Original instructions – Rockwell Automation 445L GuardShield Micro 400 Safety Light Curtain User Manual User Manual

Page 14

R

GuardShield™ Micro 400 Safety Light Curtain User Manual

12

Original instructions

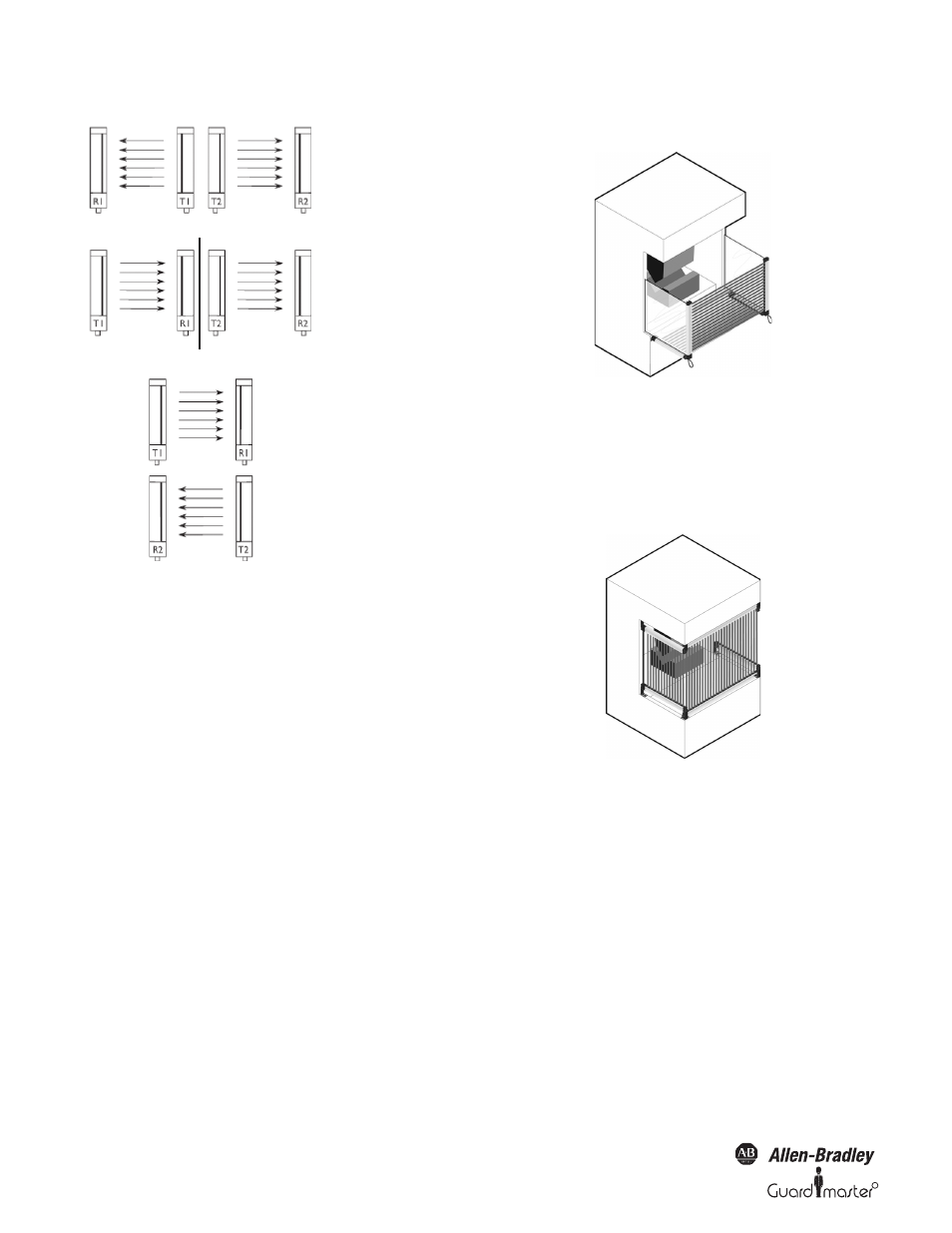

Figure 9: Multiple GuardShield Micro 400 alignment options

Cascaded GuardShield Micro 400

Configuration of Operating Modes in Cascading Systems

All of the operating modes of a cascaded GuardShield Micro 400

can be configured at the MSR42 control unit.

Two Segment Cascading GuardShield Systems

When the safety distance calculation requires that a GuardShield

pair is vertically mounted at a distance that would allow a person

to stand between the vertical pair and the machine hazard, a

means of detection of that person is required.

There are a few methods of detecting the presence of a person

who could be standing in front of the machine hazard but inside

of the light curtain; installing a safety mat or safety laser scanner

are possible solutions, however, they are costly solutions as these

are separate safety systems that need to be integrated to the

safety circuit. The most cost-effective solution is to interconnect

an additional light curtain in series to the vertical pair. This is

accomplished by first selecting a cascading pair of GuardShield

Micro 400 safety light curtains with a protective height and

resolution based upon the results of a risk assessment. It is then

necessary to select the horizontal protected height of the pair of

GuardShield Micro 400 light curtains. This pair should provide

detection from the vertical pair to the front of the machine

hazard. In most cases this pair of GuardShield Micro 400 can be 30

mm resolution as their purpose is to detect the presence of a

person, not a person’s fingers or hands.

The next step is to select the interconnect patchcords for the

transmitter and receiver. These patchcords are offered in a variety

of lengths (“Table 6: Available cable types” on page 14). The final

cascading segment which is not connected to another pair of

GuardShield Micro 400 light curtains is equal to a standard

GuardShield Micro 400 light curtain.

Figure 10: “L-shaped” two segment GuardShield Micro 400 cascading systems offer

protection when it is possible to stand between the vertical light curtain and the machine

hazard

Three Segment GuardShield Cascading Systems

When the use of corner mirrors is not practical or possible, three-

sided guarding of a machine hazard is possible using cascading

GuardShield Micro 400 light curtains.

Figure 11: Top and bottom mounting of three GuardShield Micro 400 segments is possible,

which will provide three-sided machine guarding without the use of corner mirrors

Transmitters emit in

opposite direction. Each

receiver receives only the

beams of the appropriate

transmitter.

Transmitters emit in same

direction:

Optical (physical) barrier

necessary

Positioning of the light

curtain: Transmitters emit in

opposite direction.