318 load unit: crush point hazards, 318 load unit: specimen installation – MTS 318 Load Unit User Manual

Page 62

318 Load Unit

62

Operation

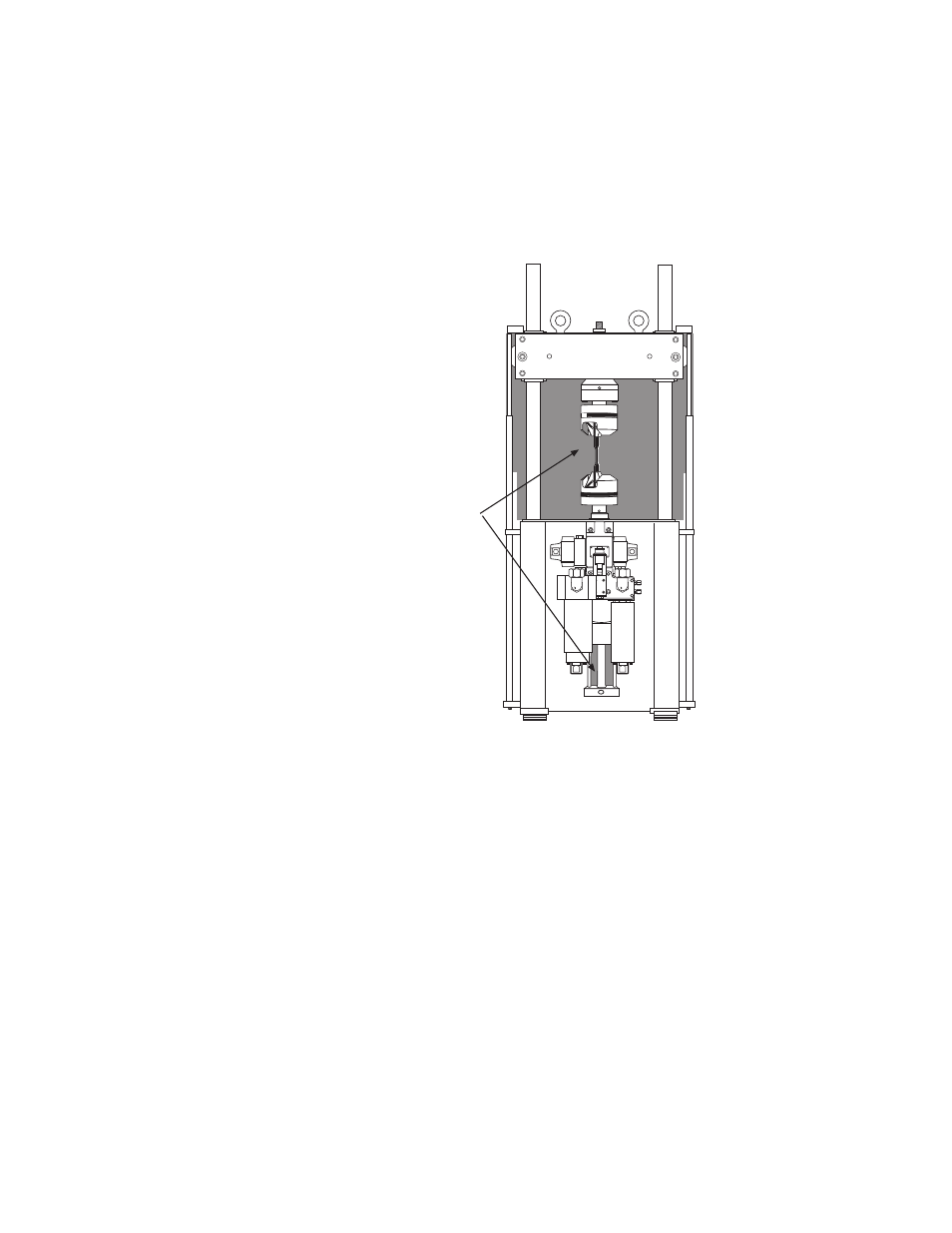

318 Load Unit: Crush Point Hazards

It is important to stay clear of any potential crush points when the system is

operating. Know where the crush points are in your system and protect yourself

and others from those crush points with appropriate safety devices. The

following paragraphs describe crush points and precautions to take while

working around crush points.

Locations

A crush point exists between the platen and crosshead on load units where the

actuator piston rod and specimen move (both areas are shown). Another potential

crush point exists where the lower end of the actuator piston rod extends below

the platen and the bottom of the load unit/load frame.

Precautions

Keep clear of any mechanical linkage that moves within a closed area. If the

linkage should move (when the system starts or due to mechanical failure), very

high forces can be present that could pinch, cut, or crush anything in the path of

linkage movement.

Never allow any part of your body to enter the path of machine movement or to

touch moving machinery, linkages, hoses, cables, specimens, etc. These present

serious crush points or pinch points.

318 Load Unit: Specimen Installation

The procedure to install a specimen varies due to the variety of test fixtures,

grips, and the type of specimen being installed. This section should be considered

a guideline. You need to modify this procedure to suit your equipment.

647 Hydraulic Wedge Grip

647 Hydraulic Wedge Grip

Crush

point

areas