318 load unit: maintain airmount pressures, 318 load unit: maintain airmount pressures 80 – MTS 318 Load Unit User Manual

Page 80

318 Load Unit

80

Routine Maintenance Overview Checklist

Maintenance

318 Load Unit: Maintain Airmount Pressures

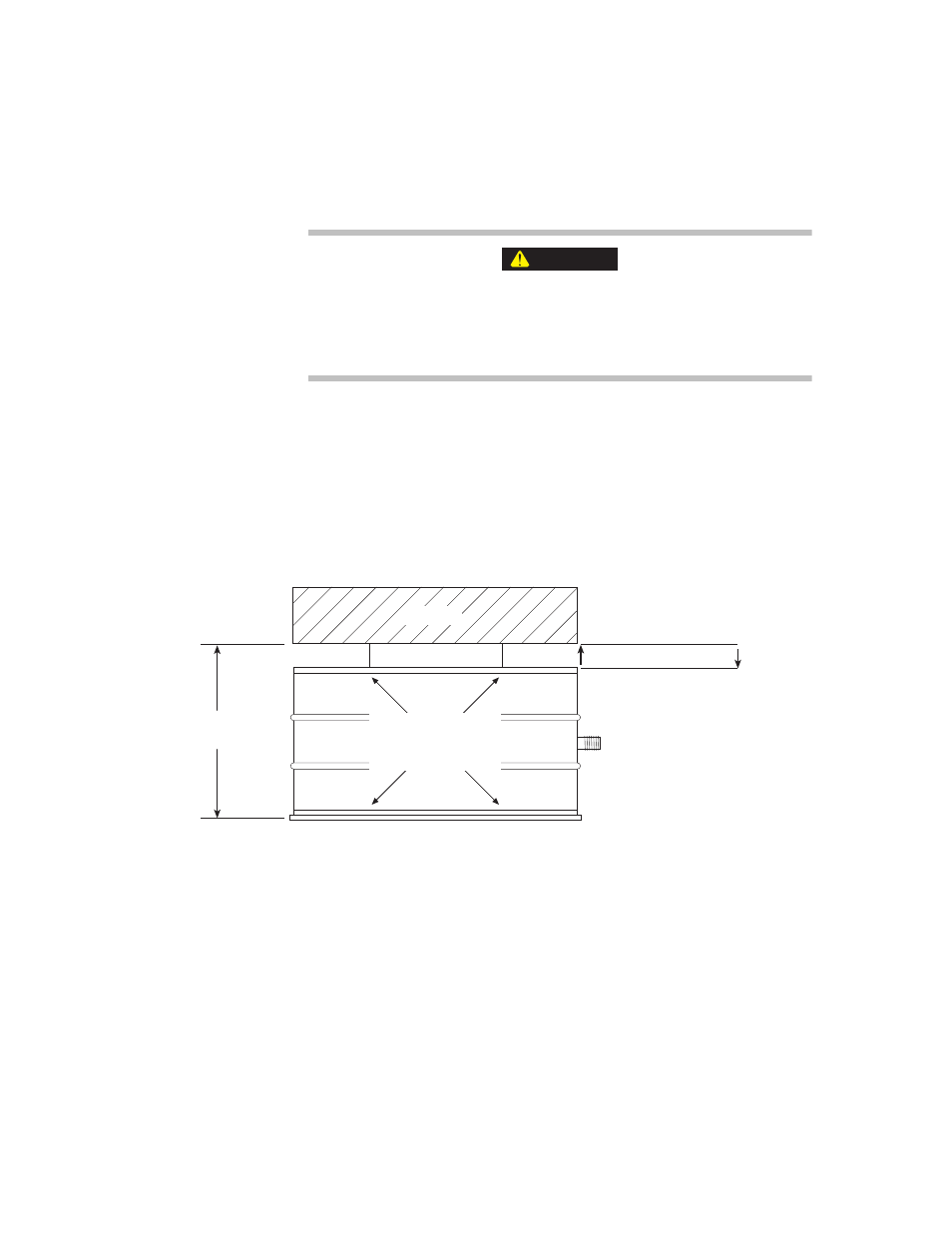

Optional inflatable airmounts reduce vibration and noise. They are installed

under the feet of the load unit. Inflation pressures must be maintained to both

level and isolate the load unit.

Airmounts can be overinflated and then explode.

You can be seriously hurt if an airmount explodes, sending fragments flying.

Do not overinflate the airmounts.

1. Check the inflation pressures on each airmount. Bleed any airmount whose

pressure is above 0.55 MPa (80 psi).

2. Check the airmounts’ inflated heights. They should be between

83–86 mm (3.25–3.5 in).

If the load unit is level and the airmount heights correct, you are done.

If not, continue this procedure.

3. Gradually inflate or deflate each airmount in 5 mm (0.20 in) steps as

required to level the load unit.

Ensure that airmount pressures do not rise above 0.55 MPa (80 psi) and

heights do not rise above 86 mm (3.5 in).

4. After leveling the load unit, check that the height of each airmount is

between 83–86 mm (3.25–3.5 in).

5. If any airmount pressures are above 80 psi (0.55 MPa) or any airmount

heights not between 83–86 mm (3.25–3.5 in), repeat Steps 1–3 until the load

unit is level.

WARNING

(80 psi)

0.55 MPa

8386 mm

(3.253.5 in)

5 mm (0.20 in)

Maximum pressure

steps