Installation, I nstallation checklist, Materials required – Regency Energy E18 Small Gas Insert User Manual

Page 10: Venting

10

Regency

®

E18 Gas Fireplace Insert

INSTALLATION

INSTALLATION CHECKLIST

1. Verify the model of the existing appliance you

are installing into is one of the following ap-

proved units:

Montigo

EP28-2

Montigo

EP28-4

Montigo

EP28-5

Montigo

EP28-S2

Montigo 36SR (Non powervent unit)

Montigo

28F-2

Montigo

28-F

Firesong

220N

Firesong

120N

2. Verify all clearances are at least the specifi ed

clearances.

3. Inspect existing venting and appliance for signs

of wear and durability.

4. Determine the route for the electrical for

the circulation fan. The circulation fan is not

optional.

5. Determine the route for the gas supply. The valve

has a 1/2" Male Flare on the left side of the E18.

Some modifi cation may need to be made to a

hard lined gas supply to connect to the E18.

6. Clean out the existing appliance of all dust and

debris.

7. Make the appropriate modifi cations to the existing

appliance specifi ed in the "Existing Appliance

Modifi cation" section of the manual. Make sure

when done there are no sharp edges exposed

to a person during operation of the unit.

8. Unpack the E18 from the box and disassemble.

9. Install the E18 into the existing unit as per

instructions.

10. Connect Gas Supply.

11. Connect Circulation Fan Power Cord.

12. Test Fire the E18 and check gas pressures

and confi rm Circulation Fan begins operation

with 10 minutes of fi ring the unit.

13. Check draft hood for spillage as per instructions.

14. Install Trim Kit as per instructions.

MATERIALS REQUIRED

Electrical power supply is required for the circulation

fan A 120 Volt AC power cord is hooked up to the

fan. Plug the 3 wire cord into a suitable recepta-

cle. Do not cut the ground terminal off under any

circumstances. When connected with 120 volts,

the appliance must be electrically grounded in ac-

cordance with local codes, or in the absence of local

codes, with the current Canadian Electrical Code

CSA C22.1 (in Canada) or with the current National

Electrical Code ANSI/NFPA 70-1987 (in U.S.A.).

NOTE: This unit is equipped with a heat sensor

thermodisc which will prevent the blower

from operating until the unit reaches the

correct temperature.

