

6. Hazardous machine movement stops immediately, if the

protective field is interrupted by the test rod directly in front of

the transmitter, directly in front of the receiver and in the

middle between transmitter and receiver.

7. No hazardous machine movement while the test rod is

anywhere within the protective field.

8. If the blanking function is activated, check all sections of the

protective field with the appropriate test piece.

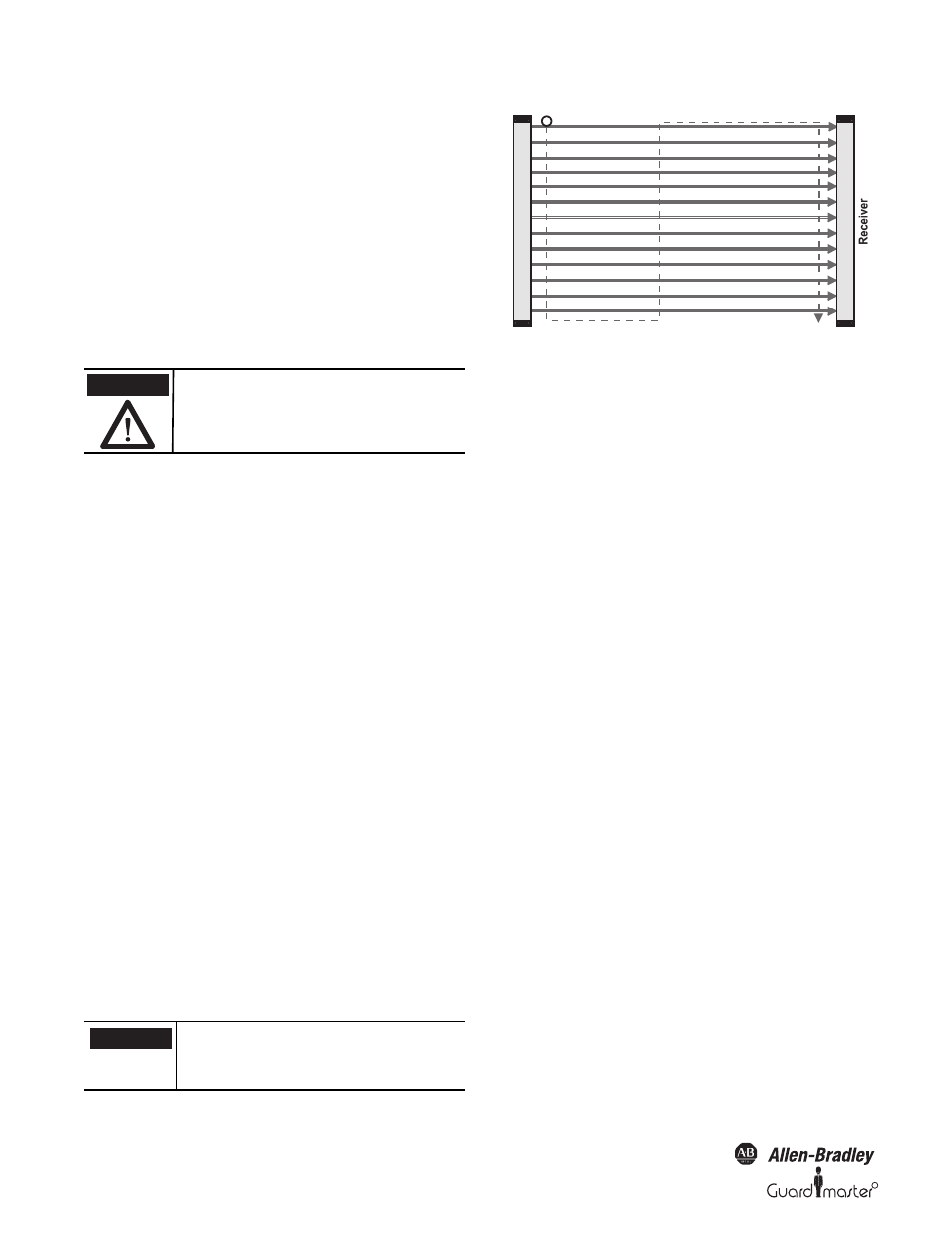

Figure 17: Proper testing of protective field using test rod

Six-Month Inspection

Check the following items:

• every six months or

• according local regulations or

• whenever a machine setting was changed.

1. Machine stops or does not obstruct any safety function.

2. The latest machine or connection modifications have no effect

on the control system.

3. The outputs of the controller of the GuardShield Micro 400 are

properly connected to the machine.

4. The total response time of the machine is shorter than the

calculated value.

5. Cables and plugs of the GuardShield Micro 400 are in good

condition.

6. Mounting brackets, caps and cables are properly secured.

Cleaning

If the optic front cover of the GuardShield Micro 400 is dirty or

scratched, the outputs turn off. Take a clean, soft cloth and rub

without pressure. Do not apply aggressive, abrasive or scratching

cleansing agents, which might attack the surface.

ATTENTION

Never operate the GuardShield Micro 400 before

carrying out the following inspection. Improper

inspection may lead to operator injury.

IMPORTANT

If any of the above conditions do not result in

the hazardous motion of the machine ceasing,

do not allow the protected machine to be

placed in operation.

Transmitter