Min. through a fairly typical value of 0.20 g/cm, Min. to a practical minimum of 0.08 g/cm, Min. to 0.3 g/cm – USG Plasters and Gypsum Cements for the Ceramic Industry User Manual

Page 2

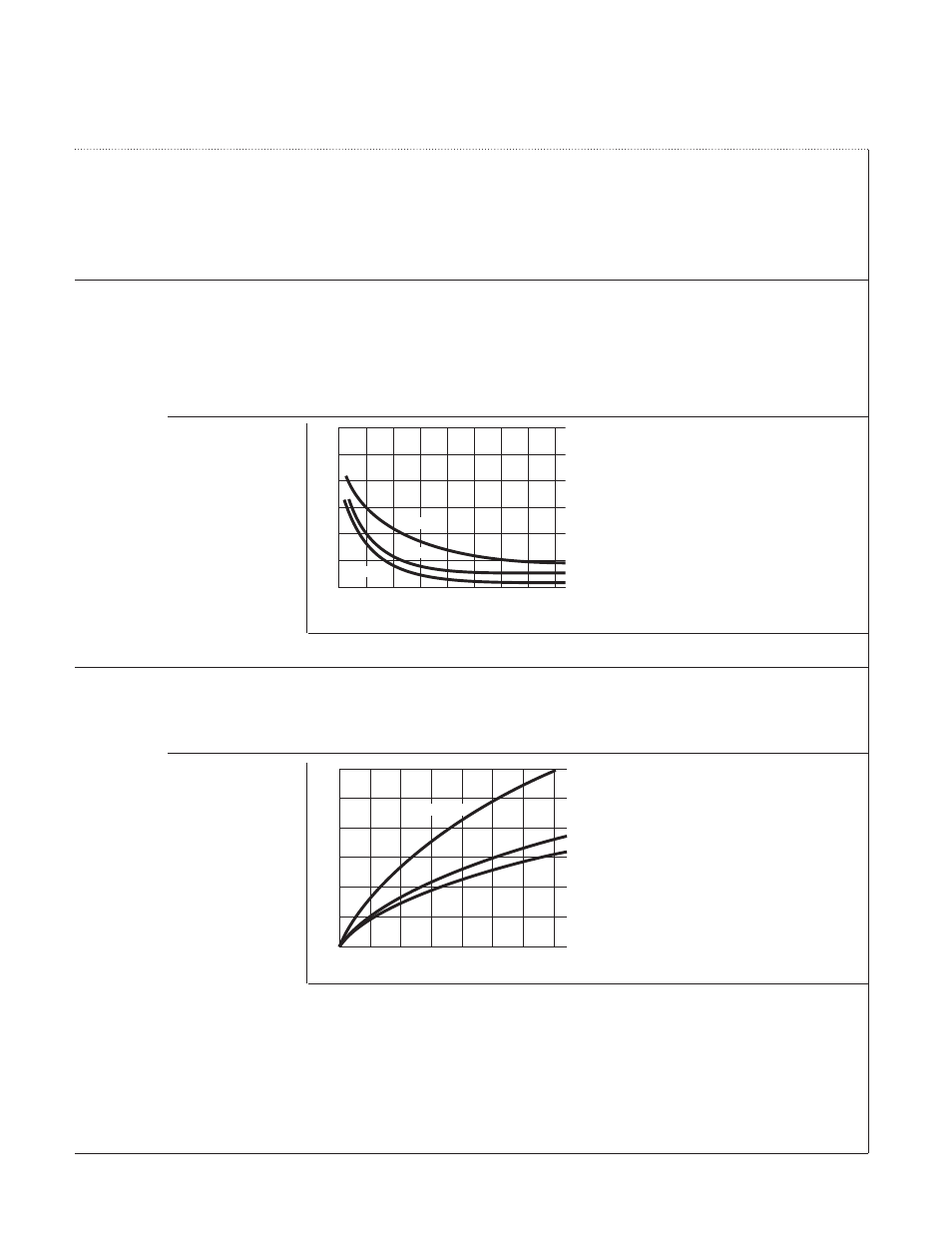

The data in Fig. 1 indicates how fast water may be taken up by a casting mold in various shop conditions.

The maximum rate of absorption varies from approximately 0.38 g/cm

2

/min. through a fairly typical value of

0.20 g/cm

2

/min. to a practical minimum of 0.08 g/cm

2

/min. It is important to note that a major determinant

of absorption rate is the amount of free water present in the mold. Fig. 1 demonstrates the importance of optimum

mold “conditions.” With typical water-to-plaster ratios, the presence of 5% free water reduces the rate of absorption

approximately 50%. It generally is good practice to have a minimum of 5% free water, and many shops have as

much as 15%.

Figure 1: Effect of

consistency and free

water in sample on the

rate of water absorption

during immersion.

Free Water and

The presence of free water markedly reduces the absorptive rate of a given mold, and best results are achieved

Absorptive Rate

only when proper allowances are made. The best method of conditioning a mold is to dry it to a constant weight at

110 °F, then dip it in water for a few seconds to a few minutes. Fig. 2 indicates the time required to condition a plaster

mold to perform in the range of the flat part of the curve shown in Fig. 1.

Figure 2: Accelerated

absorption during

initial immersion.

If the character of the slip is reasonably uniform and shop conditions are optimum, it is possible to determine free

water content by weighing well-performing molds, then using this figure as a guide for the entire shop. A more

practical procedure is to ascertain the maximum safe rate at which water can be released by the slip, then

adjust both the consistency of the mold and the free water contained in it to determine a compatible absorptive

rate. Plaster casting bodies probably will not release water safely much faster than about 0.2 g/cm

2

/min.

to 0.3 g/cm

2

/min.

.0

0

water in mold (percent of dry weight)

a

b

so

rp

ti

o

n

ra

te

(g

/c

m

2

/m

in

.)

.1

.2

.3

.4

.5

.6

5

10

15

20

25

30

35

40

80 con

66 con

100 con

0

0

time of immersion (minutes)

w

a

te

r

a

b

so

rp

ti

o

n

(p

e

rc

e

n

t

d

ry

w

e

ig

h

t)

2

4

6

1

3

5

7

5

10

15

80 con

66 con

100 con

2