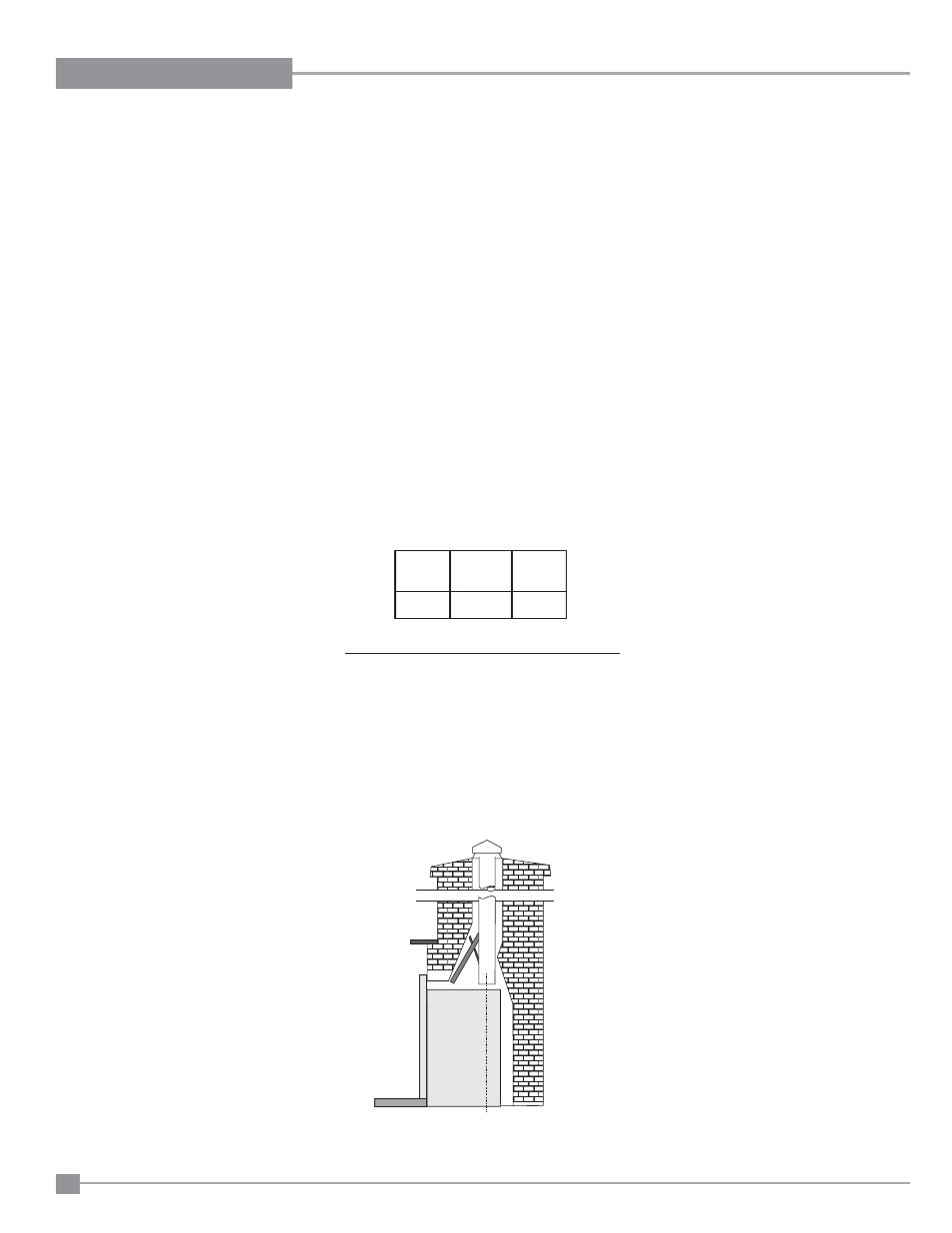

Height

Depth

Width

23-3/8"

12-1/2"

32"

MINIMUM FIREPLACE

OPENING FOR

MASONRY AND FACTORY

BUILT FIREPLACES

The minimum fi replace opening for this Regency

gas insert are listed below.

VENTING

T H E A P P L I A N C E M U S T N O T B E

CONNECTED TO A CHIMNEY FLUE

SERVING A SEPARATE SOLID FUEL

BURNING APPLIANCE.

This appliance is designed to attach to a 4" diameter

type B-Vent or double thickness approved aluminium

fl ex liner.

The fl ue collar of the appliance will fi t inside a

standard vent and may be fastened directly to the

vent using a minimum of 3 sheet metal screws or

a B-Vent, single wall vent connector.

B-Vent chimneys require a 1" clearance to com-

bustibles.

The Regency

®

Insert incorporates its own internal

draft hood, so no additional external draft hood is

required. Check periodically that the vent is unre-

stricted and an adequate draft is present when the

unit is in operation.

Before installing the vent system ensure that the

damper plate is locked into the open position and

secure to prevent the damper plate from falling

down and crushing the liner.

The appliance is equipped with a vent safety shutoff

system and a safety control system designed to

protect against improper venting of combustion

products. The appliance will not function without

being connected to a proper system.

WARNING: Operation of this heater when

not connected to a properly installed and

maintained venting system or tampering

with the vent shut-off system can result

in carbon monoxide (CO) poisoning and

possible death.

This appliance must not be connected to a chimney

fl ue serving a separate solid fuel burning appliance.

For best venting performance, we recommend the

following venting rules:

1. Use only certifi ed Type B gas vent or approved

fl ex liner.

2. Follow the vent manufacturer's instructions and

clearance requirements.

3. Observe any local code restrictions, if any,

regarding the installation of gas inserts.

4. Use as few elbows as possible.

5. Keep horizontal lengths as short as possible

and maintain at least an upward slope of 1/4 in.

(6.4mm) for every 12 in. (305mm) of horizontal

run.

6. Terminate the vent with a suitable certifi ed

vent cap.