MTS 318 Load Unit User Manual

Page 89

Routine Maintenance Overview Checklist

318 Load Unit

Maintenance

89

3. Check the alignment.

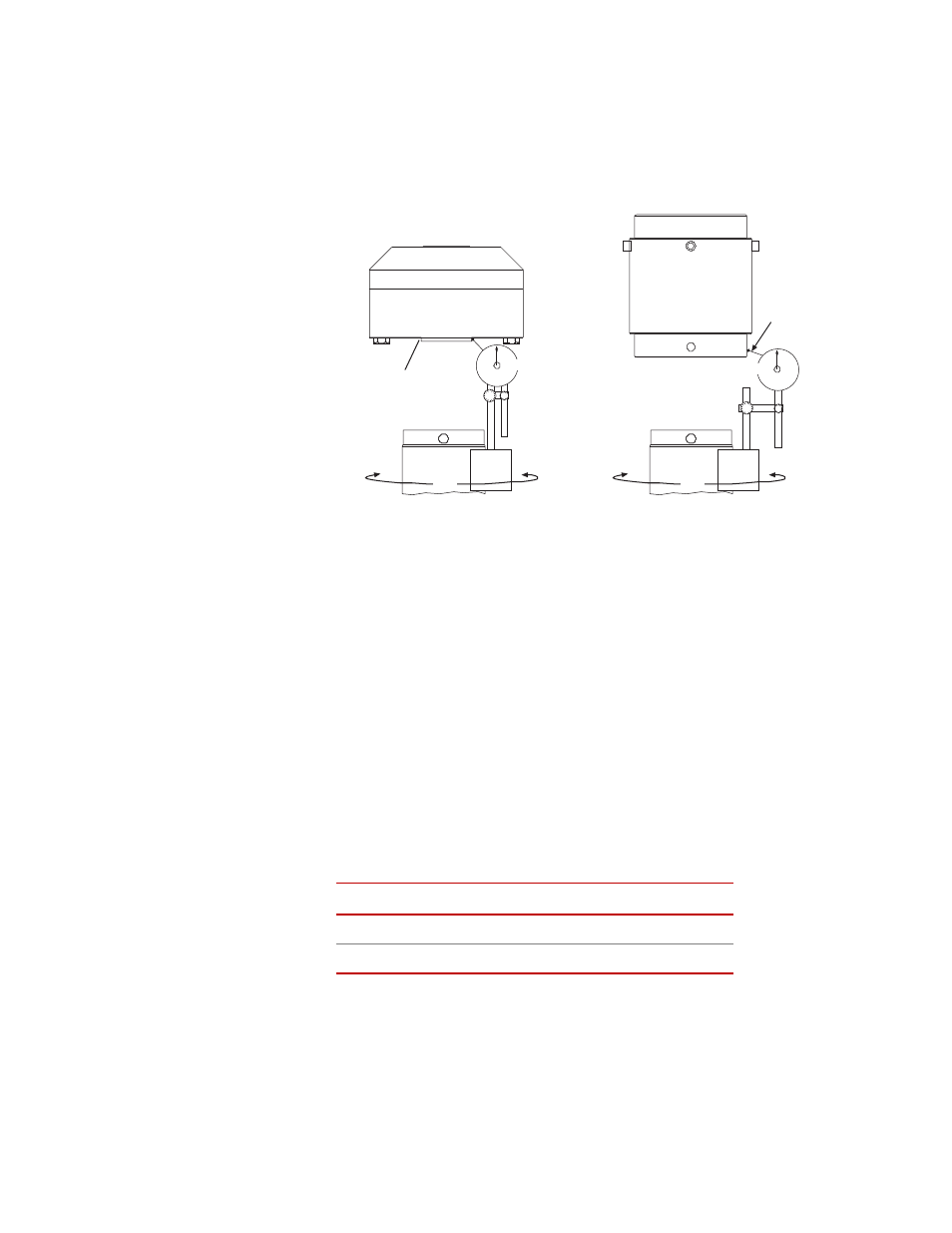

In this step, you check the alignment between the force transducer and the

actuator.

.

Attaching and Zeroing the Indicator

A. Attach the dial indicator to the actuator.

On a low profile force transducer, adjust the indicator to take the

reading along the edge of the loading surface.

On cylindrical style force transducers, adjust the indicator so that its

stylus just touches the polished bottom edge of the transducer.

B. Zero the indicator.

C. Slowly turn the actuator to rotate the indicator 360

° around the force

transducer.

Stop frequently to take indicator readings. Keep your hands off the

actuator and indicator when taking the readings. Compute the total

indicator runout (TIR). Take the maximum dial indicator reading and

subtract the minimum dial indicator reading.

D. If the TIR is 0.038 mm (0.0015 in) or less, the force transducer is

accurately aligned with the actuator. Go to Step 6.

If the TIR is greater than 0.038 mm (0.0015 in), the force transducer

needs to be aligned with the actuator. Start over with Step 3.

L

OAD

U

NIT

R

ATING

TIR

250 kN (55 kip) or less

>0.038 mm (0.0015 in)

500 kN (100 kip)

0.051 mm (0.0020 in)

360°

360°

Read

along

the edge

Read

along

the edge

Zero

Zero